FRP molded article and method of producing same

A fiber reinforced plastic and a production method technology, applied in the field of fiber reinforced plastic molded products and their production, can solve problems such as not being verified, and achieve the effect of low volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

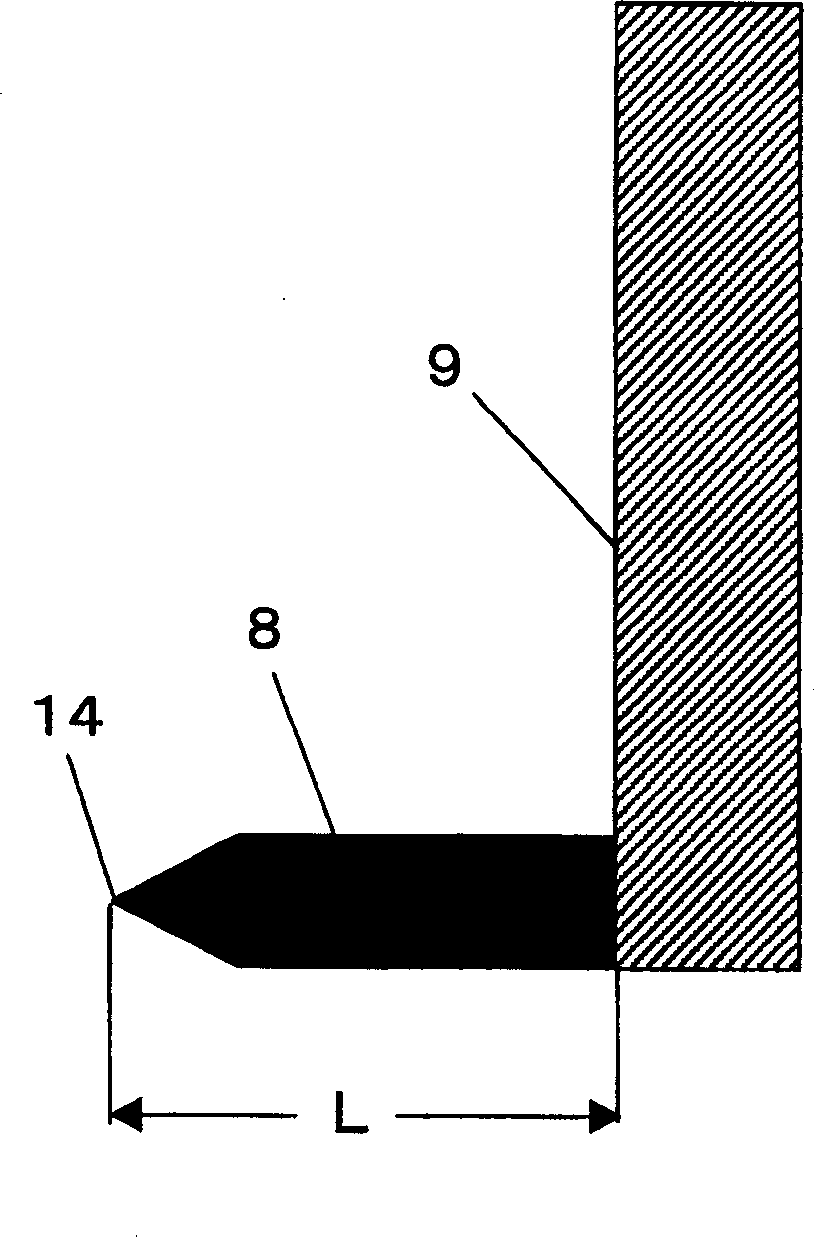

[0262] As the hot runner injection molding equipment, the SVP injection molding equipment produced by Seiki is based, and the length of the hot runner gate 8 is 125mm, and the diameter of the gate hole 14a is 1.5mm.

