Apparatus for making frequency-variable grating using holographical method

A holographic method and grating technology, applied in the field of frequency conversion grating, can solve the problem that the spatial frequency cannot be made very high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

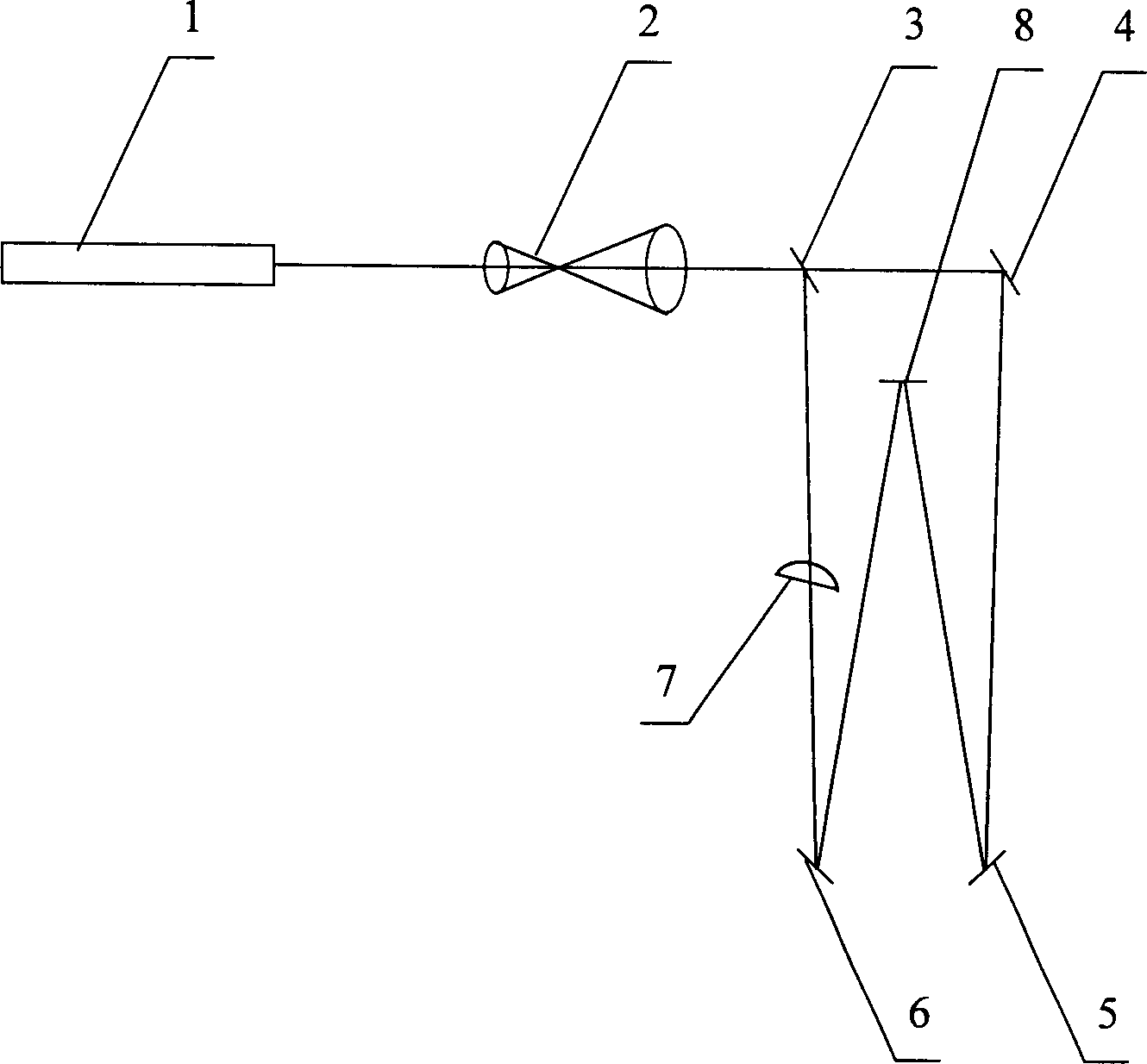

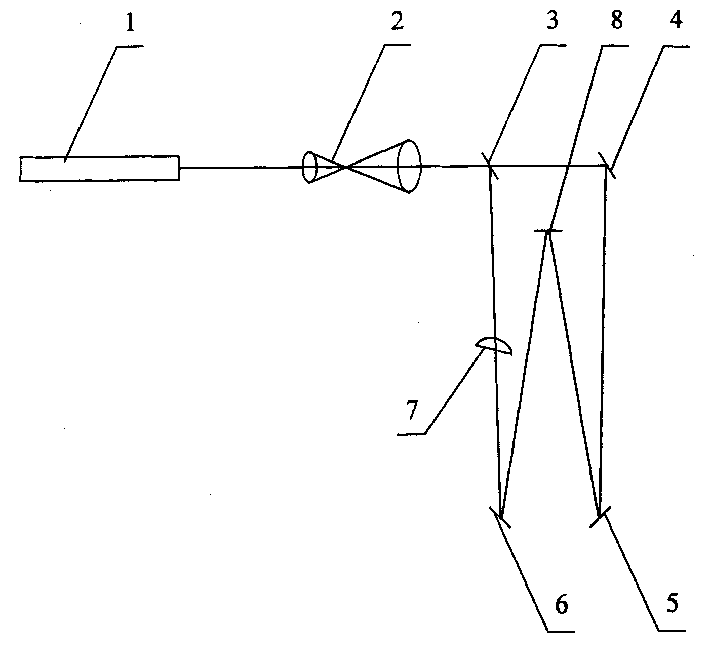

[0037] The holographic method of the present invention makes frequency conversion grating device such as figure 1 As shown, it consists of a laser light source 1, a telescope 2, a beam splitter 3, mirrors 4, 5, 6, a cylindrical mirror 7 and a recording medium 8, and its specific

[0038] The parameters of the embodiment are as follows:

[0039]Laser source 1 is a single-mode He-Ne laser with an output power of 5mW; telescope 2 is a beam expander system with a magnification of 100 times, and its function is to expand the beam with a diameter of 1mm into a beam with a diameter of 100mm; Beamer 3 is a wedge-shaped plate with a reflectivity of 50%, which is used to split the light coming out of the telescope into two, one beam is the reference wave Cb, and the other beam is the object wave Wb.

[0040] Mirrors 4, 5, 6 are total reflection mirrors, and the light beam Wb reflected from beam splitter 3 arrives at mirror 6 through cylindrical mirror 7 and is reflected on recording me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com