Ferrous phosphate hydrated salt crystal, producing method thereof and method for producing Li-Fe-P composite oxides

A composite oxide and ferrous phosphate technology, applied in the direction of phosphorus compounds, iron compounds, chemical instruments and methods, etc., can solve the problems of developed crystallization, difficult processing such as crushing, and difficult expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Dissolve 907g (3mol) of ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) and 261g (2mol) of 75% phosphoric acid (H 3 PO 4 ) to make a mixed solution (temperature 17°C, pH 1.6). 1500 ml (6 mol) of 16% sodium hydroxide (NaOH) aqueous solution was dropped into the mixed solution over 18 minutes at a rate of 83 ml / min to precipitate ferrous phosphate (temperature 31° C., pH 6.7).

[0106] Next, ferrous phosphate was recovered by filtration, and the recovered ferrous phosphate was carefully washed with 4.5 L of water.

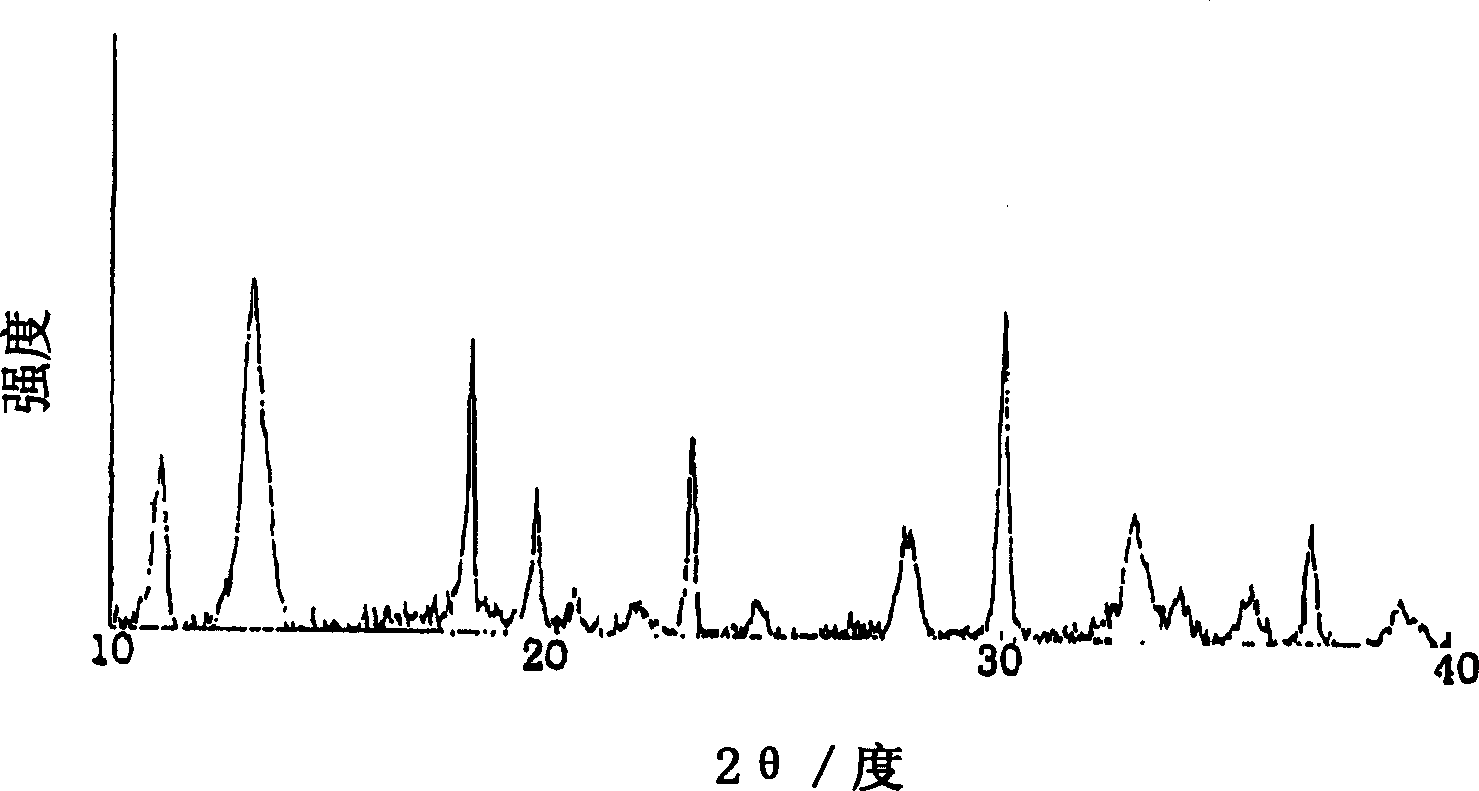

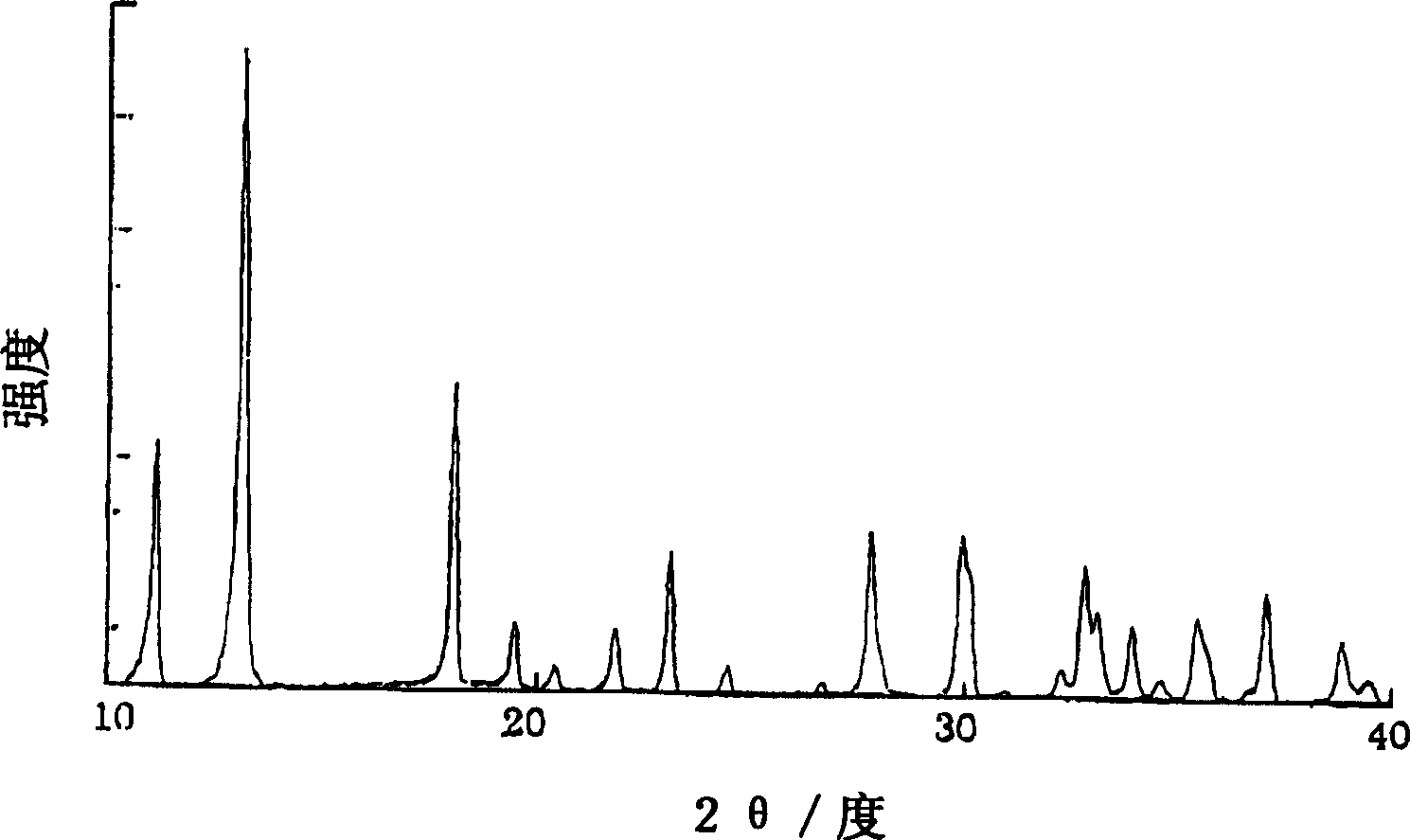

