Mouth reducing maching for packaging steel bucket

A technology of necking and steel barrels, which is applied in the direction of tanks/barrels/barrels, etc., can solve the problems of large equipment occupation, slow cam feed speed, poor appearance quality, etc., to achieve increased speed, smooth appearance, saving production space and The effect of the cost of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

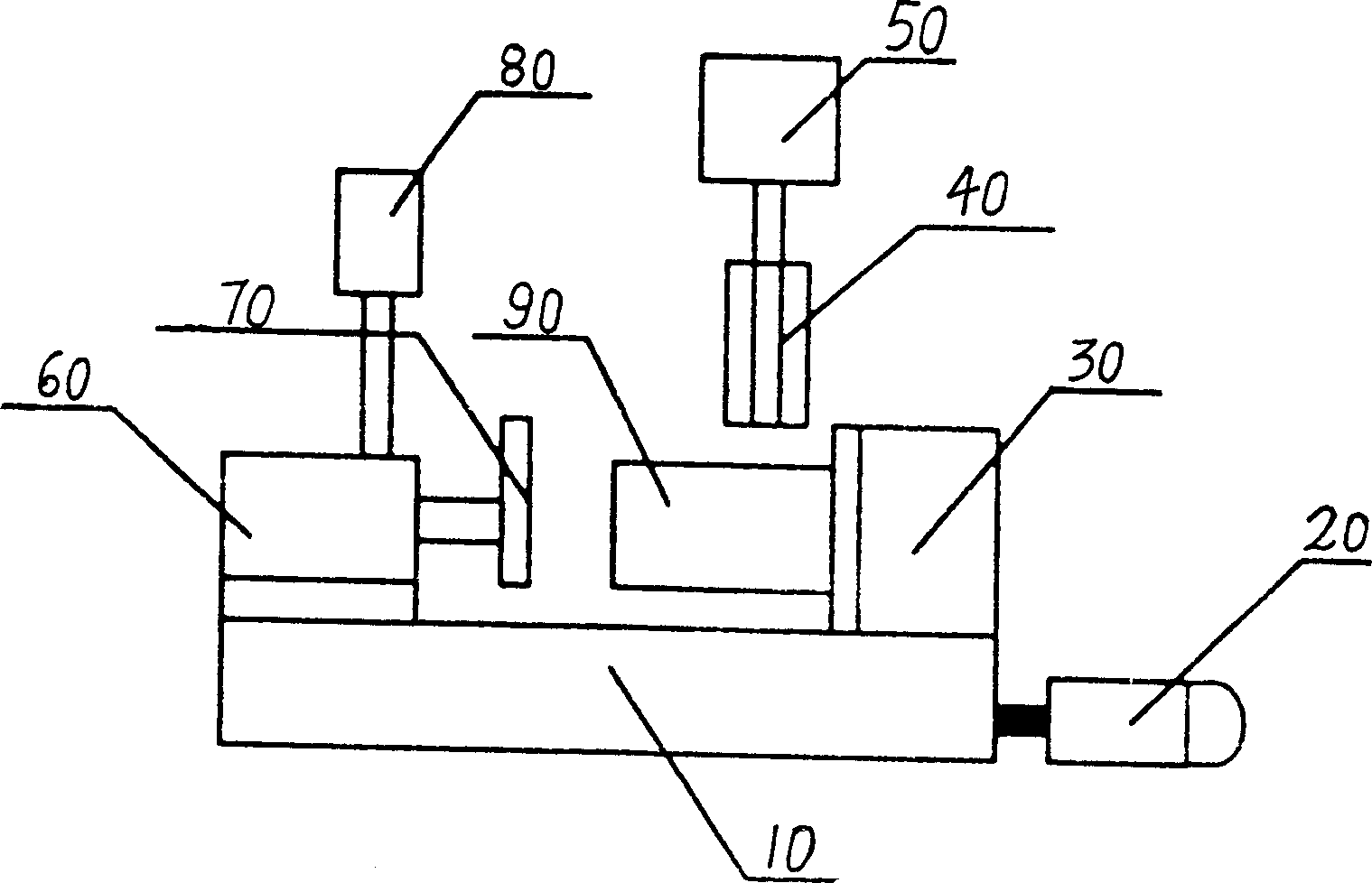

[0013] See attached image 3 , 4 , the present invention includes a fuselage 10, a motor 20, a reduction box 30, forming rollers 40, a top tightening cylinder 60, a top tightening disc 70, and a molding die 90. The output shaft of the motor 20 is connected to the forming die 90 after the reduction box 30, and the clamping disc 70 is connected to the clamping cylinder 60; the feed cylinder 50 that controls the advance and retreat of the forming roller 40 is connected to the forming roller 40; the PLC control part that controls the action of the necking machine 80 is also connected on the fuselage 10; the rib rolling mold 901 and the flanging mold 902 of the forming die 90 are sleeved on the output shaft 301 of the reduction box 30, and the elastic elements between the rib rolling mold 901 and the flanging mold 902 903 is socketed with the output shaft 301 through the inner lining 905, and a shrinking die 904 is set on the outer circle of the elastic element 903; Rings 9011, 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com