Flowing mechanical treater for page-type printing material

A technology of printing materials and flowing machinery, applied in general parts of printing machinery, printing presses, thin material processing, etc., to achieve the effect of simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

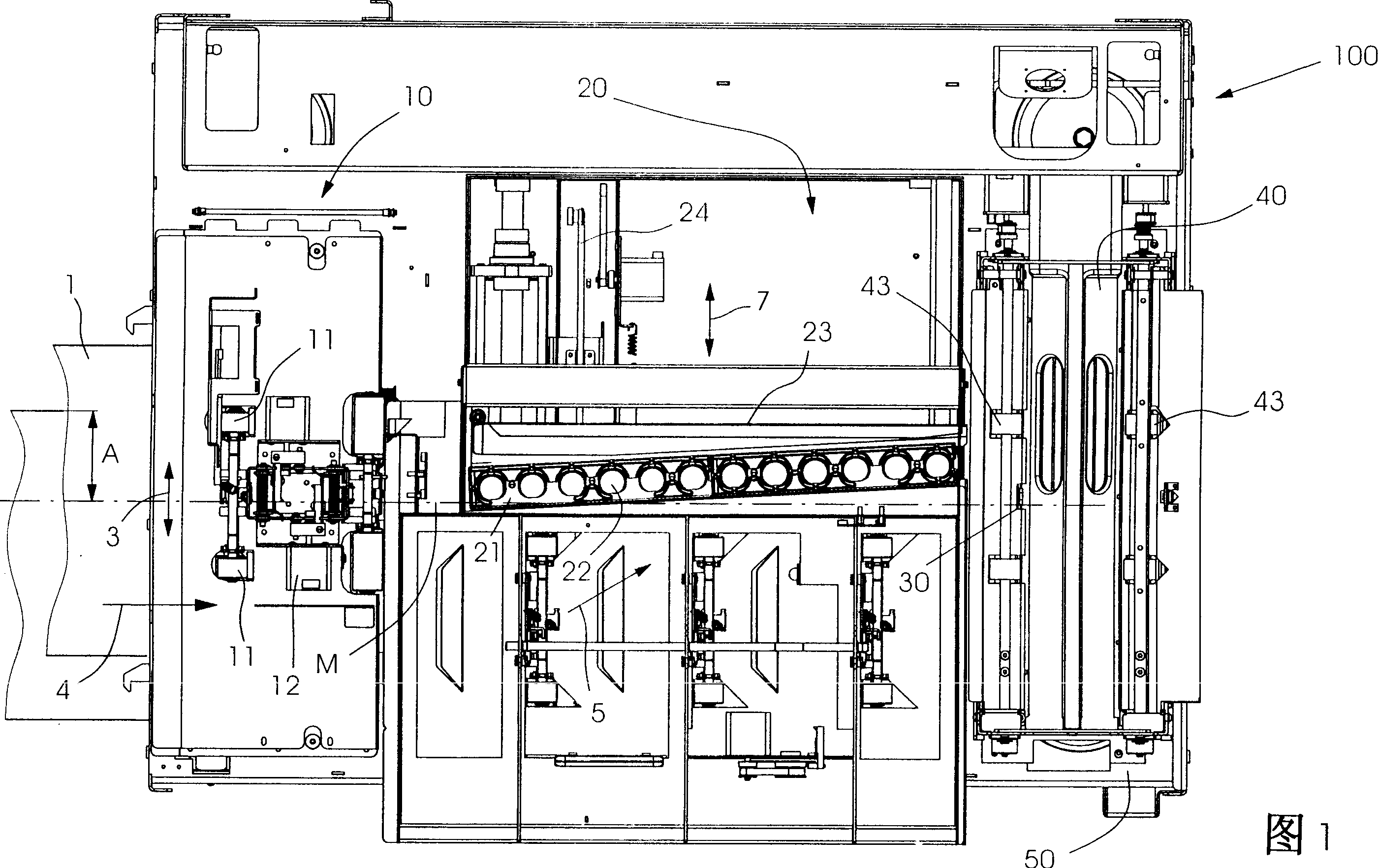

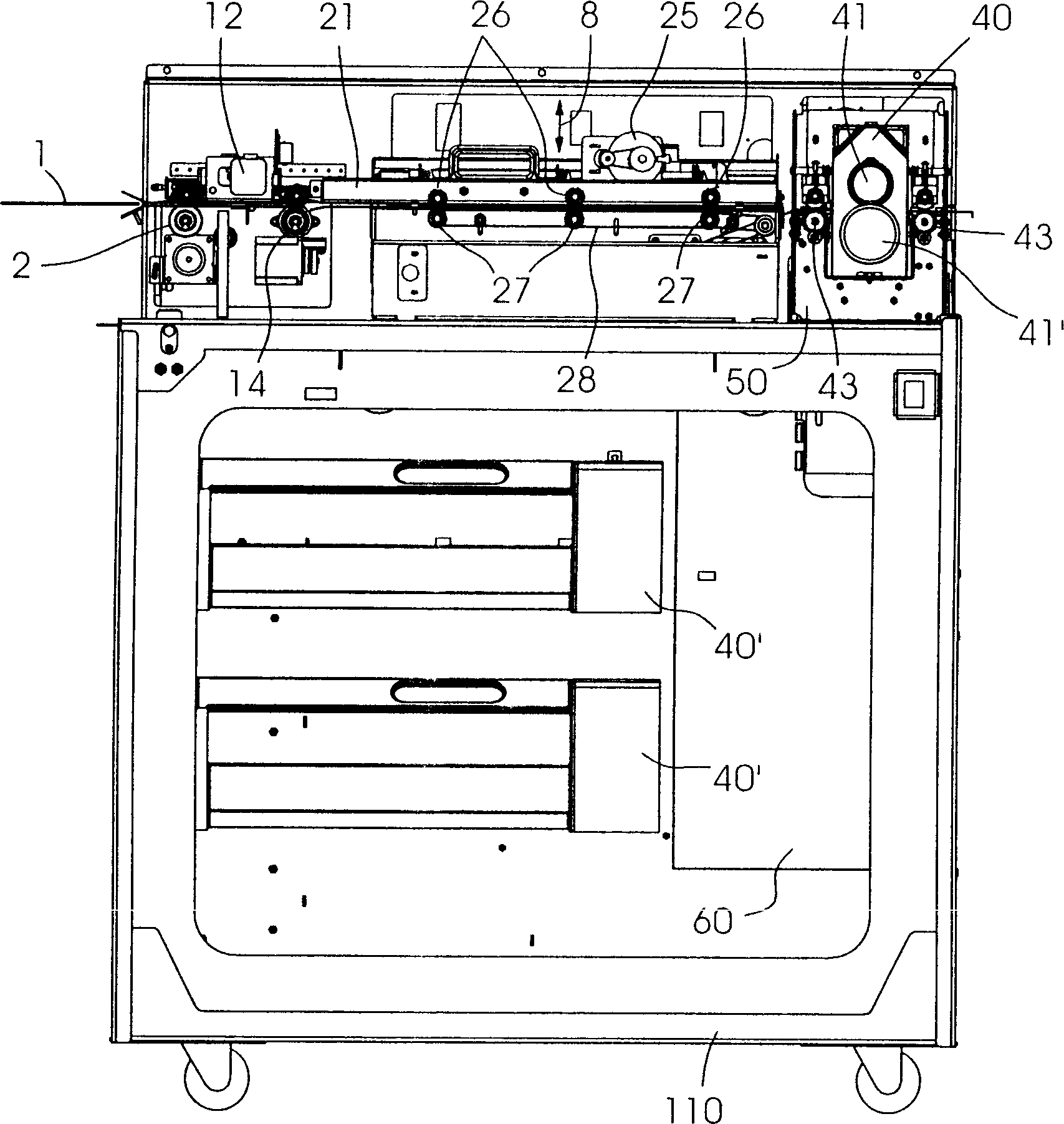

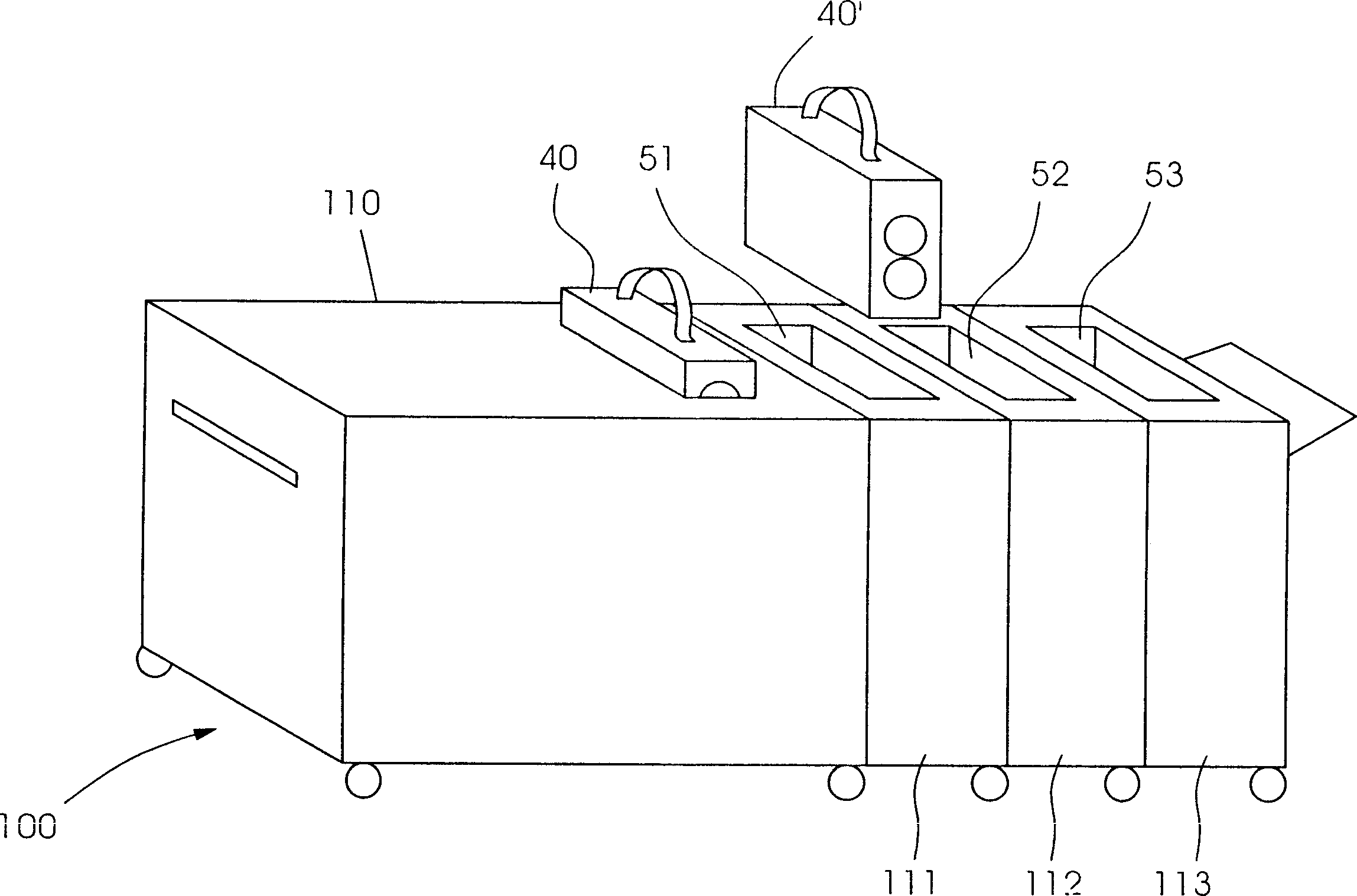

[0053] FIG. 1 shows a schematic plan view of the overall structure of a preferred embodiment of a device 100 according to the invention, and the description here is limited to the components according to the invention. Furthermore, generally known drives and / or guides and cams and electrical circuits for operating the device are only shown schematically or described in general form.

[0054] Figure 1 and figure 2 As shown in , the sheet-like printing material enters the device according to the invention in the vicinity of a transport roller pair 2, and wherein the side edge of the sheet-like printing material 1 passes through the sheet-like printing material 1 along the direction of movement indicated by the reference number 4 according to The centerline M of the transport path of the device 100 of the present invention has a distance A. As shown in FIG. In a prepositioning device 10 the distance A is determined by means of an edge sensor (not shown) and transmitted to a logi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com