Process for synthesizing different crystal form one-dimensional single crystal mangnesium dioxide nano wire

A manganese dioxide, single crystal nanotechnology, applied in chemical instruments and methods, manganese oxide/hydroxide, single crystal growth and other directions, to achieve the effects of simple process, stable product quality and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

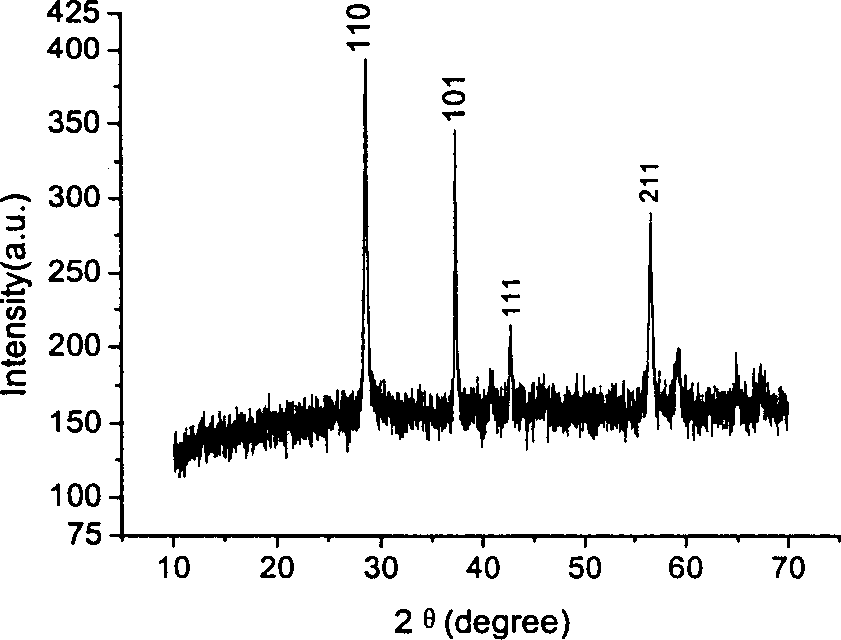

Embodiment 1

[0021] Weigh 1.3g of analytically pure manganese sulfate and 1.8g of ammonium persulfate into a 40ml stainless steel pressure-resistant reactor, add deionized water, and stir to form a uniform solution. Seal the reactor and react at 140°C for 12h. Then cool to room temperature, open the reaction kettle, filter with Buchner funnel, and wash with deionized water to obtain a black powder. The product is identified as β-type manganese dioxide by X-ray powder diffraction; the appearance of the product detected by TEM electron microscope: the diameter is 40-100 nanometers, and the length is 2.5-4.0 microns. Single nanowire electron diffraction proves that the product is a single crystal. Under the same conditions, control the reaction temperature at 100, 160, and 220°C, and use manganese chloride or manganese carbonate as the divalent manganese salt to obtain β-type manganese dioxide one-dimensional single-crystal nanowires. Different, the aspect ratio of the product is slightly d...

