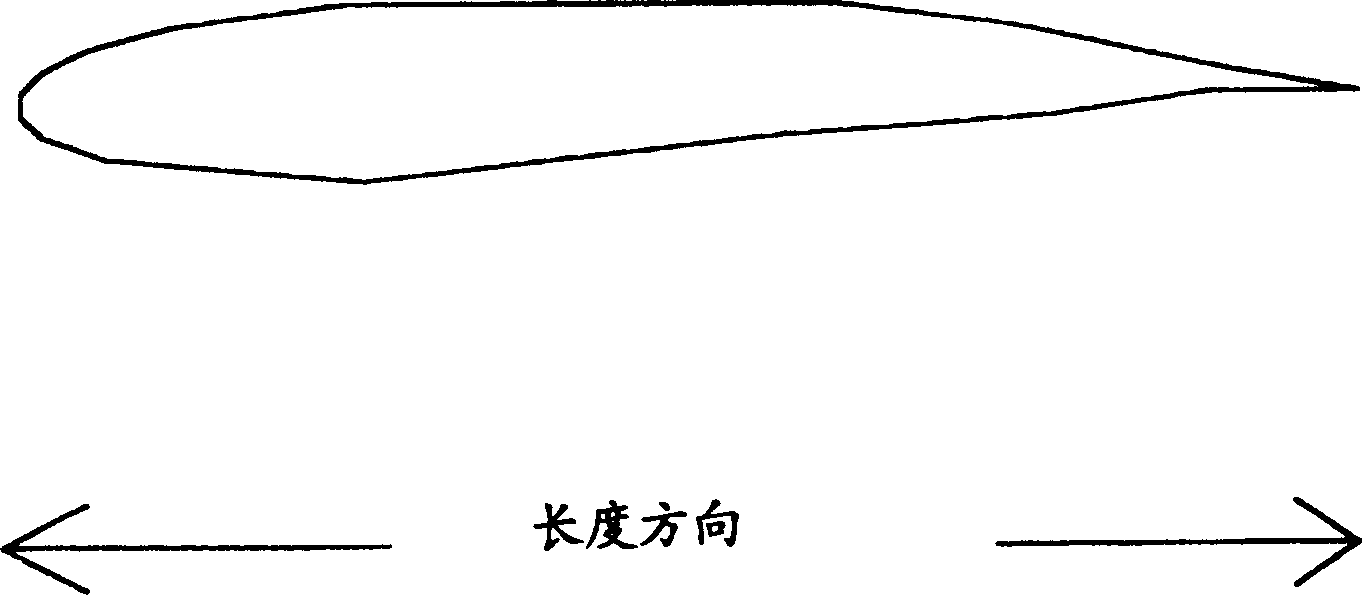

Shark's fin shaped food

A shark fin and food technology, which is applied in the field of shark fin-like food compositions, can solve the problems of rough feeling, poor food taste, insufficient pectin elasticity or transparency, etc., and achieve the effect of improving formability and food taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

