Fibrous filtering material for water treatment

A fiber filtration and water treatment technology, applied in the fields of suspended impurities and filter materials, can solve the problems of difficult cleaning, low retention efficiency, and large residual sludge in the filter bed, so as to improve backwashing efficiency and reduce backwashing water consumption. , The effect of high solid-liquid separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

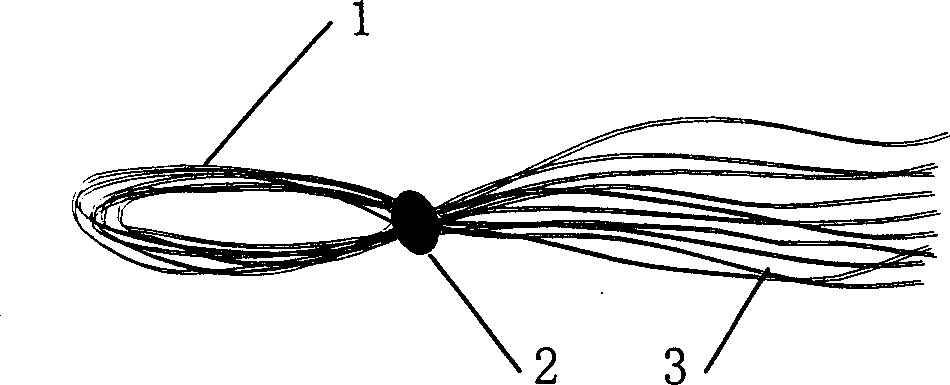

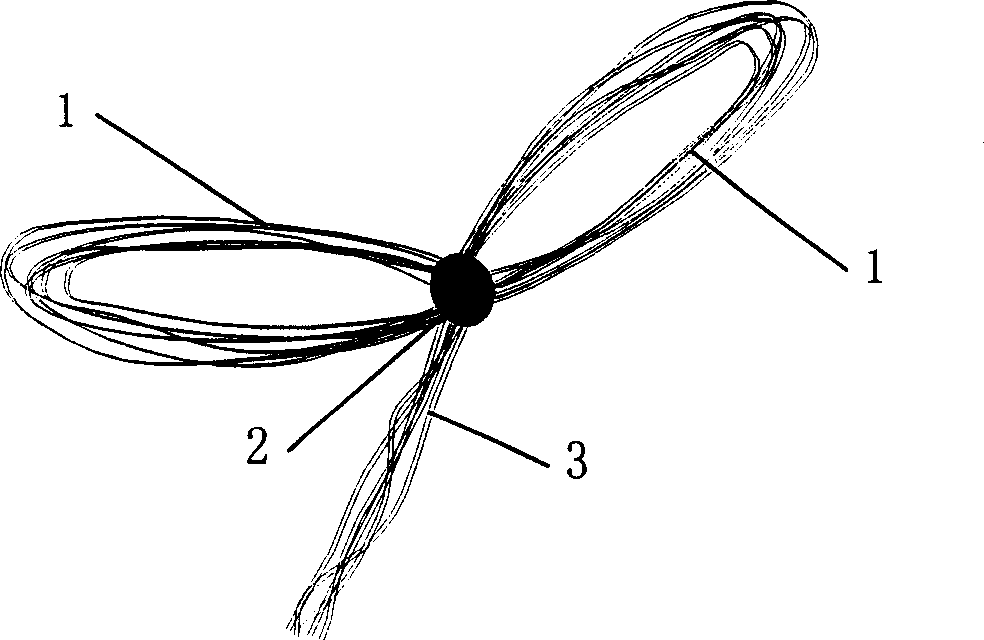

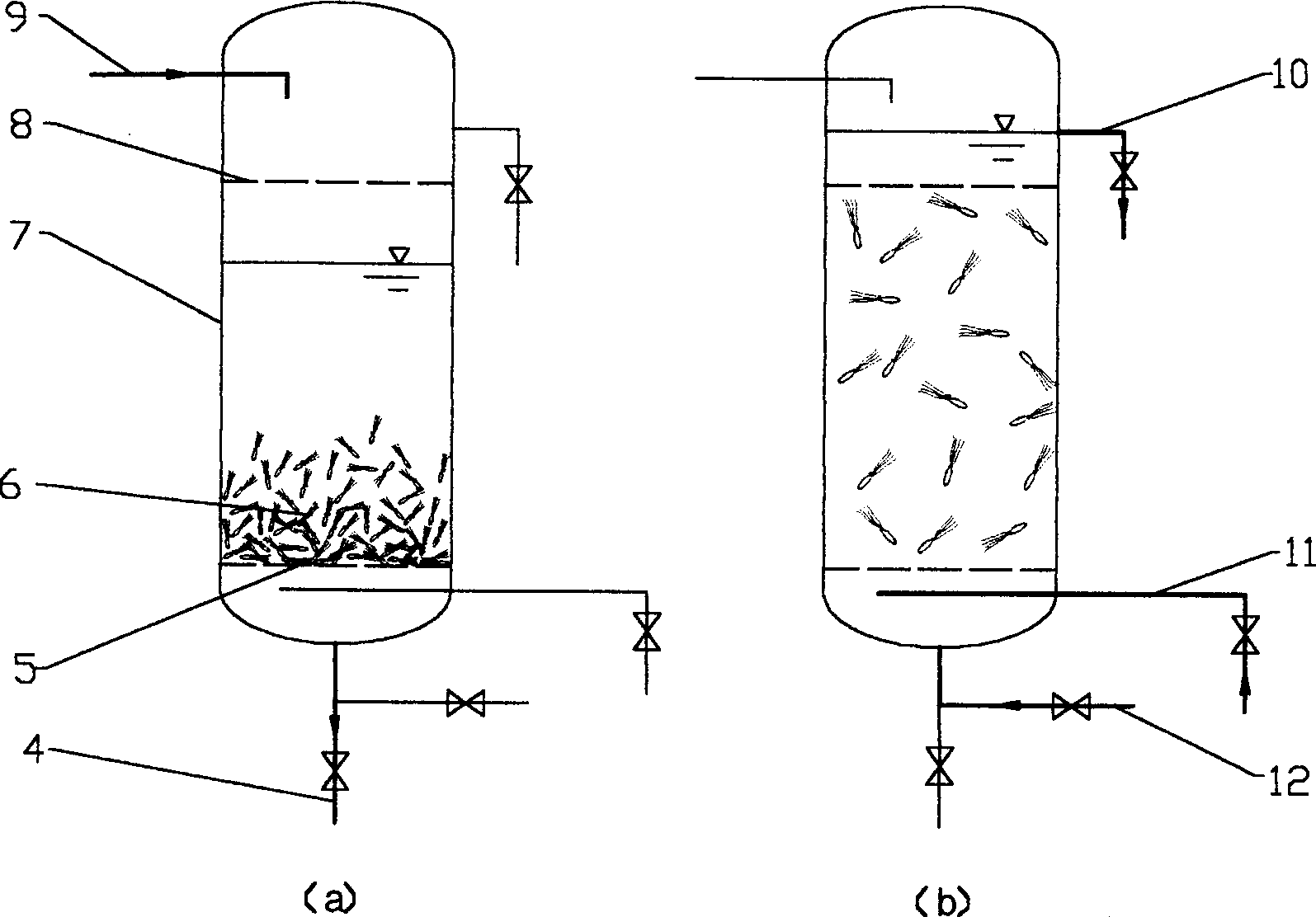

[0031]The ramie plant fibers with a monofilament diameter of 15 microns are bundled to form a filter material for a tow circle and a tail tow. The straightened length of the tow circle is 5 mm, and the length of the tail tow is 20 mm. Multiple ramie fibers form a silk bundle, and the diameter of the circumscribed circle of the bundle after bundle is 1.5 millimeters. The tow circle and tail wire are fixed in the tow section by hot pressing, and the tow section is made spherical by adding ceramic powder plastic, and the diameter of the circumscribed circle of the tow section is 2.5 mm.

[0032] Filter material

Embodiment 2

[0034] Viscose fibers with a single diameter of 10 microns and ramie fibers with a single diameter of 15 microns are mixed and bundled by 50% each to form two tow loops and tails. The straightened length of the tow circles is 40 mm, and the tails are The length of the tow is 120 mm, and the diameter of the circumscribed circle of the tow is 2 mm after a plurality of fibers are bundled. The tow ring and tail wire are fixed in the tow section by molding method, and the tow section is made of ellipsoidal porous ceramic microwave low-temperature sintering, and the diameter of the circumscribed circle of the tow section is 5 mm.

