Guided wave resonance based polarization method

A guided wave resonance and polarization technology, which is applied in the field of optoelectronic communication and optical information processing, can solve the problems of limited application range, device performance degradation, performance difference, etc., and achieve the effect of reducing insertion loss, small light intensity loss, and small insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

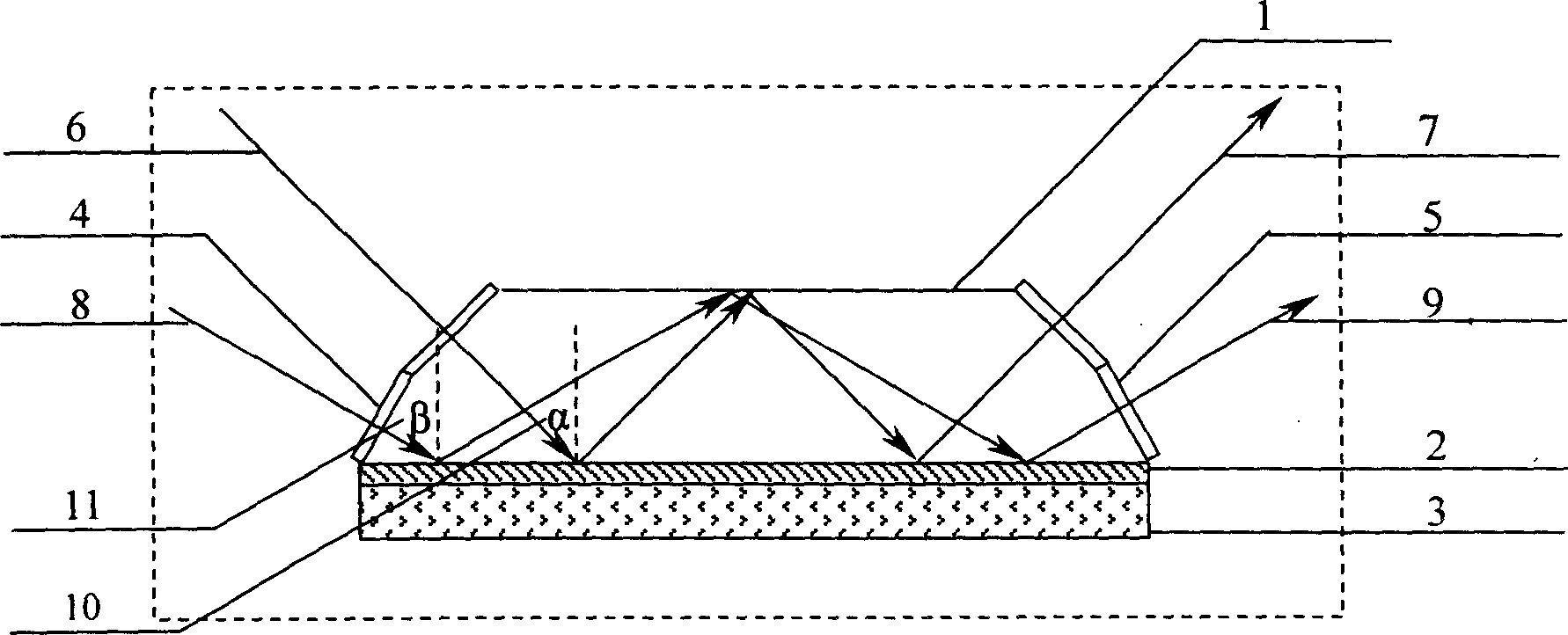

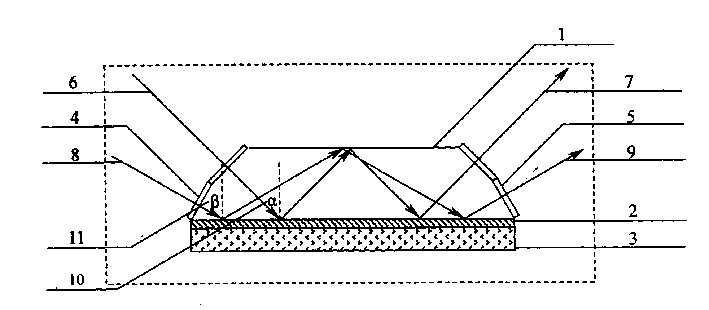

[0026] Step 1: The material of the elongated prism 1 is an elongated prism with a high refractive index (ZF6, n=1.7355). The wavelength of the incident laser is 690.0nm, and the metal film 2 on the bottom surface is made of silver (ε=-19.69+i1.24 at a wavelength of 690.0nm). The material of the dielectric thin film 3 is a polymer with a refractive index of 1.68 and a thickness of 0.45 μm. The inclination angles of the two planes on the side of the elongated prism 1 to the bottom surface are 42.6 degrees and 54.2 degrees respectively, and its height is about 1 cm. The light beam forms two reflections on its lower bottom surface; the incident angle of the incident laser beam 6 and the exit angle of the exit laser beam 7 are both 42.6 degrees, while the incident angle of the incident laser beam 8 and the exit angle of the exit laser beam 9 are both 54.2 degrees , even if they are perpendicular to the two planes on both sides of the elongated prism 1; To select P polarized light...

Embodiment 2

[0030] Step 1: The material of the elongated prism 1 is an elongated prism with a high refractive index (ordinary optical glass, n=1.5). The incident laser wavelength is 560.0nm, and the material of the metal film 2 on the bottom surface is silver (ε=-11.89+i0.83 at a wavelength of 560.0nm). The material of the dielectric thin film 3 is a polymer with a refractive index of 1.68 and a thickness of 0.9 μm. Two planes on the side of the elongated prism 1 are respectively 42.85 degrees and 51.1 degrees to the inclination of the bottom surface, its height is about 1.2 cm, the length of the upper bottom surface is 2.3 cm, and the length of the lower bottom surface is about 4.5 cm, which satisfies the two reflection conditions, so that The laser beam forms two reflections on its lower bottom surface; the incident angle of the incident laser beam 6 and the exit angle of the exit laser beam 7 are both 42.85 degrees, while the incident angle of the incident laser beam 8 and the exit ang...

Embodiment 3

[0034] Step 1: The material of the elongated prism 1 is an elongated prism with a high refractive index (ZF6, n=1.7355). The incident laser wavelength is 1550.0nm, and the material of the metal film 2 on the bottom surface is gold (ε=-117.34+i10.95 at a wavelength of 1550.0nm). The material of the dielectric thin film 3 is a polymer with a refractive index of 1.68 and a thickness of 0.9 μm. The inclination angles of the two planes on the side of the elongated prism 1 to the bottom surface are 37.0 degrees and 47.35 degrees respectively, and its height is about 0.8cm. The light beam forms three reflections on its lower bottom surface; the incident angle of the incident laser beam 6 and the exit angle of the exit laser beam 7 are all 37.0 degrees, and the incident angle of the incident laser beam 8 and the exit angle of the exit laser beam 9 are all 47.35 degrees, Even if they are respectively perpendicular to the two planes on both sides of the elongated prism 1; and a layer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com