Carbon nano tube film micromechanical infrared detector

A carbon nanotube thin film, infrared detector technology, applied in the field of infrared detectors, can solve the problems of large volume, low sensitivity, inability to achieve performance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

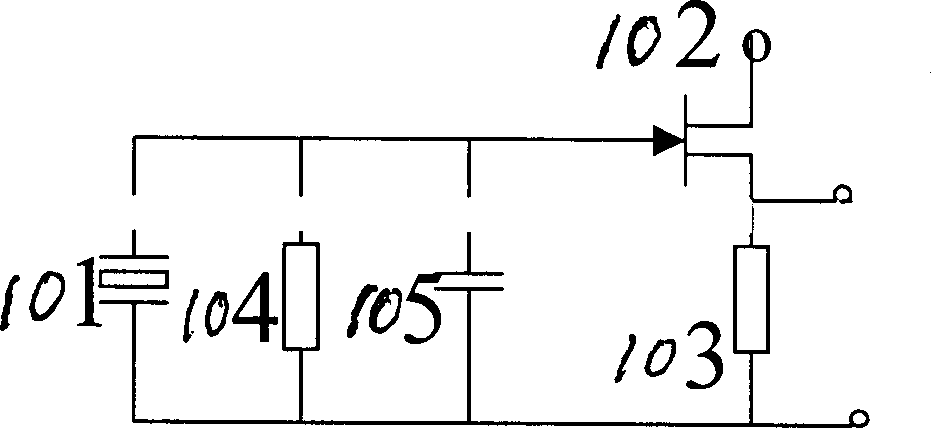

Problems solved by technology

Method used

Image

Examples

Embodiment

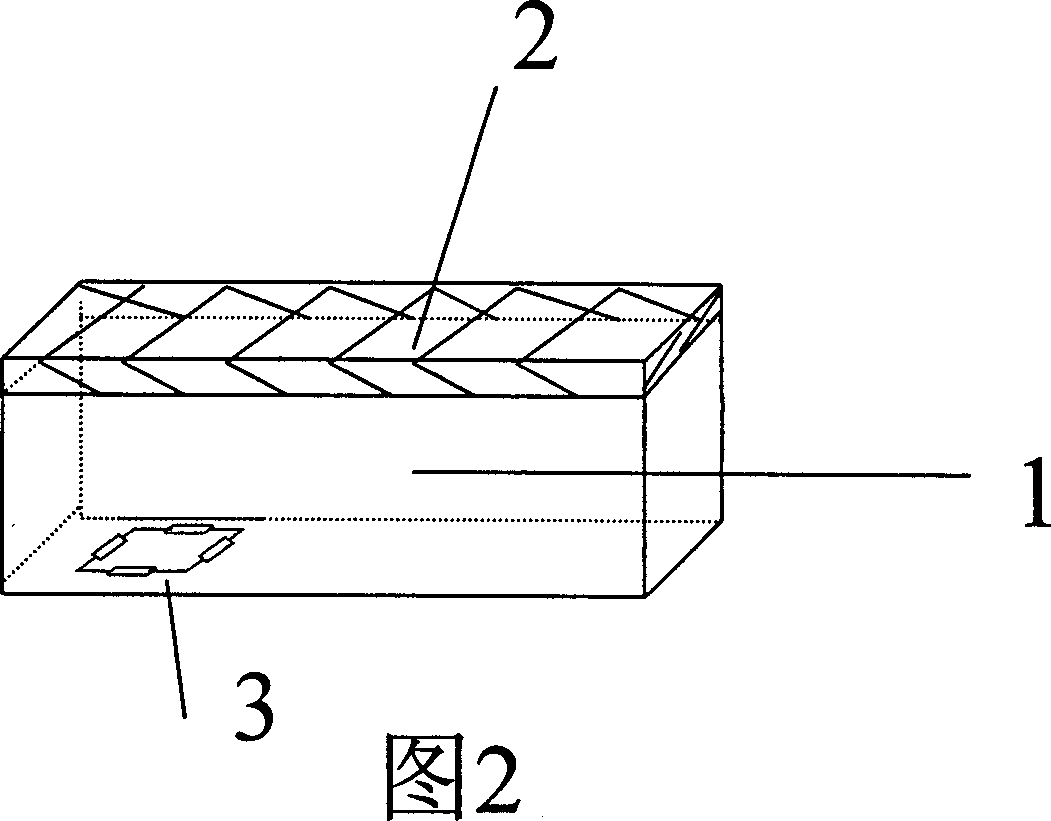

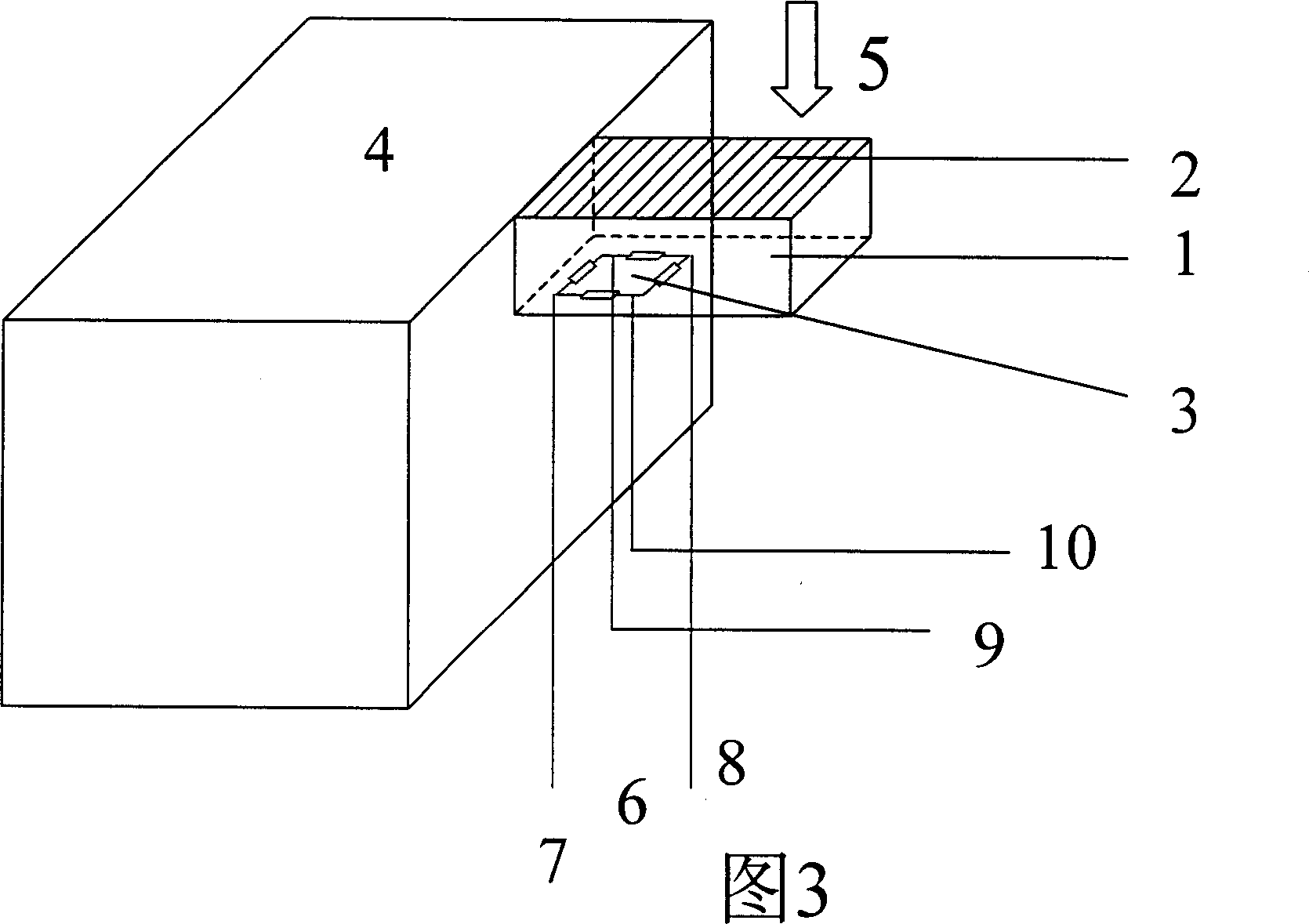

[0021] Embodiment: Refer to Fig. 2 and Fig. 3, Fig. 2 is a structural diagram of a carbon nanotube thin film silicon micro-cantilever beam resonator, including a semiconductor base material 1 and a carbon nanotube thin film 2 grown thereon, and a pick-up circuit 3 . Figure 3 is a schematic diagram of the overall structure of a carbon nanotube thin-film silicon micro-cantilever infrared detector, including a base 4, a radiation window 5, a power supply 6, a power supply connection 7, a power supply connection 8, and an output signal connection 9 and an output signal connection 10.

[0022] Micromachine 1 refers to micromechanical resonant devices, which can be microcantilever beams, microbridges, and micromembranes (square membranes or circular membranes), etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com