Embodiment 2

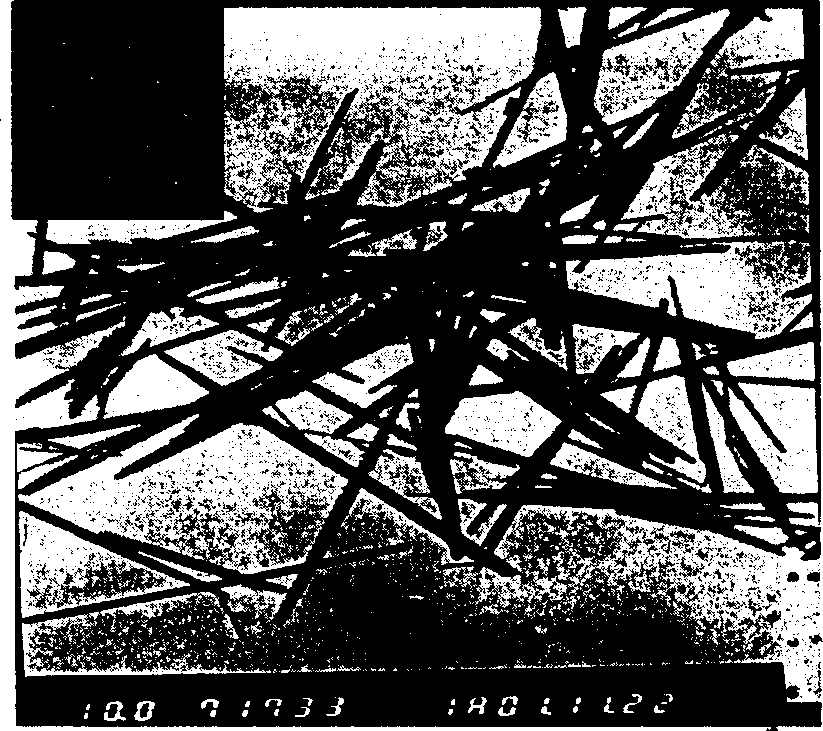

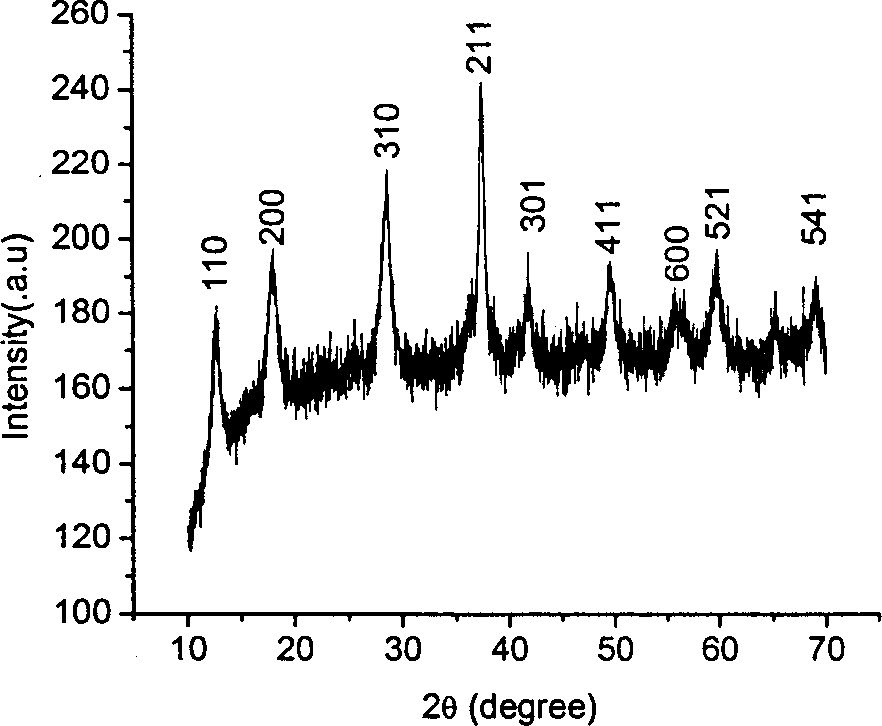

[0023] Weigh 1.3g of analytically pure manganese sulfate, 1.8g of ammonium persulfate and 3g of ammonium sulfate into a 40ml stainless steel pressure-resistant reactor, add deionized water, and stir to form a uniform solution. Seal the reactor and react at 120°C for 12h. Then cool to room temperature, open the reaction kettle, filter with Buchner funnel, and wash with deionized water to obtain a black powder. The product is identified as α-type manganese dioxide by X-ray powder diffraction; the appearance of the product detected by TEM electron microscope: the diameter is 5-20 nanometers, and the length is 3-10 microns. Single nanowire electron diffraction proves that the product is a single crystal. Under the same conditions, control the reaction temperature at 100, 160, and 220°C, and use manganese chloride or manganese carbonate as the divalent manganese salt to obtain α-type manganese dioxide one-dimensional single crystal nanowires. According to the preparation condition...

Embodiment 3

[0025] Weigh 0.3g of analytically pure manganese sulfate and 0.5g of potassium permanganate, place them in a 40ml stainless steel pressure-resistant reactor, add deionized water, and stir to form a uniform solution. React in a sealed reactor at 180°C for 6h. Then cool to room temperature, open the reaction kettle, filter with Buchner funnel, and wash with deionized water to obtain a black powder. The divalent manganese salt can be manganese chloride or manganese carbonate, and the reaction can be carried out at 100, 160, 220°C. It was detected as α-type manganese dioxide nanorods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com