Environment protection type ceramic fibre needling blanket

A technology of ceramic fiber and needle-punched blanket, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc. It can solve the problems of a large amount of dust and particulate matter, and achieve the effect of stable fiber quality, high strength and soft fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

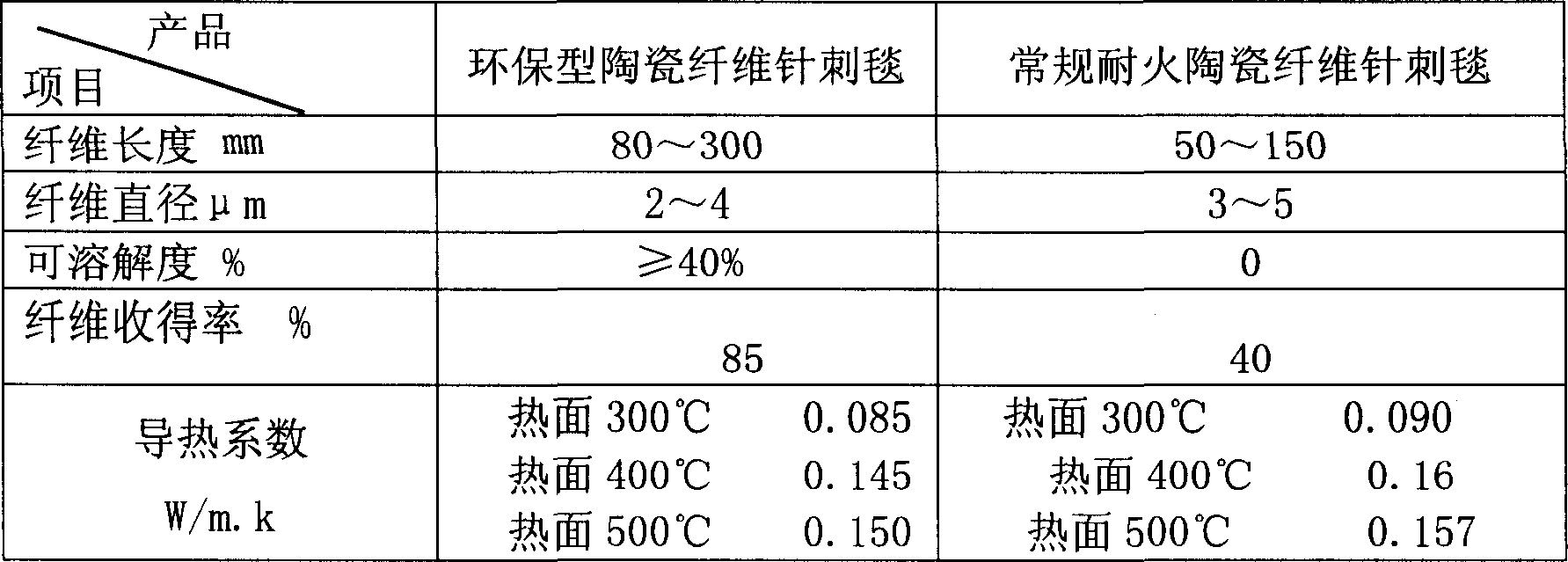

Image

Examples

Embodiment 1

[0012] Example 1 Raw material weight ratio: silicon dioxide: aluminum oxide: magnesium oxide = 55:40:4; the raw material is melted at 1700-1900°C, and at 1550-1700°C, it is formed into fibers by blowing or centrifugal spinning process The ceramic fiber is made, the fiber performance is slightly acidic, its pH is about 6.1±, and the non-fibrous matter (slag ball) is less than 8%; after collecting cotton, it is needled into a blanket, and the needled blanket blank passes through 700-900°C The high temperature is shaped into a blanket, and the ceramic fiber needle-punched blanket with soft texture is obtained by cutting. Because the raw material is easy to obtain and its melting temperature is low, the product cost is low, which is beneficial to popularization and application of the product.

[0013] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com