Hollow yarn membrane module, hollow yarn membrane module unit, and method for producing hollow yarn membrane modules

A technology of fiber membranes and fiber membrane bundles, applied in the field of hollow fiber membrane module devices, can solve the problems that the filtration performance of hollow fiber membrane modules cannot be restored to the expected level, and achieve stable filtration performance, excellent water resistance, alkali resistance and non-toxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

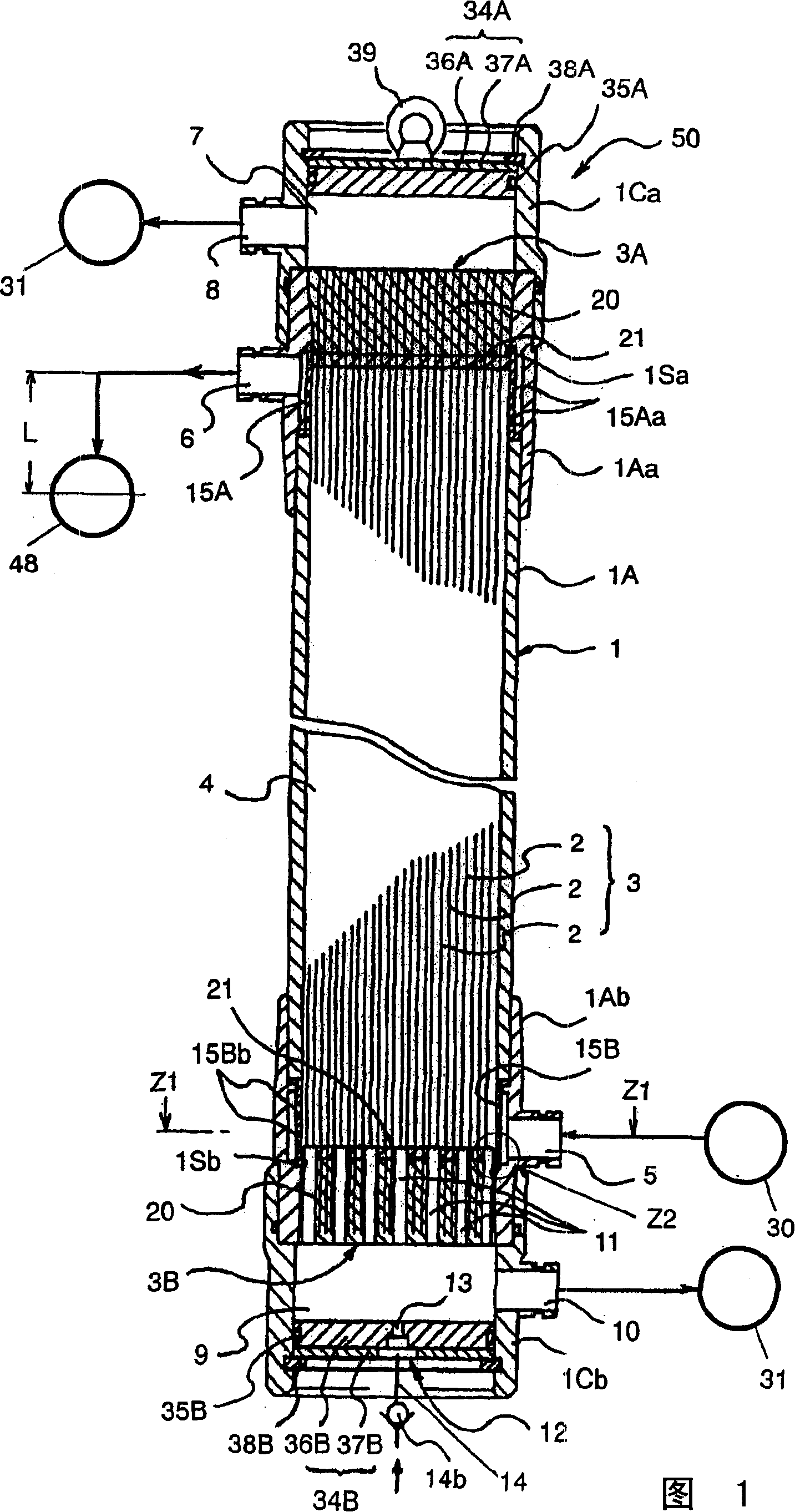

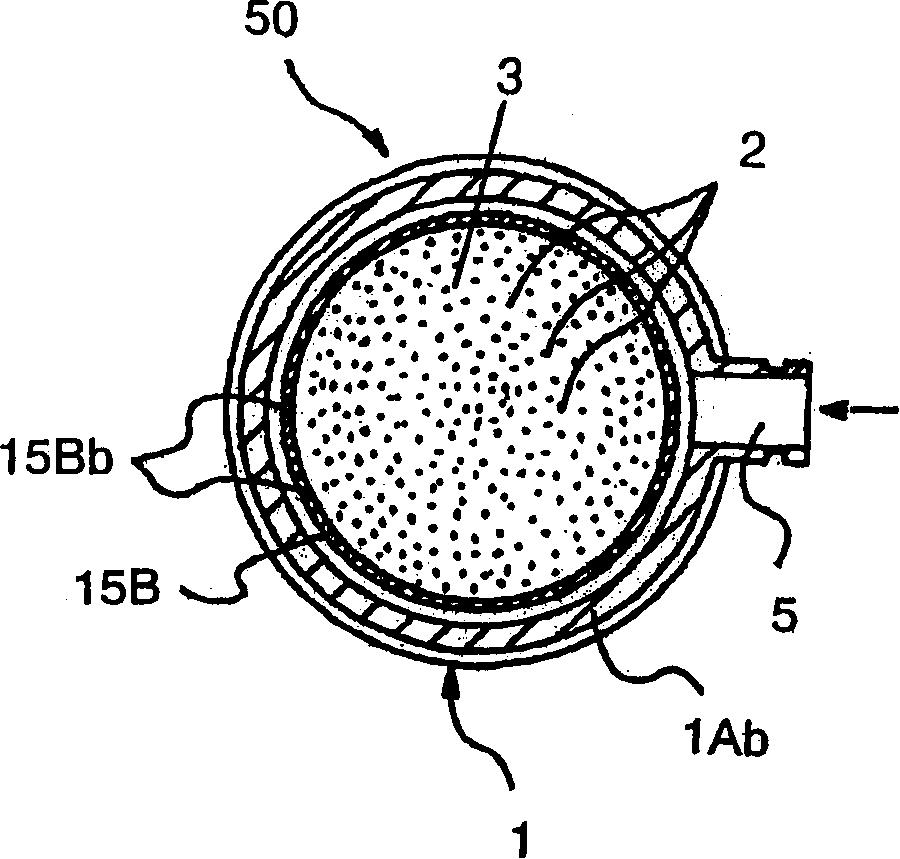

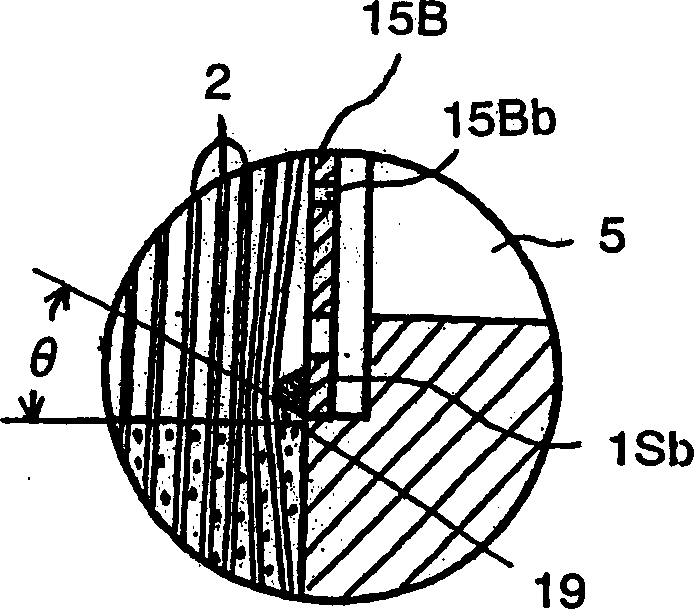

[0201] A cylindrical casing 1 (inner diameter: 194 mm, outer diameter: 216 mm) made of polyvinyl chloride resin, into which 12,000 hollow fiber membranes 2 (outer diameter: 1.3 mm, inner diameter: 0.9 mm) made of polyacrylonitrile resin are inserted ).

[0202] 35 parts by weight of aliphatic polyamine-based curing agent (LST868 H8, produced by Vantico) is mixed with 100 parts by weight of bisphenol F type epoxy resin (LST 868 R8), and the mixture is stirred at 25 °C and desiccated by a vacuum drier. As a result, the resin used for molding the first sealing body 3A and the second sealing body 3B is made. The prepared resin was injected using a tube pump at a rate of 20 g / min to achieve potting, resulting in a hollow fiber membrane module 50 .

[0203] The sealing bodies 3A and 3B are cut radially with a rotary blade of a pick saw type. There is no crack in the cut surface, and the sealing bodies 3A and 3B are not separated from the casing 1 .

example 2

[0211] Cylindrical jacket 1 (inner diameter: 194mm, outer diameter: 216mm, minimum internal cross-sectional area 238cm 2 ), made of polyvinyl chloride resin, into which 12,000 hollow fiber membranes 2 (outer diameter: 1.3 mm, inner diameter: 0.9 mm) made of polyacrylonitrile resin were inserted.

[0212] A potting resin prepared as described below was injected at a rate of 20 g / min using a tube pump, and a hollow fiber membrane module 50 was produced by static potting. Excluding the first sealing body 3A and the second sealing body 3B, the effective membrane area of the hollow fiber membrane 2 at the filter cavity 4 is 150 cm. 2 , the filling rate of the hollow fiber membrane 2 was 54%.

[0213] [Preparation of potting resin]

[0214] Bisphenol F epoxy resin (LST868 R8, produced by Vantico)

[0215] 100 parts by weight

[0216] Aliphatic polyamine-based curing agent (LST868 H8, produced by Vantico)

[0217] 35 parts by weight

[0218] The viscosity of the resin obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com