Carburetor

A vaporizer and container technology, applied in the field of liquefied petroleum gas vaporization devices, can solve the problems of poor thermal efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

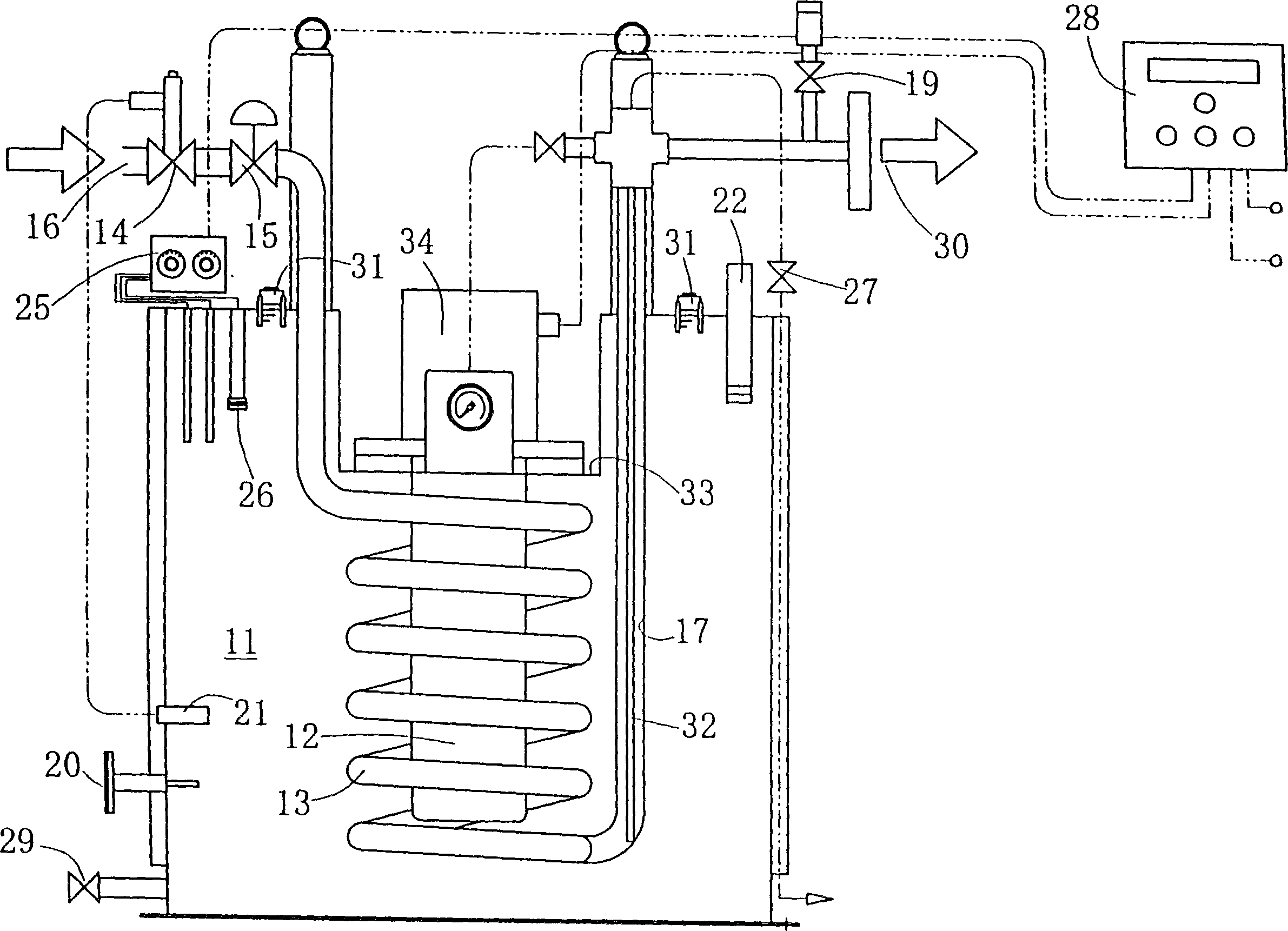

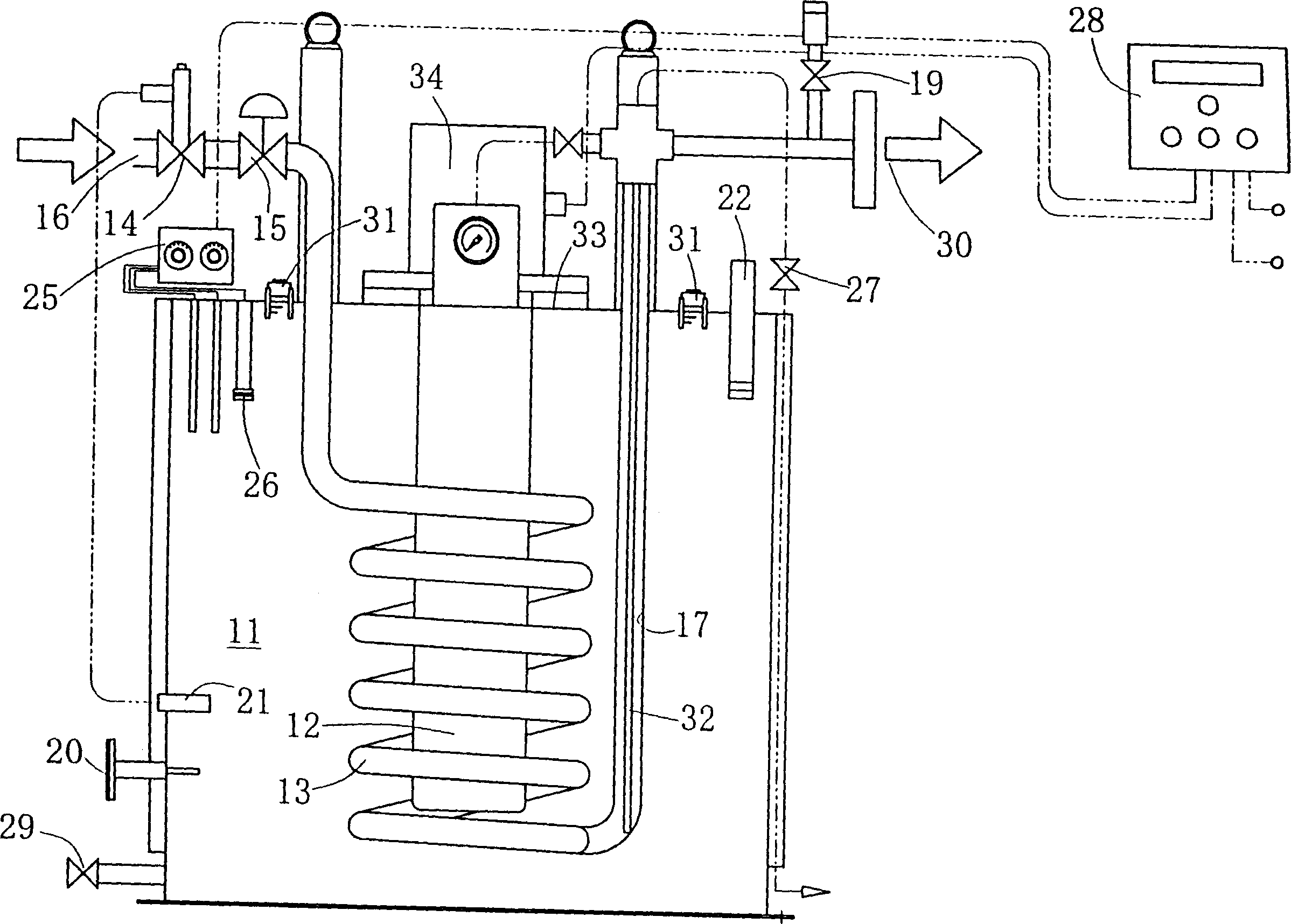

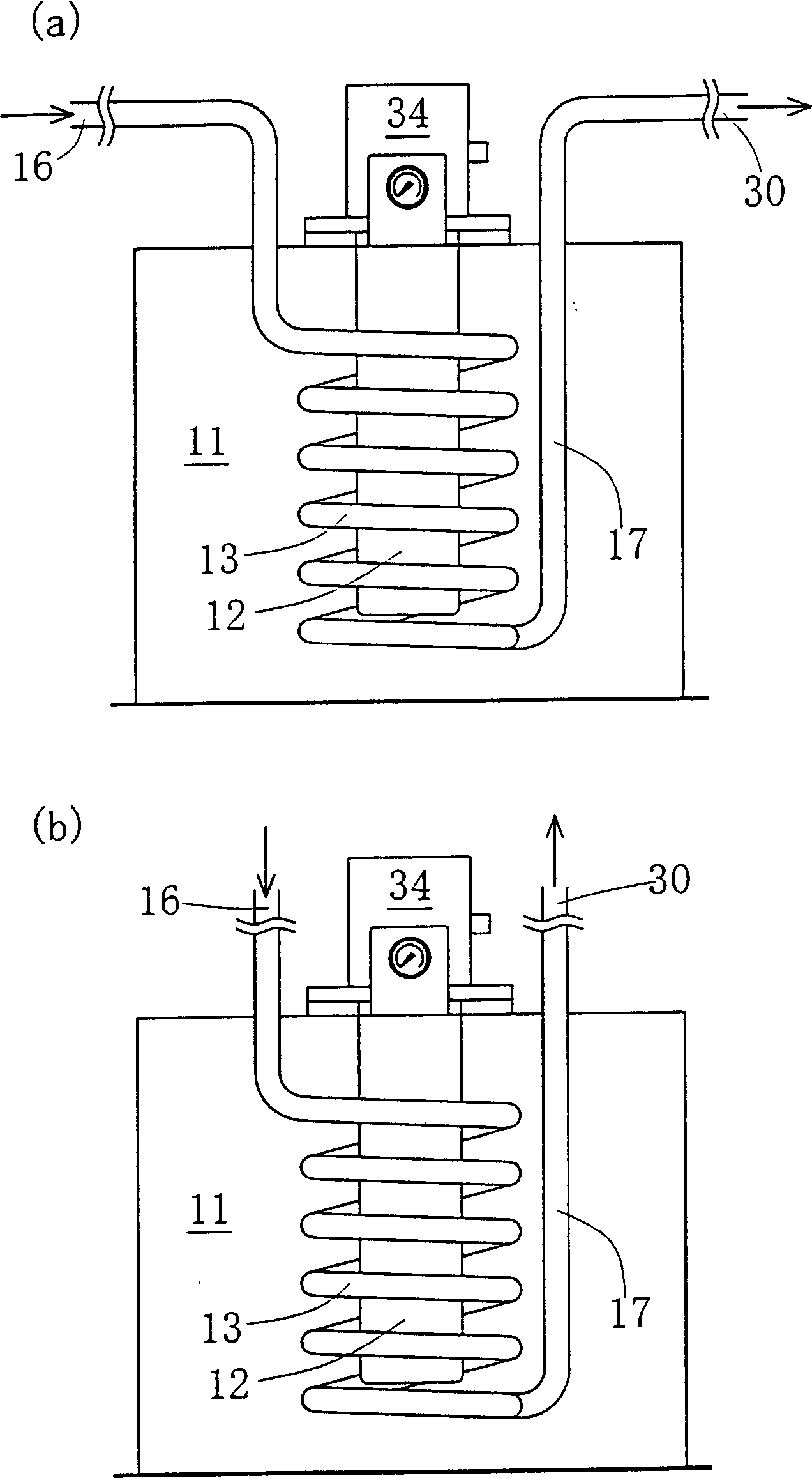

[0040] Embodiments of the present invention will be described below with reference to the drawings. The LPG imported from the air storage tank passes through the introduction pipe 16, the liquid overflow protection valve 14, and the hydraulic adjustment valve 15 to the warm water tank 11, and then continuously turns into a spiral tube 13, which is connected to the evaporation cylinder 17 near the bottom of the warm water tank 11 and passed through the extension tube. The upwardly facing safety valve 19 is connected to a consumption line 30 .

[0041] On the other hand, the heater 12 is arranged at the center of the spiral tube 13 at equal intervals from the surrounding spiral tubes 13 .

[0042] The warm water tank 11 is equipped with a thermometer 20 for warm water, a temperature sensor 21 for actuating the liquid overflow protection valve, a temperature regulator 25, a float switch 26, a gas discharge valve 31 for the warm water tank, a water level gauge 22, and a thin tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com