Middle sole and its production process and shoes with the middle sole

A manufacturing method and square technology, applied in the field of shoe midsoles, can solve the problems of not feeling high-grade, not light, heavy materials, etc., and achieve the effects of excellent shoe midsoles, long life and less adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

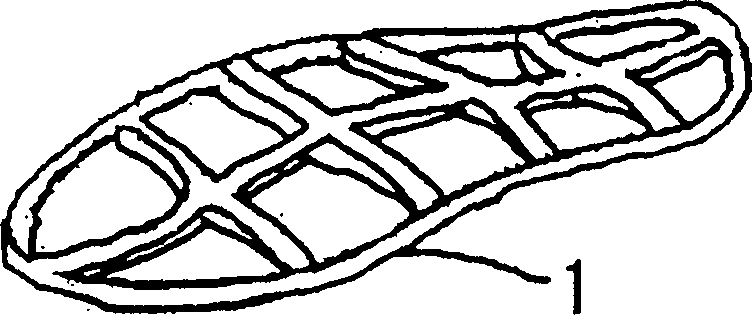

[0082] figure 1 An example of the shoe midsole of the present invention is shown.

[0083] A shoe midsole made of CRB ceramics was fabricated as follows.

[0084] (Production of CRB ceramic front skeleton)

[0085] 75 kg of defatted rice bran obtained from rice bran and 25 kg of liquid phenolic resin (resol resin) were mixed and kneaded while being heated to 50 to 60°C. A homogeneous mixture with plasticity can be obtained.

[0086] The mixture was once fired at 900° C. for 60 minutes in a nitrogen atmosphere using a rotary furnace. Next, the obtained carbonized fired product was sieved through a 100-mesh sieve to obtain carbonized powder with a particle diameter of 50 to 250 μm.

[0087] 75 kg of the obtained carbonized powder and 25 kg of solid phenolic resin (resole resin) were mixed and kneaded while being heated to 100 to 150°C. Plastics of CRB ceramic pre-skeletons can be obtained as homogeneous mixtures with plasticity.

[0088] (Forming of shoe midsole)

[0089]...

Embodiment 2

[0098] (Production of CRB ceramic front skeleton)

[0099] 75 kg of defatted rice bran obtained from rice bran and 25 kg of liquid phenolic resin (resol resin) were mixed and kneaded while being heated to 50 to 60°C. A homogeneous mixture with plasticity can be obtained.

[0100] The mixture was once fired at 900° C. for 60 minutes in a nitrogen atmosphere using a rotary furnace. Next, the obtained carbonized fired product was sieved through a 100-mesh sieve to obtain carbonized powder with a particle diameter of 50 to 250 μm.

[0101] 75 kg of the obtained carbonized powder and 25 kg of solid phenolic resin (resole resin) were mixed and kneaded while being heated to 100 to 150°C. The CRB ceramic pre-skeleton can be obtained as a homogeneous mixture with plasticity.

[0102] (Forming of shoe midsole)

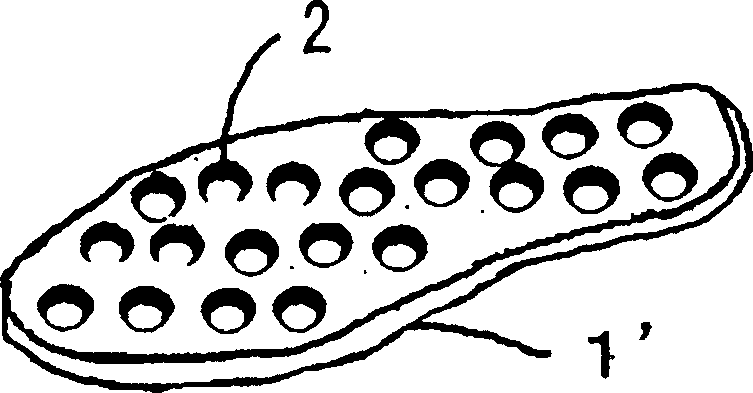

[0103] Next, put Figure 4 The skeleton 1 ' of the foot-shaped plate-like body that shows hole 2 is made of aluminum is put into metal mould, and the plastic thing of skele...

Embodiment 3

[0108] (Manufacturing of the front skeleton of RB ceramics)

[0109] 75 kg of defatted rice bran obtained from rice bran and 25 kg of liquid phenolic resin (resol resin) were mixed and kneaded while being heated to 50 to 60°C. Plastics can be obtained as a homogeneous mixture of RB-ceramic pre-skeletons with plasticity.

[0110] (Forming of shoe midsole)

[0111] Next, put Figure 4 The skeleton 1 of the foot-shaped plate-shaped body with holes 2 made of the shown anodized aluminum is put into a metal mold, and the plastic of the front skeleton of the RB ceramic is pressurized with a pressure of 30Mpa. The temperature of the metal mold is 150°C.

[0112] Take out the molded body from the metal mold, raise the temperature to 500°C at a rate of 1°C / min in a nitrogen atmosphere, then heat at a rate of 2°C / min, and heat treat at 700°C for about 120 minutes. Next, it is naturally cooled to obtain a molded body.

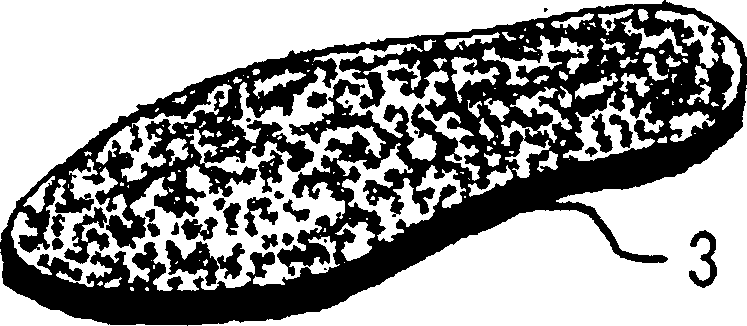

[0113] image 3 The shown midsole 1 is characterized as follows....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com