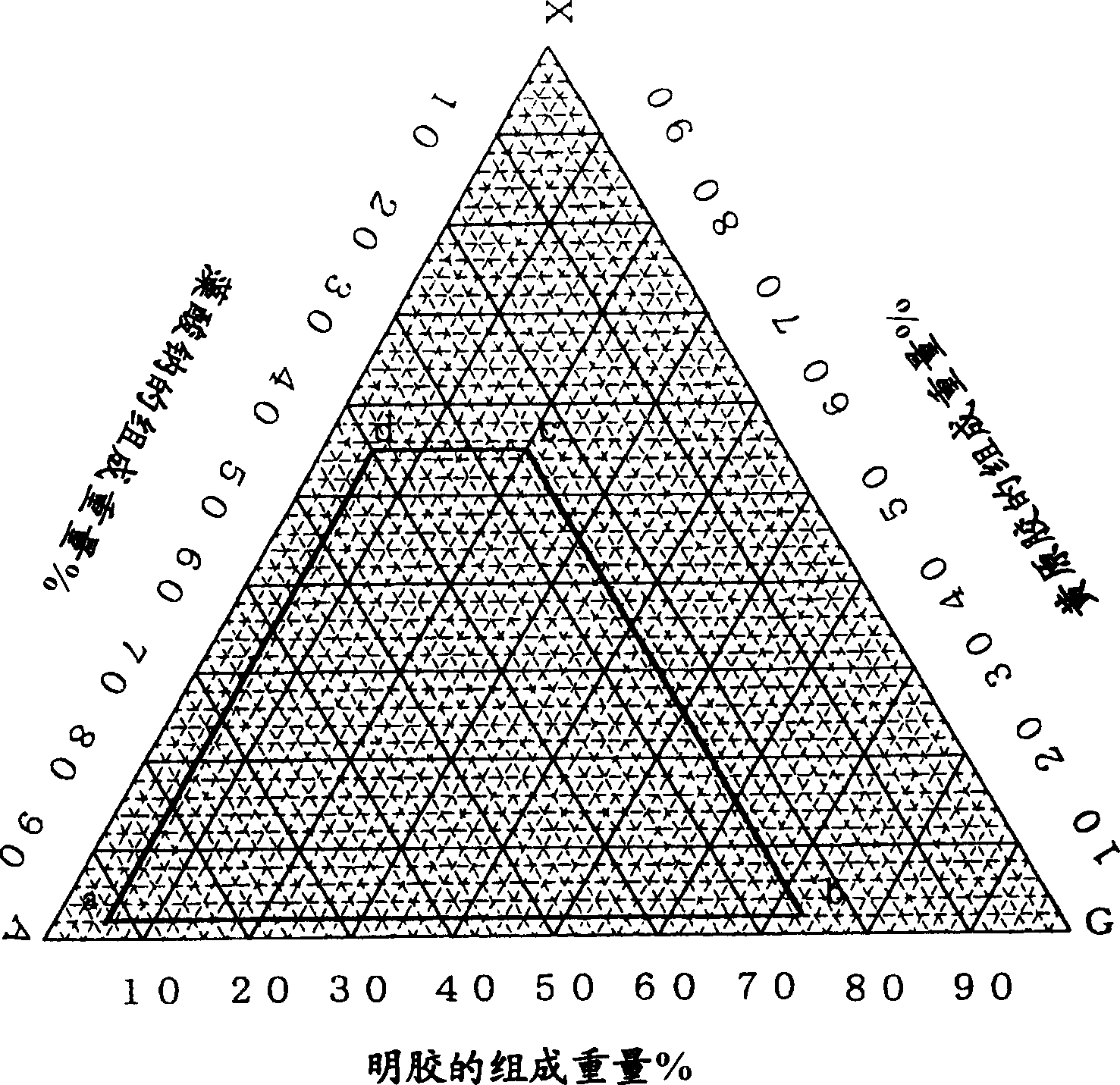

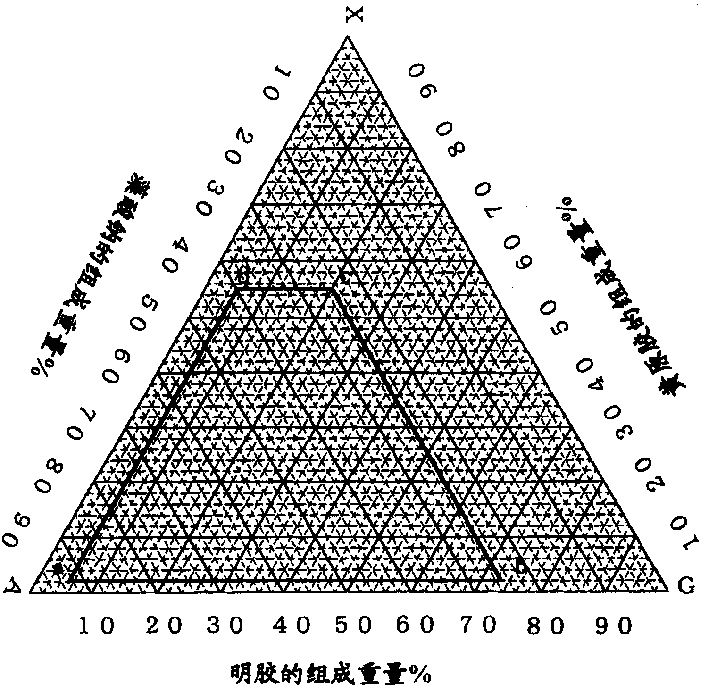

[0041] After dissolving 4.2% by mass of sodium alginate, 1.5% by mass of gelatin, and 0.3% by mass of xanthan gum in warm water at 50° C., it was defoamed under reduced pressure. This aqueous solution was sprayed onto the rotating drum through a nozzle of 2.1 m / m to obtain a streamlined shark fin-like molded product. It is directly placed in 1% mass calcium chloride aqueous solution for 15 minutes, fully washed with water, and the shark fin-like food is obtained.

[0042] The composition mass % A, G, and X of sodium alginate, gelatin, and xanthan gum in the obtained shark fin-like food were 70, 25, and 5, respectively, and the moisture content was 94.5 mass %.

[0043] It was made into soup, and compared with natural shark's fin soup, the results of evaluation are shown in Table 1.

[0044] As shown in Table 1, the shark's fin-like food obtained in Example 1 resembles natural shark's fin, is also resistant to hot water when making soup, has no change in taste or shape, and ha...

Embodiment 2

[0064] After dissolving 2.7% by mass of sodium alginate, 1.2% by mass of gelatin, and 2.1% by mass of xanthan gum in warm water at 60° C., it was defoamed under reduced pressure. This aqueous solution was sprayed onto the stream of 1% by mass calcium chloride aqueous solution through a nozzle with a diameter of 1.5 m / m to obtain a streamlined shark fin-like molded product. It is directly placed in 1% mass calcium chloride aqueous solution for 15 minutes, fully washed with water, and the shark fin-like food is obtained.

[0065] The obtained shark fin-like food had sodium alginate, gelatin, and xanthan gum whose composition mass % A, G, and X were 45, 20, and 35, respectively, and the water content was 94.4 mass %.

[0066] It is made into soup, compared with natural shark's fin sample, and the result of evaluation is as shown in table 1.

Embodiment 3

[0068] 2.8% by mass of sodium alginate, 3.6% by mass of gelatin, and 1.6% by mass of xanthan gum were dissolved in warm water at 60°C, and defoamed under reduced pressure. The aqueous solution is given a pressure of 2kg / cm at 60°C 2 The air pulse of G (pressurization time 0.5 seconds, pressure stop time 1.7 seconds) is sprayed onto the fluid of 1 mass % calcium chloride aqueous solution from a nozzle with a diameter of 1 m / m to obtain a streamlined shark fin-like molded product. It is directly placed in 1% mass calcium chloride aqueous solution for 15 minutes, fully washed with water, and the shark fin-like food is obtained.

[0069] The sodium alginate, gelatin, and xanthan gum of the obtained shark fin-like food had composition mass % A, G, and X of 35, 45, and 20, respectively, and a water content of 92.8 mass %.

[0070] It is made into soup, and compared with natural shark's fin sample, the result of evaluation is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com