High creep resistance rareearth contained tin base leadless soldering-flux and preparation method thereof

A lead-free solder and creep technology, which is applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of lead pollution sensitivity, brittleness, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

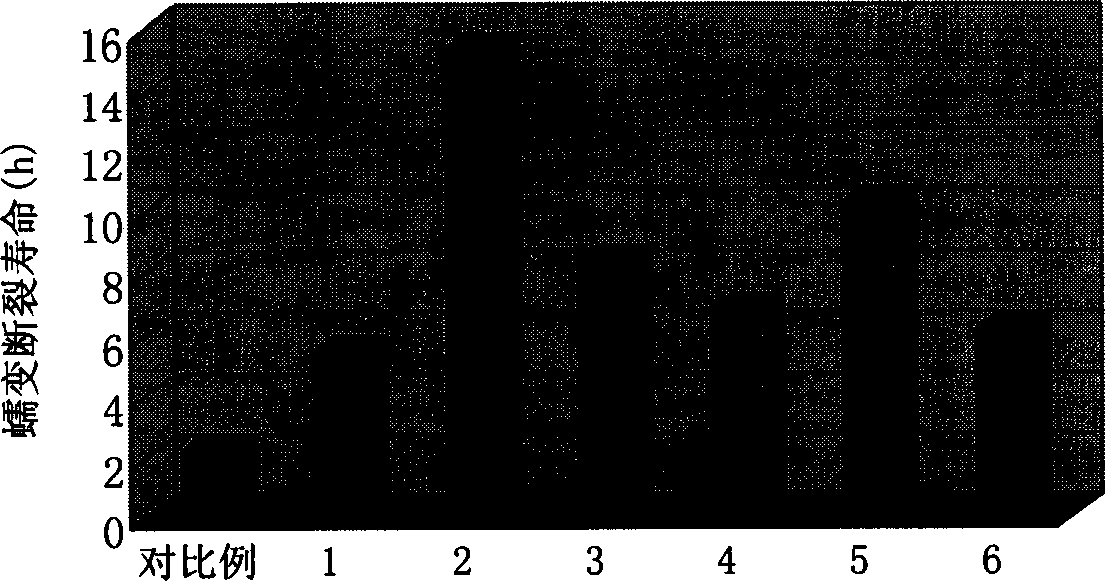

Examples

example 1

[0021] Example 1: 26 grams of potassium chloride and 20 grams of lithium chloride mixed salt were melted at 460 ° C and poured on 97.775 grams of tin. Raise the temperature of the furnace to 620°C to melt the tin and the mixed salt, then add 2 grams of Ag and 0.2 grams of Cu to the tin liquid while stirring continuously to form an alloy; The base mixed rare earth is quickly pressed into the above molten alloy and stirred continuously until the rare earth is completely melted. Keep warm for 1 hour, stirring constantly to homogenize the alloy. Stand still and take out the furnace, and remove the mixed salt on the surface after the alloy is solidified. Lower the furnace temperature to 360°C to reheat and melt the solder block, and then pour it into strips on the angle iron for use.

example 2

[0022] Example 2: 26 grams of potassium chloride and 20 grams of lithium chloride mixed salt were melted at 460°C and poured on 96.0 grams of tin. Raise the temperature of the furnace to 780°C, melt the tin and the mixed salt, add 2 grams of Ag and 1 gram of Cu to the tin liquid, and stir continuously at the same time to form an alloy; The base mixed rare earth is quickly pressed into the above molten alloy and stirred continuously until the rare earth is completely melted. Keep it warm for 1.5 hours and keep stirring to homogenize the alloy. Stand still and take out the furnace, and remove the mixed salt on the surface after the alloy is solidified. Lower the furnace temperature to 380°C to reheat and melt the solder block, and then pour it into strips on the angle iron for use.

example 3

[0023] Example 3: 23.4 grams of potassium chloride and 18 grams of lithium chloride mixed salt are poured on 94.775 grams of tin after melting at 450°C. Raise the temperature of the furnace to 650°C to melt the tin and the mixed salt, then add 5 grams of Ag and 0.2 grams of Cu to the tin liquid while stirring continuously to form an alloy; The base mixed rare earth is quickly pressed into the above molten alloy and stirred continuously until the rare earth is completely melted. Keep warm for 1 hour, stirring constantly to homogenize the alloy. Stand still and take out the furnace, and remove the mixed salt on the surface after the alloy is solidified. Lower the furnace temperature to 360°C to reheat and melt the solder block, and then pour it into strips on the angle iron for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com