Transverse double-frequency zeeman laser linearity/coaxality measuring mechanism

A technology of coaxiality measurement and dual-frequency laser, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of installation adjustment errors, affecting the consistency of measurement results, and many laser head parts, etc., to achieve the elimination of nonlinearity error, beneficial to phase measurement, and the effect of simple instrument structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

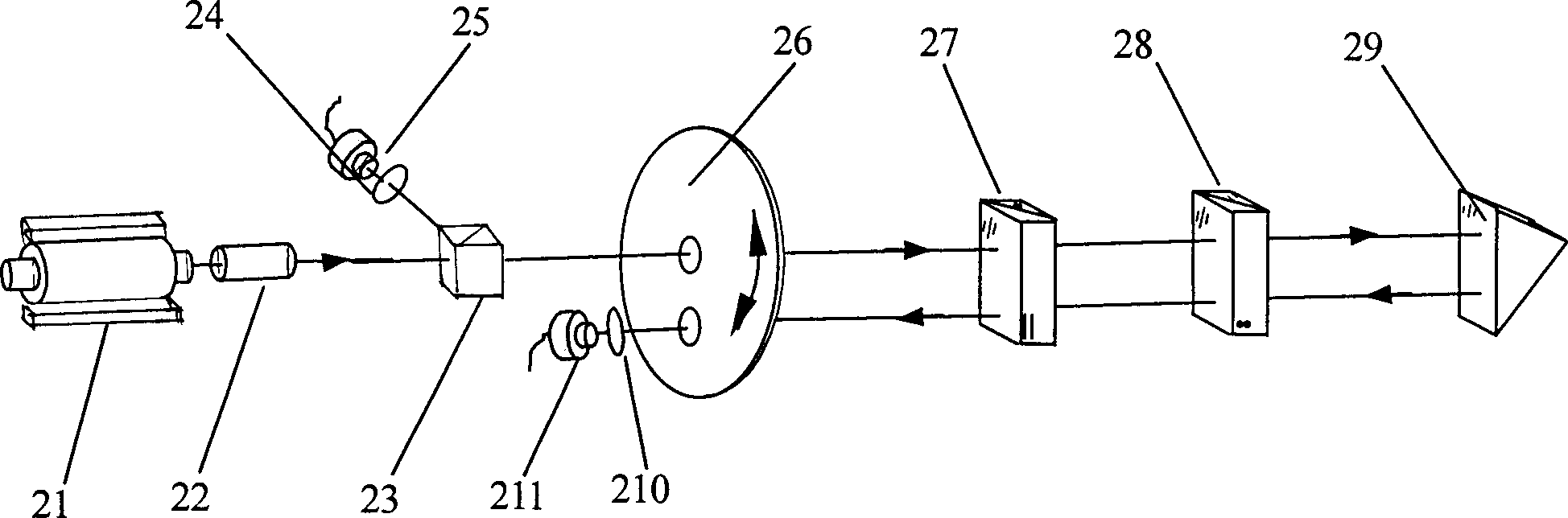

[0044] Embodiment 1 is to measure straightness. Its structure is as figure 2 As shown, among them, the SJD-5T transverse Zeeman dual-frequency laser 21 is used, and the frequency stabilization accuracy is 10 -7 , the frequency difference is 243.6K, the frequency difference stability is 0.5KHz / 10hour, the frequency response ranges of the two photoelectric receivers 25 and 211 are both 50-500KHz, and the wedge angles of the two Wollaston prisms 27 and 28 are both 0.28 Spend. Put the laser head on one end of the guide rail, place the rectangular prism 29 and the second Wollaston prism 28 on the other end of the guide rail, and place the first Wollaston prism 27 on a platform that can move along the guide rail. The signal processing adopts the Danish 2977 phase meter. The output end of the phase meter is connected with the computer, its input end is connected with the output end of the signal amplifying circuit, and the output ends of the two photoelectric receivers 25 and 211...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com