Two dimension moving three dimension rotating virtual shaft machine tool

A virtual axis machine tool and three-dimensional rotation technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that are not suitable for large-scale processing, complex curved surfaces, difficult large-inclination machining CNC programming, and small working space. Achieve good structural shock resistance and cutting stability, realize large inclination angle machining, and reduce machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

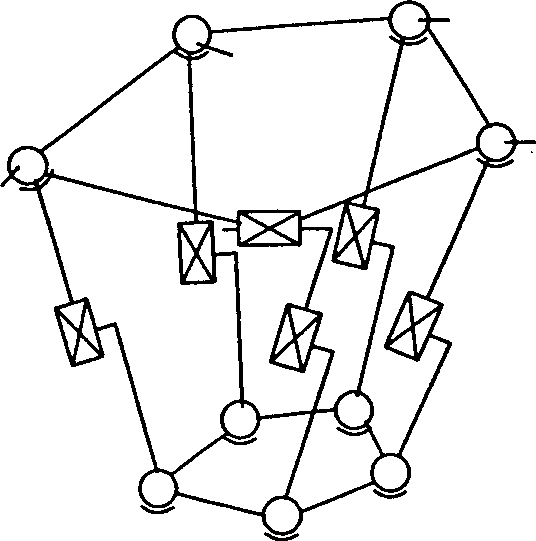

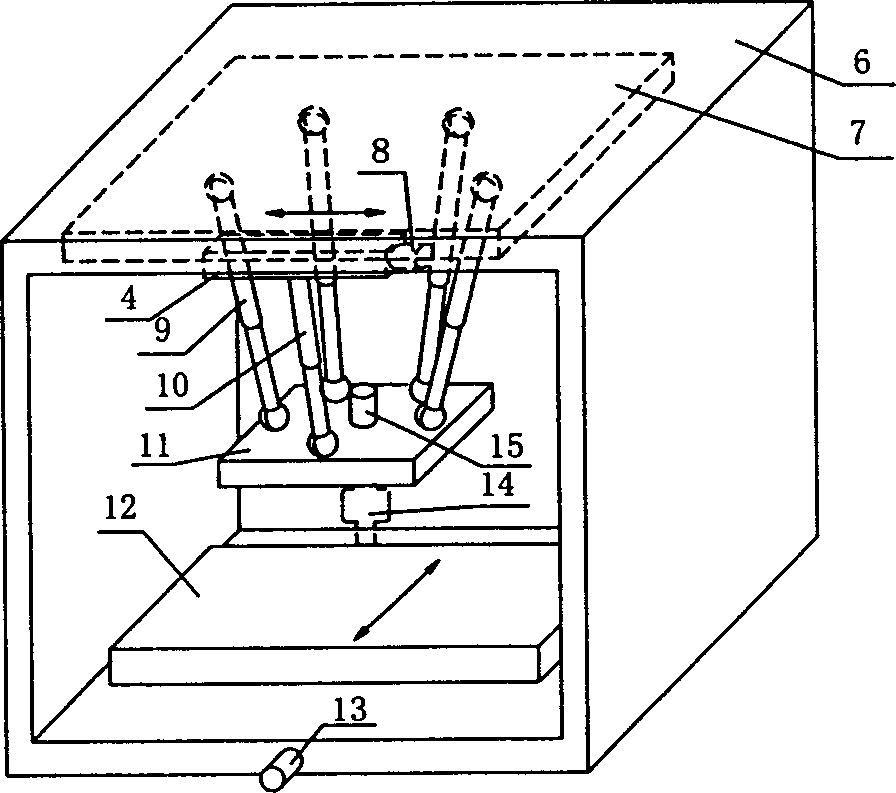

[0039] The principle of embodiment 1 is attached figure 1 As shown, the overall structure is as figure 2 shown. The virtual axis machine tool of this embodiment consists of a frame 6, a fixed platform 7 fixed on the frame, a moving platform 11 on which cutting tools are installed, a worktable 12 that can drive the workpiece to move along the Y direction, and two ends connected to the fixed platform respectively. The platform is composed of 5 connecting legs of the moving platform. Five connecting legs form a space parallel closed chain structure with the moving platform and the fixed platform. Wherein the connecting leg 10 is designed with two moving pairs, one of which is the outer moving pair 4, which is driven by a servo motor 8, and is connected with the fixed platform 7 through the components of the moving pair. Under the action of the external moving pair 4, the connecting leg can perform translational and telescopic movements along the X direction. Another moving p...