[0107] Next, the washed ferrous phosphate was dried at a temperature of 50° C. for 23 hours to obtain 490 g of a dry product. The resulting dried product was analyzed by X-ray diffraction. As a result, the diffraction pattern was consistent with JCPDS (Joint Committee on Powder Diffraction Standards) figure number 30-662, so it was confirmed that the dried product was Fe 3 (PO 4 ) 2 ·8H 2 O (98% yield).

[0108] The resulting Fe is shown in Table 2 3 (...

Embodiment 2

[0112] Dissolve 816g (2.7mol) of ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) and 261g (2mol) of 75% phosphoric acid (H 3 PO 4 ) to make a mixed solution (temperature 8°C, pH 0.6). 1000 ml (6 mol) of 24% sodium hydroxide (NaOH) aqueous solution was dropped into the mixed solution over 6 minutes at a rate of 166 ml / min to precipitate ferrous phosphate (temperature 21° C., pH 7.4).

[0113] Next, ferrous phosphate was recovered by filtration, and the recovered ferrous phosphate was carefully washed with 4.5 L of water.

[0114] Next, the washed ferrous phosphate was dried at a temperature of 50° C. for 23 hours to obtain 480 g of a dry product. The obtained dried product was analyzed by X-ray diffraction. As a result, the diffraction pattern was consistent with JCPDS (Joint Committee on Powder Diffraction Standards) figure No. 30-662, so it was confirmed that the dried product was Fe 3 (PO 4 ) 2 ·8H 2 O (94% yield).