[0035] The filter size, the filling height of the filter material, and the operating conditions are the same as in Example 1, and the operating results are as follows.

[0036] Filtration rate 32 (m / h)

[0037] Influent ss 25-28 (mg / l)

[0038] Effluent ss 3-4 (mg / l)

[0039] Influent grease 15-48 (mg / l)

[0040] Effluent oil 2-4 (mg / l)

[0041] Back...

Embodiment 3

[0043] The acrylamide grafted modified polyester curly fiber with a single filament diameter of 27 microns constitutes a filter material for a tow loop and a tail. The straightened length of the tow loop is 60 mm, and the length of the tail is 150 mm. The diameter of the circumscribed circle of the tow after clustering the modified polyester fiber (polyester fiber) is 3 millimeters, and the tow ring and the tail are fixed in the tow section by injection method, and the tow section is made of rubber with metal powder added. Be spherical, and the diameter of the circumscribed circle of the tow node is 10 mm.

[0044] The filter size, the filling height of the filter material, and the operating conditions are the same as in Example 1, and the operating results are as follows.

[0045] Filtration rate 28-30 (m / h)

[0046] Influent ss 15-30 (mg / l)

[0047] Effluent ss 3-5 (mg / l)

[0048] Influent grease 80-120 (mg / l)

[0049] Effluent oil 5-12 (mg / l)

[0050] Backwash water co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com