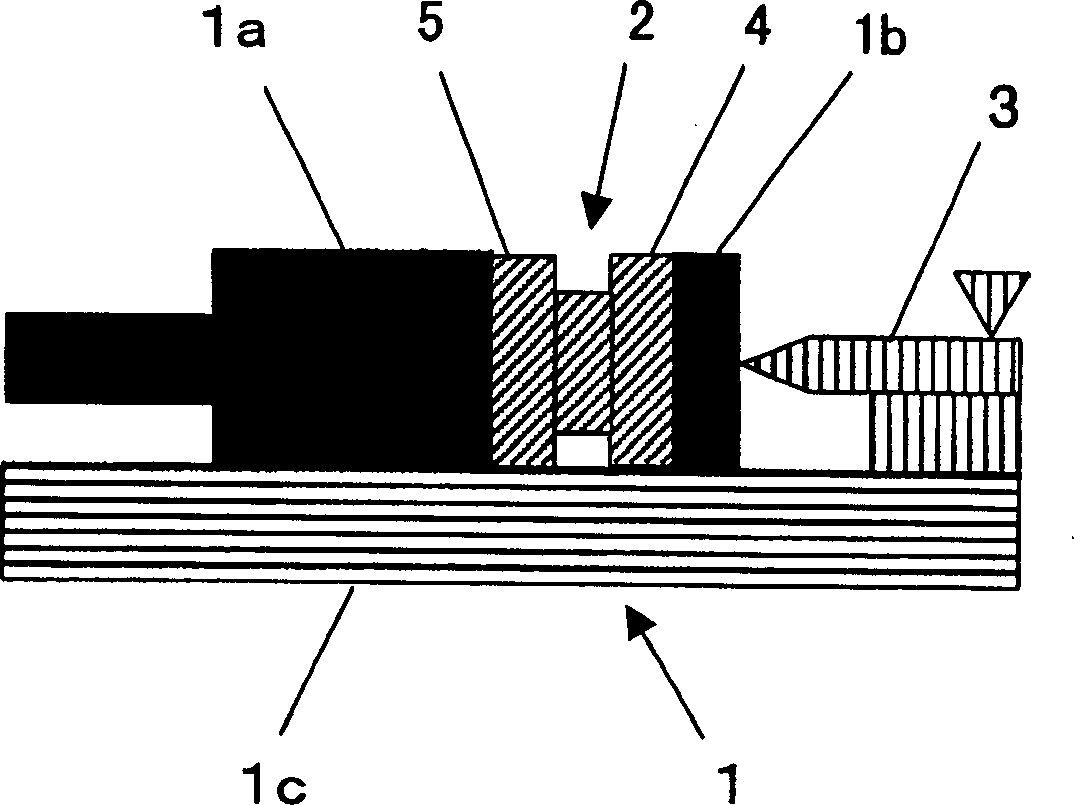

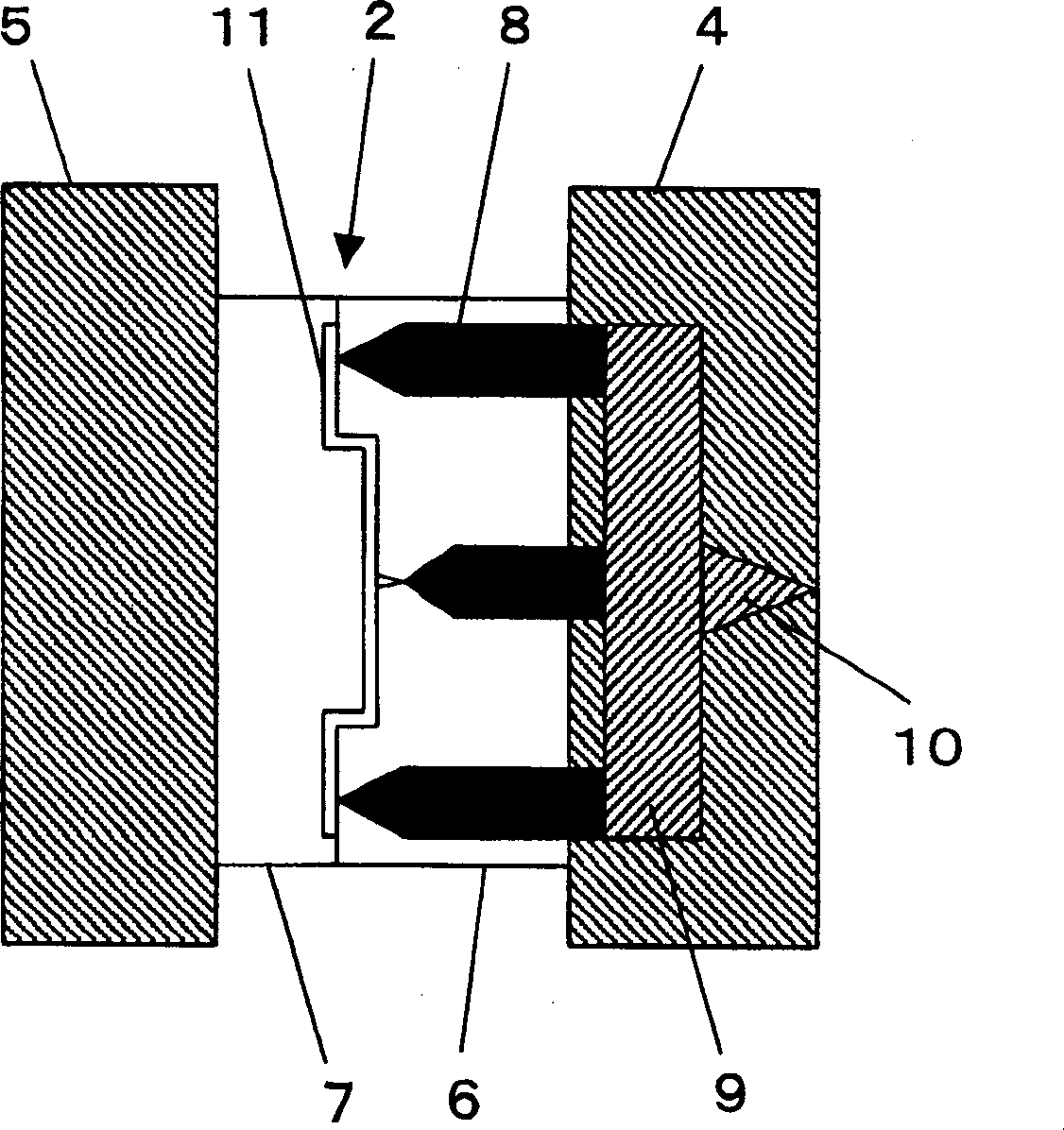

[0263] The hot runner manifold 9 has a rectangular shape with a height of 150 mm, a length of 340 mm and a width of 340 mm, and the inner resin channel has a circular cross-sectional shape with a diameter of 8 mm. The material of the hot runner manifold 9 and the hot runner nozzle 8 is SK3. exist Figure 16 The approximate vertical section of the fixed side plate 4, the movable side plate 5, the cavity 6 and the mold core 7 of the mold 2 is shown in .

[0264] On one end face of the cavity 6 , a first sprue 10 is installed, and the first sprue 10 communicates with the hot runner main pipe 9 . A plurality of hot runner nozzles 8 are provided at the end of the hot runner manifold 9 . The end of the hot runner sprue 8 is opened toward the mold hollow portion 21 t...

example 2

[0270] Mold 2 is a front gate type. exist Figure 18 The arrangement of the twelve hot runner nozzles 281 to 292 for the molded product 20 is shown in a top plan view. The mold 2 was used and the shaped article 20 was produced in the same manner as described in Example 1.

example 3

[0272] Mold 2 is a front gate type. exist Figure 19 The arrangement of the fourteen hot runner nozzles 381 to 394 for the molded product 20 is shown in a top plan view. The mold 2 was used and the shaped article 20 was produced in the same manner as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fiber length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com