Lead-acid battery nano carbon activating agent

A lead-acid battery, carbon activation technology, applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery gas removal, etc., can solve the problems of battery charging, loss of function, battery scrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

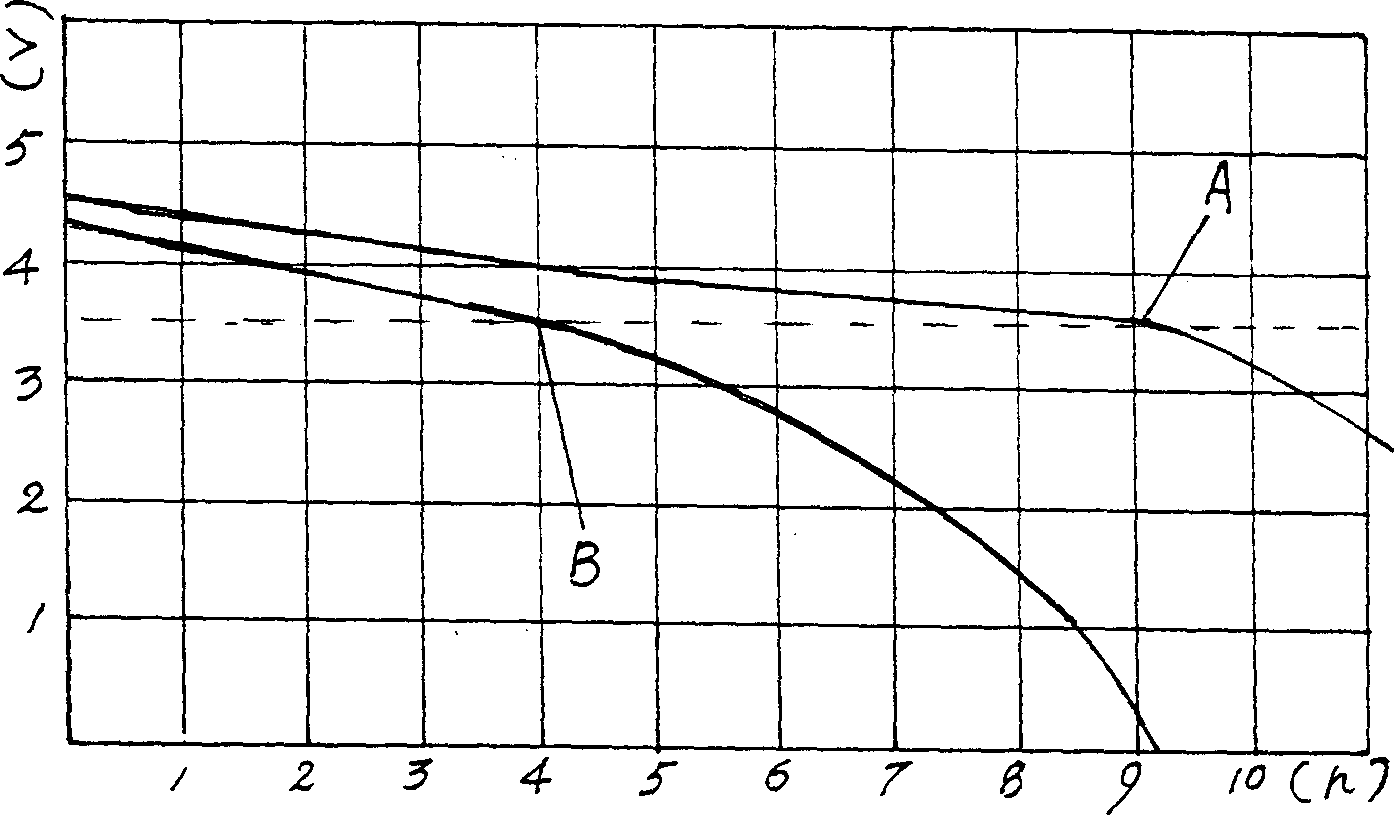

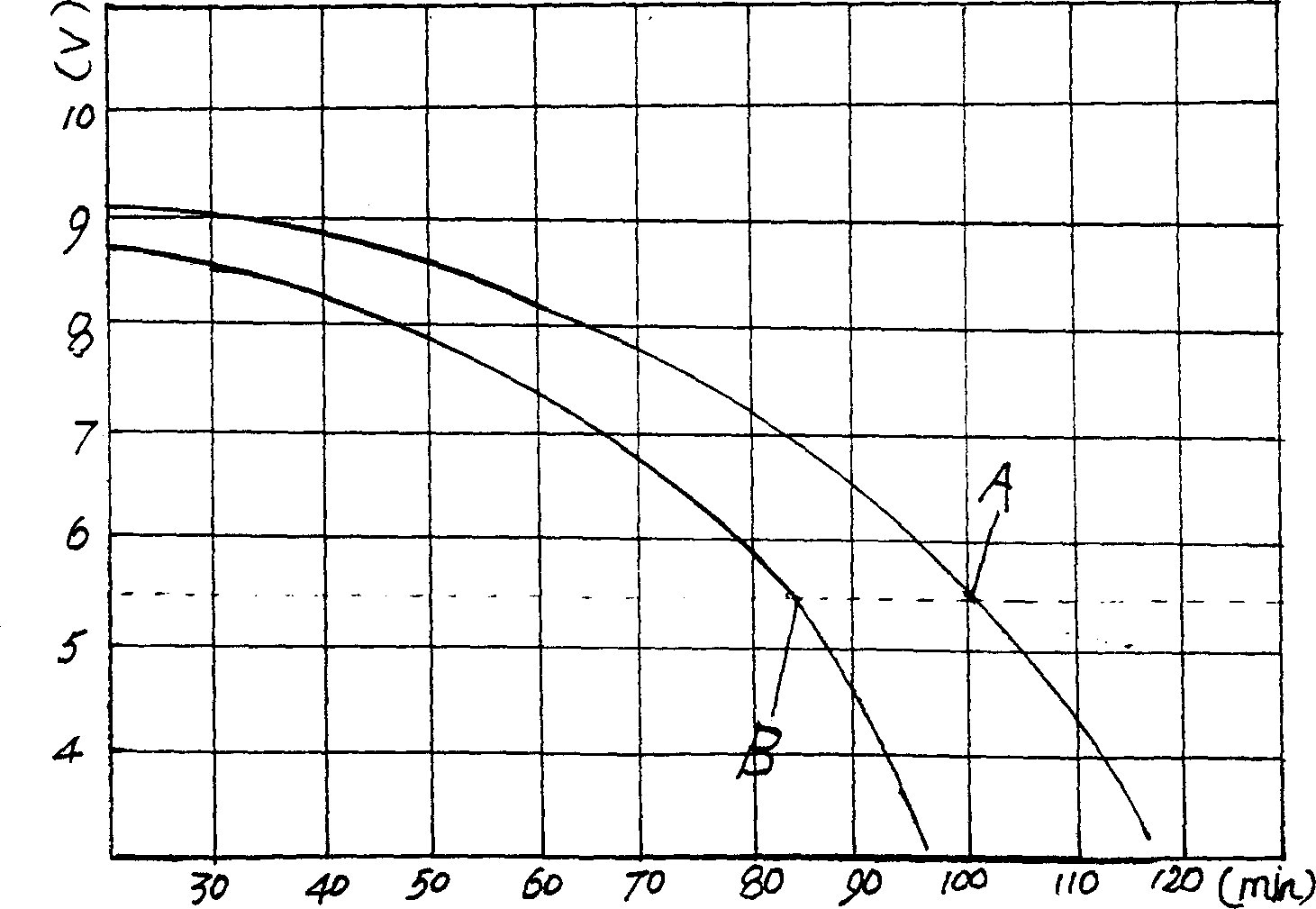

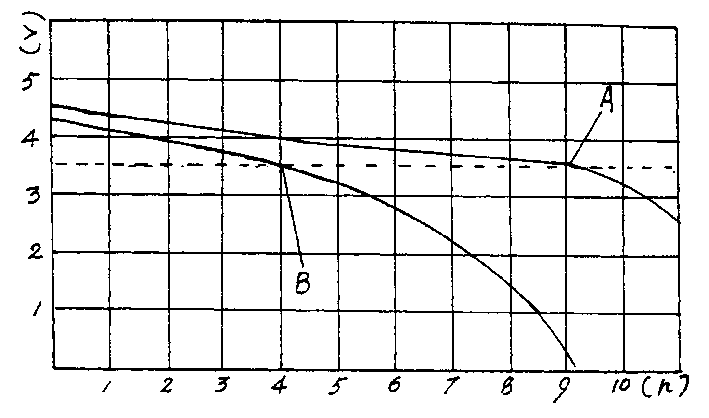

[0016] Example 2. Fill a 6-QA60 new lead battery with 20 milliliters of activator per grid

[0017] Liter, 6 grids, a total of 120ml, with normal charging for 12 hours, under the same conditions

[0018] The discharge time of adding activator is 100 minutes, and the discharge without filling is 84

[0019] Minutes, according to the comparison above, the capacity of the lead battery injected with carbon activator increases by more than 15%.

[0020] superior. use see Figure II The voltage versus time curve is shown.

[0021] Description of drawings: (V) in the figure represents voltage volts, (h) in the figure is hour, (min) minute in the figure, figure A represents the curve of adding carbon activator, and figure B represents the curve of not filling carbon activator .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com