Embodiment 2

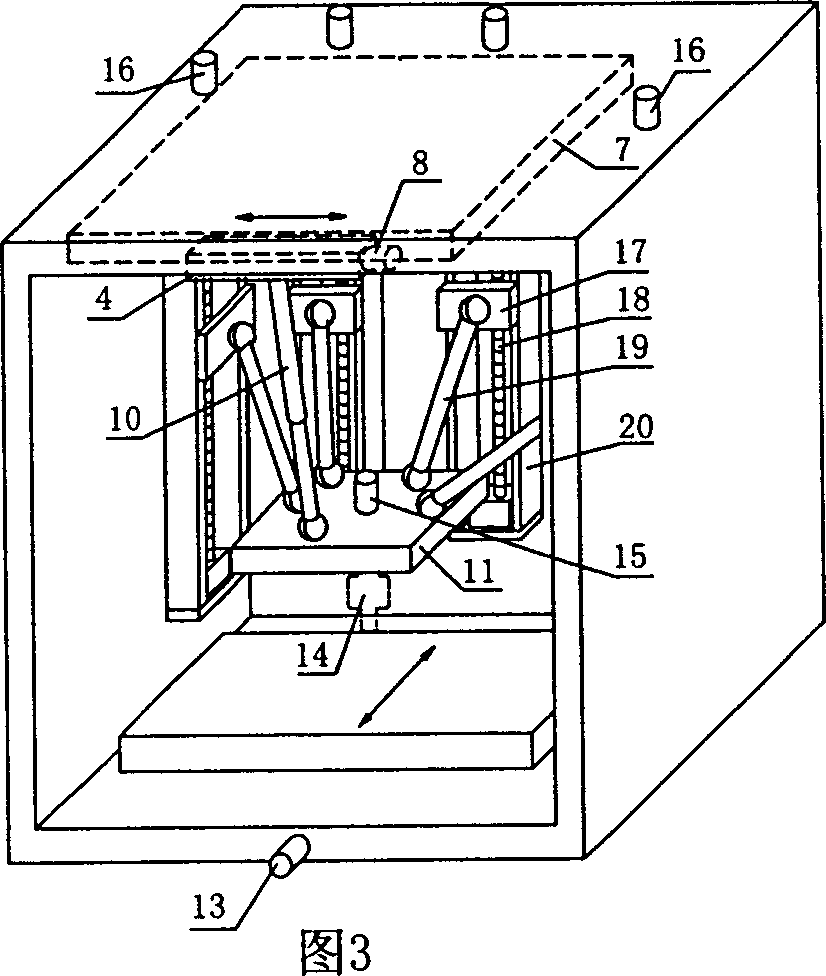

[0044] The overall structure of the virtual axis machine tool of the present embodiment is as shown in accompanying drawing 3, and its overall structure and the structure of a connecting leg 10 that contains two moving pairs are all the same as in Embodiment 1, and the difference is that a moving pair is designed 4 legs with the same structure, the structural legs are all composed of fixed length rods 19 and an outer moving pair, the outer moving pair is composed of a guide rail 20 arranged on the frame 6, a ball screw 18 and is configured with the guide rail and the ball screw The ball nut slider 17 constitutes, and the slider 17 can slide up and down along the guide rail under the drive of the servo motor 16 and the ball screw 18. One end of the fixed-length rod 19 is connected with the slide block 17 through a Hooke hinge, and the other end is connected with the moving platform 11 through a spherical hinge. This embodiment also enables the cutting tool on the moving platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com