[0115] The resulting Fe is shown in Table 2 3 (PO ...

Embodiment 3

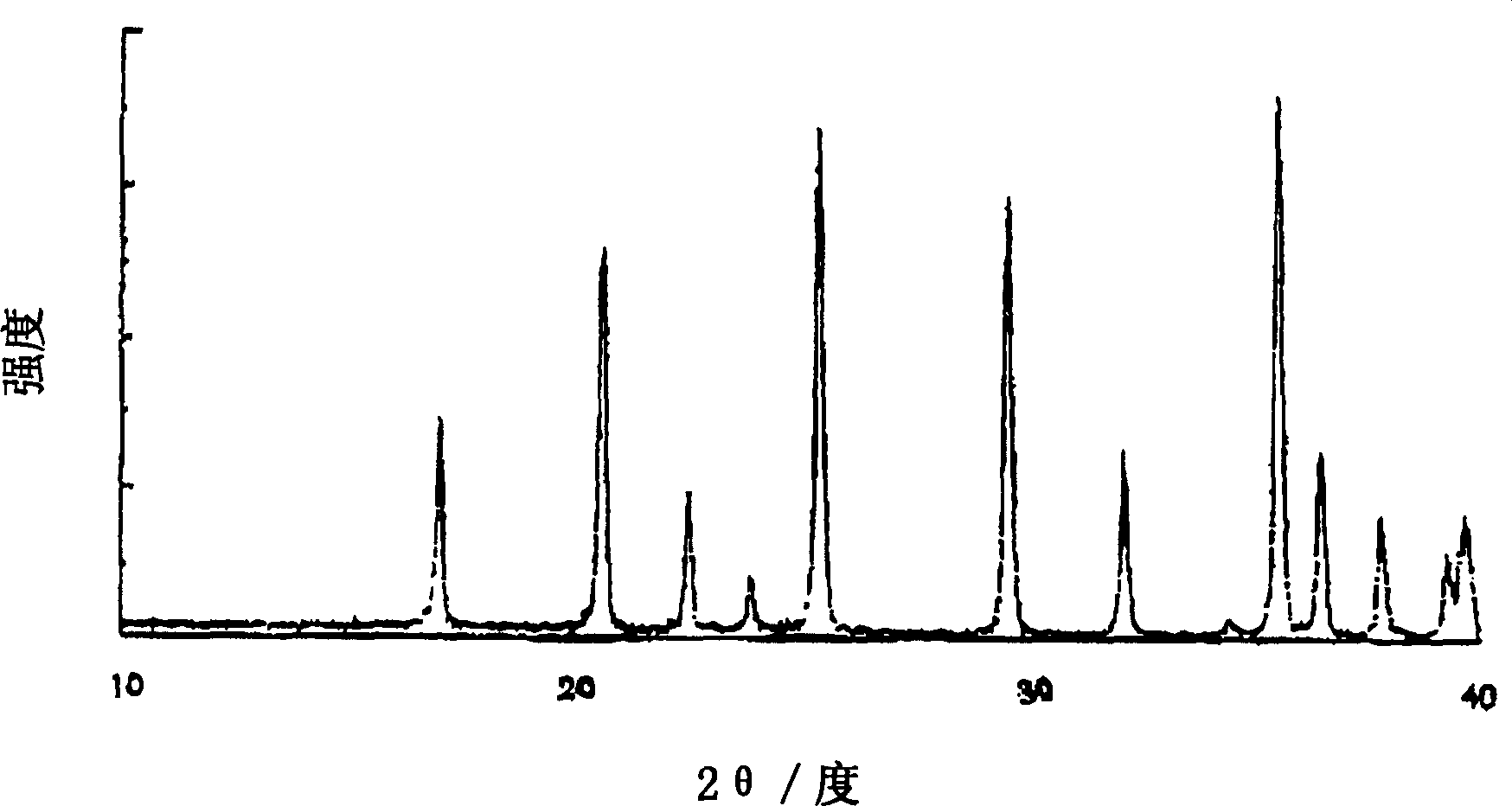

[0130] The ferrous phosphate hydrate crystallization (Fe 3 (PO 4 ) 2 ·8H 2 O), 2.4kg lithium phosphate (Li 3 PO 4 , average particle diameter 5.8 μm, manufactured by FMC Corporation) and 1 kg of highly conductive carbon black with a particle diameter of 0.05 μm (manufactured by Ketsutian Black Inta-Nashional Corporation, trade name ECP) were fully mixed. Next, the mixture is pulverized using a dry bead milling device to obtain a reaction primary product. Table 3 shows the main physical properties of the reaction precursors obtained.

[0131] In addition, put 10 g of the sample into a 50 ml measuring cylinder, fix it on the dual automatic vibration (DUAL AUTOTAP) device manufactured by "YUASA-IONICS Co., Ltd.", and after vibration 500 times, read the volume, according to the following formula Calculate the specific volume of the bead mill pulverized product.

[0132] 【Mathematical formula 2】

[0133] Specific volume (ml) = V / F

[0134] (In the formula, F represen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com