Polyiner/laminate inorganic nano composite material and its milling shearing preparation method

A technology of nanocomposite materials and composite materials, which is applied in the field of polymer/layered inorganic nanocomposite materials and their grinding disk shearing preparation, can solve the problems of small interlayer spacing and difficult intercalation and compounding, and achieve high selectivity and adaptability wide-ranging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is specifically described below by way of examples. It is necessary to point out that the following examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention. Those skilled in the art can make some non-essential improvements and improvements to the present invention according to the above-mentioned content of the present invention. Adjustment.

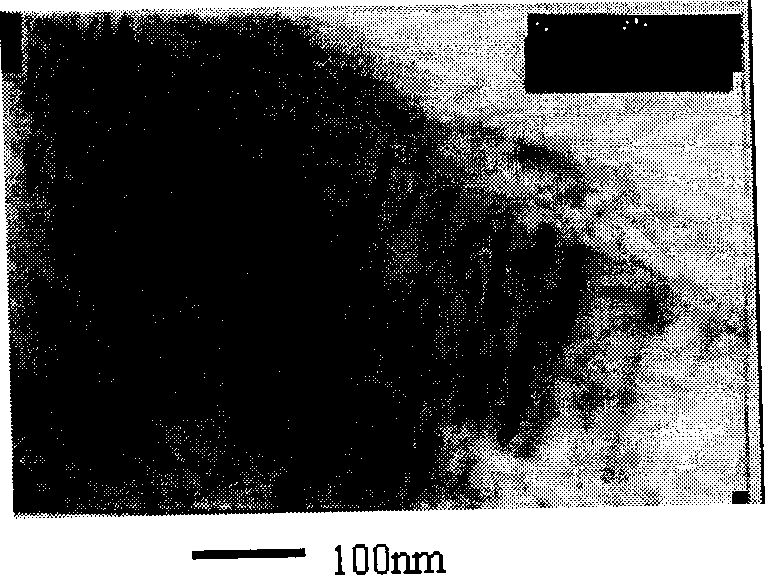

[0043] 1. PP / expanded graphite conductive nano-composite material: Firstly, 80 kg of polypropylene (F401) with a particle size of 2 to 5 mm is added to the opened mill-type mechanochemical reactor through the feeding port, and after 7 times of grinding, a coarser polypropylene is obtained Powder, continue to grind 25 times with 250 times expanded graphite 5kg treated with sodium oleate to obtain PP / expanded graphite composite powder, then mix with polypropylene (brand 4220) 15kg through double-drum mastic refining ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com