Composite fiber material, molded packing material with the fiber material and its use

A fiber composite material and packaging material technology, applied in the field of molding packaging materials, can solve the problems of poor severe impact strength and large weight, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

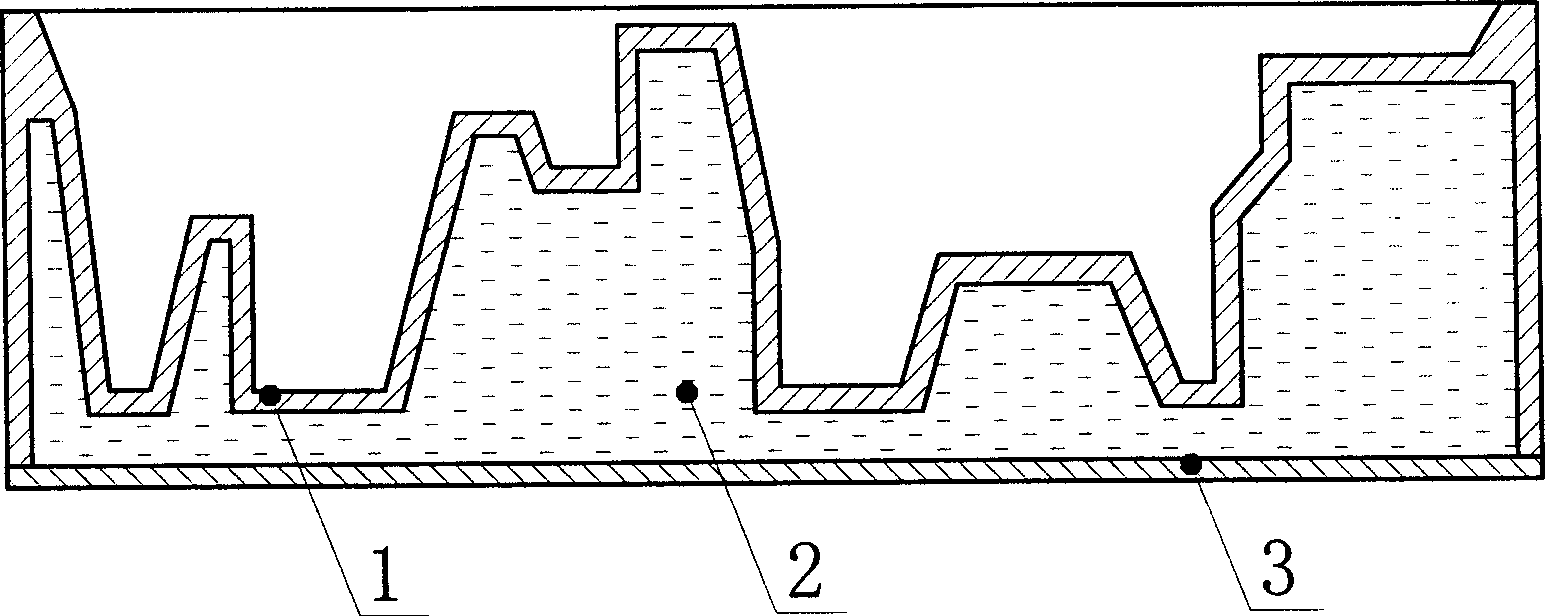

[0024] An instrument packaging template such as figure 1 As shown, the shape is 50cm long, 50cm wide, and 10cm high. figure 1 The structure shown is made, the shell layer 1 is made of white pulp and fiber composite molded parts on the outer surface; the fiber composite material fills the solid layer 2, the ratio of thick and thin fibers is 1:2, the adhesive accounts for 3% of the total weight of the material, and the thick The fiber length is 5-15mm, the fine fiber particles are 20-30 mesh, and the thickness varies according to the shape of the product; the fiber composite flat panel covering layer 3 is gray-bottomed white panel paper, and is bonded with the shell layer 1 to form an integral structure.

Embodiment 2

[0026] An instrument packaging template such as figure 1 As shown, the shape is 50cm long, 50cm wide, and 10cm high. figure 1 The structure shown is made, the shell layer 1 is made of white pulp and fiber composite molded parts on the outer surface; the fiber composite material fills the solid layer 2, the ratio of thick and thin fibers is 4:1, the adhesive accounts for 6% of the total weight of the material, and the thick The fiber length is 10-20mm, the fine fiber particles are 30-40 mesh, and the thickness varies according to the shape of the product; the fiber composite flat panel covering layer 3 is gray-bottomed white panel paper, and is bonded with the shell layer 1 to form an integral structure.

Embodiment 3

[0028] An instrument packaging template such as figure 1 As shown, the shape is 50cm long, 50cm wide, and 10cm high. figure 1 The structure shown is made, the shell layer 1 is made of white pulp and fiber composite molded parts on the outer surface; the fiber composite material fills the solid layer 2, the ratio of thick and thin fibers is 2:1, the adhesive accounts for 10% of the total weight of the material, and the thick The fiber length is 15-25mm, the fine fiber particles are 40-50 mesh, and the thickness varies according to the shape of the product; the fiber composite flat panel covering layer 3 is gray bottom white panel paper. And bonded with the shell layer 1 to form an integral structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com