Gearing chain ring and its application in speed variator

A transmission chain, continuously variable transmission technology, applied in the transmission chain, transmission, belt/chain/gear and other directions, can solve the problems of complex structure, unpopularity, poor efficacy, etc., and achieve the effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

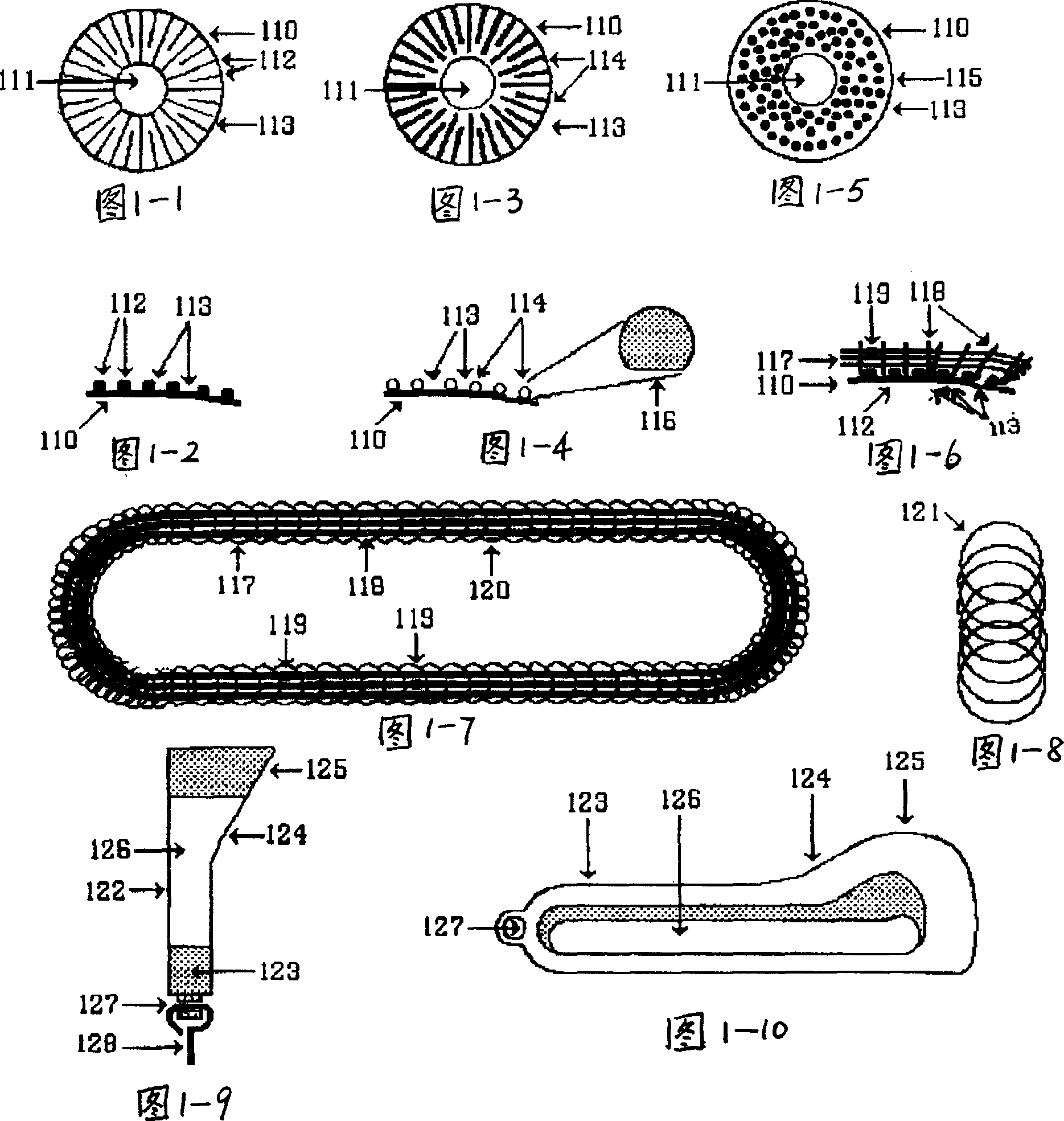

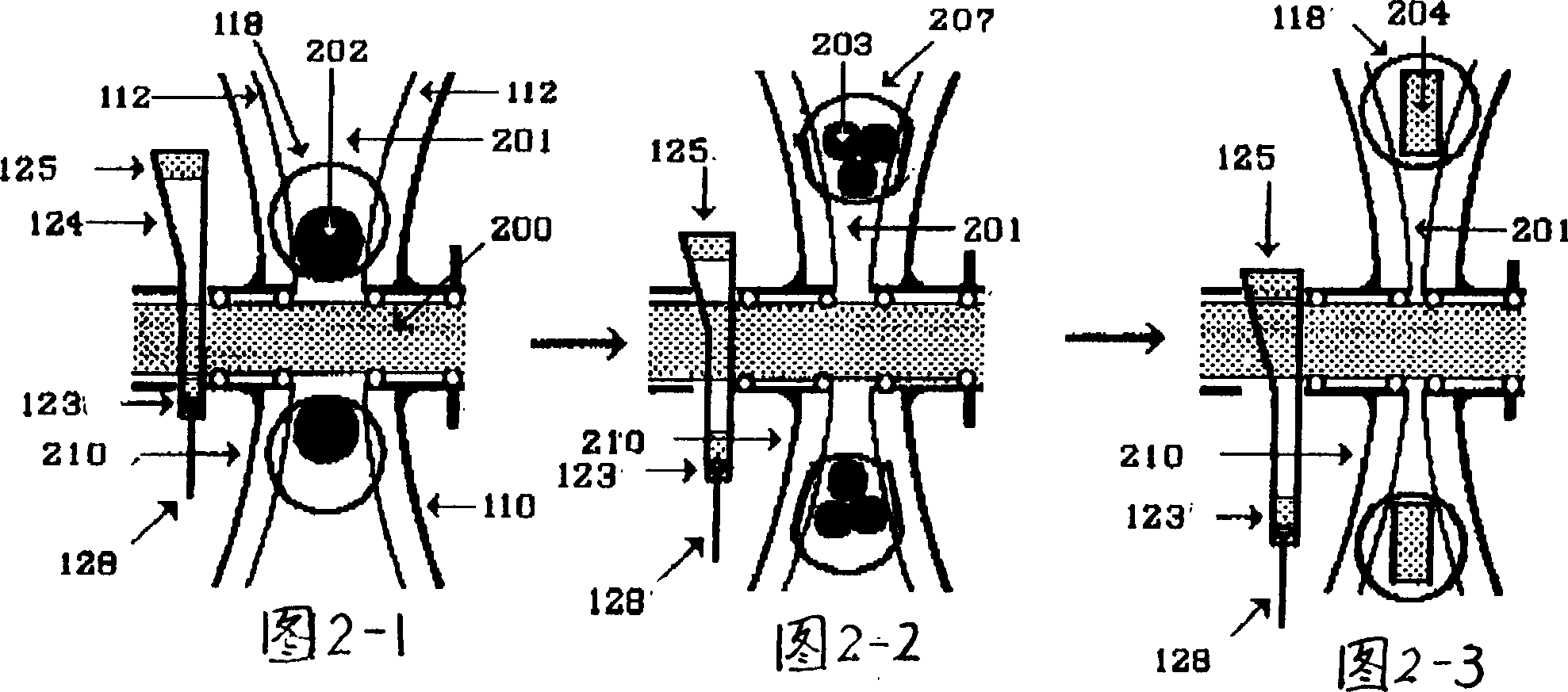

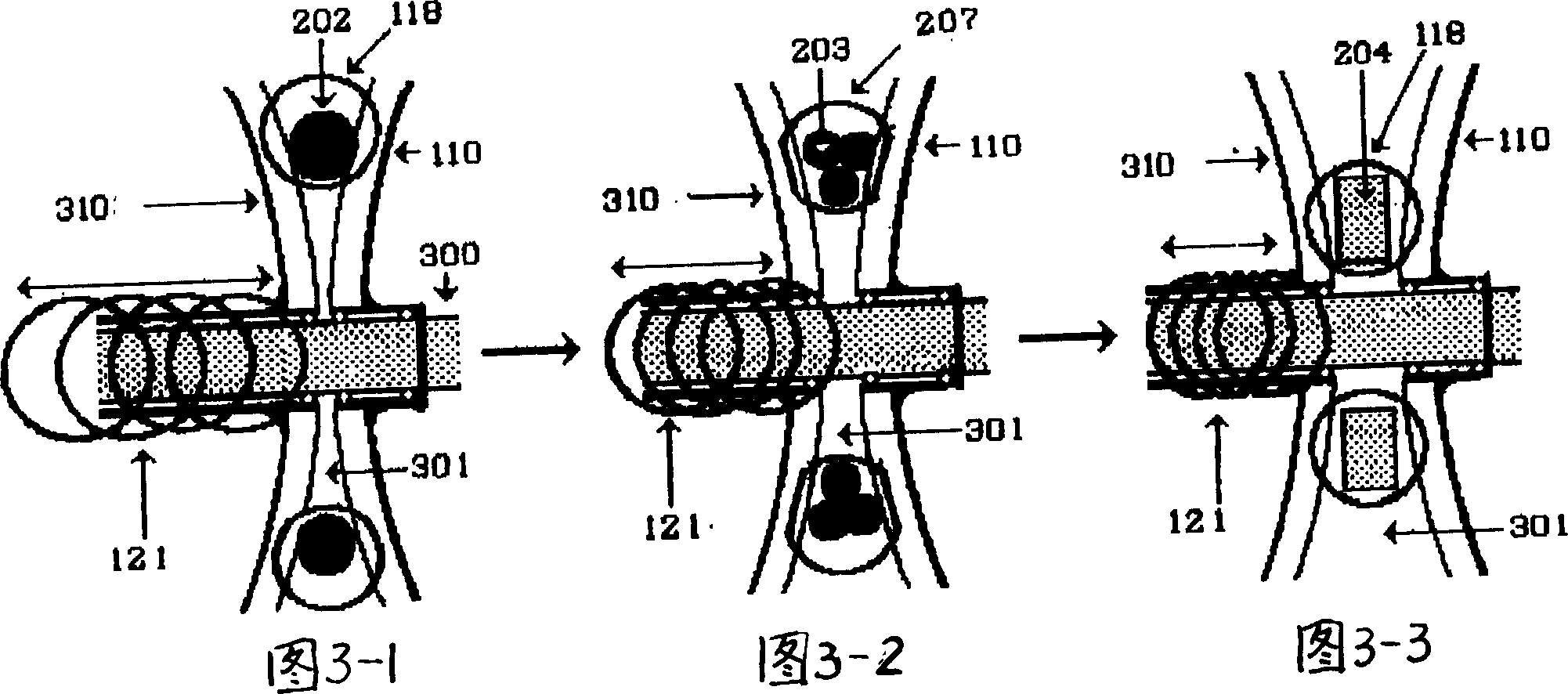

[0035] refer to figure 1 -7, with the usual cable-shaped power transmission part steel cable 117, use endurance rubber rope, iron chain 204 (referring to Figure 3-2 , Figure 3-3 As shown) or steel ball strings, the effect is the same, it penetrates into the whole spring steel wire ring 118 of the ring-shaped engaging part, and the two ends of each are welded into a ring at the welding points 119 and 120 to form a special spring-shaped ring-shaped steel cable chain ring , becoming a transmission chain link. The ring that steel cable 117, iron chain 204 or steel ball string, endurance glue rope constitute can stop spring from elongating. At least one cable-shaped force transmission member (see diagram 2-1 and Figure 3-1 202 shown), also can be two or more (see Figure 2-2 and Figure 3-2 Shown 203), increase tensile strength, can hold in the spring steel wire loop 118 as a limit; Can select any one or several and use in steel cable, iron chain, steel ball string chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com