Curved compensating transformer and its phase-shift voltage regulating method

A transformer and zigzag technology, applied in the field of motor and transformer disciplines, can solve problems such as inconvenient structure and complexity, and achieve the effect of easy on-load voltage regulation and energy-saving transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

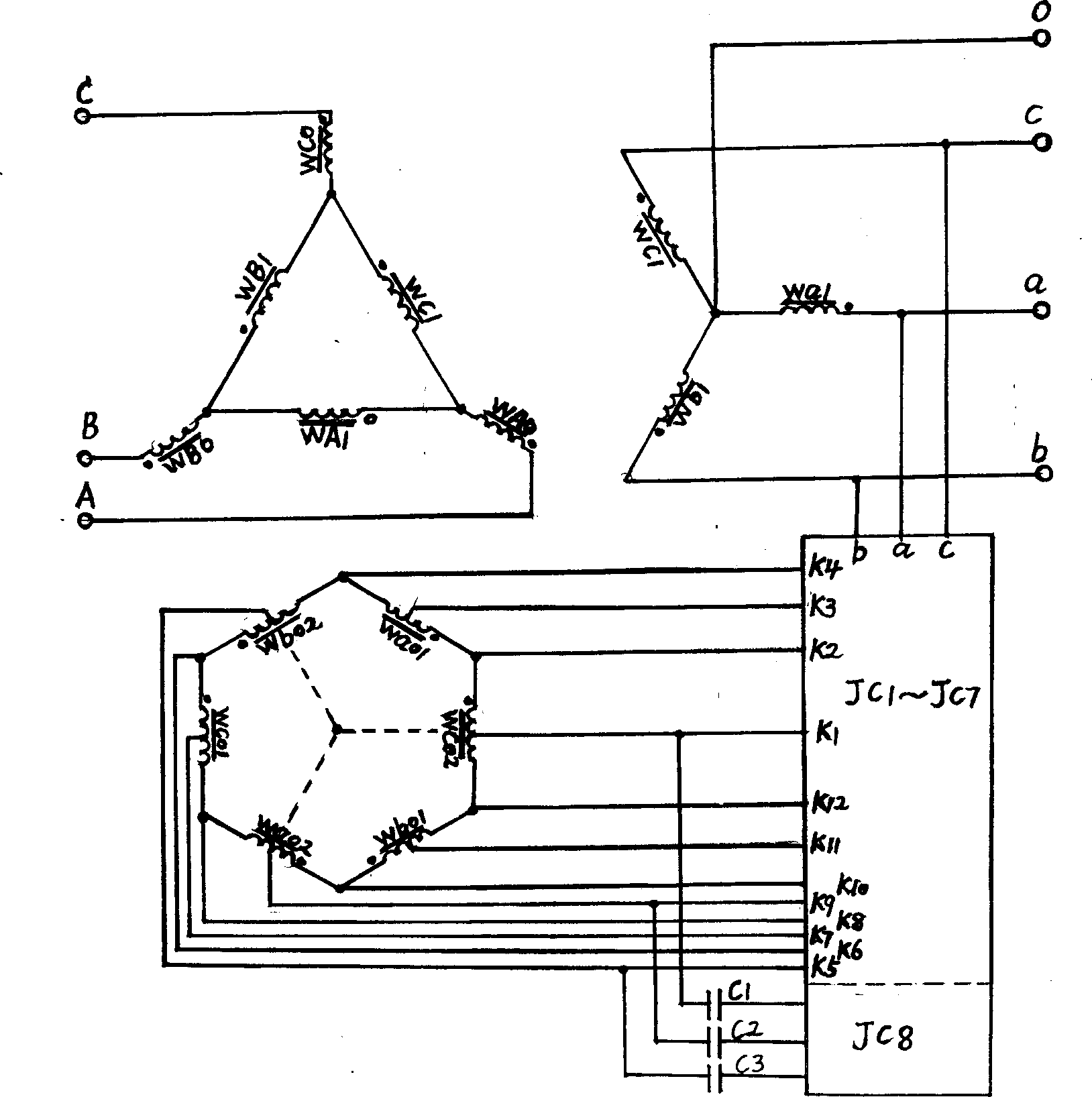

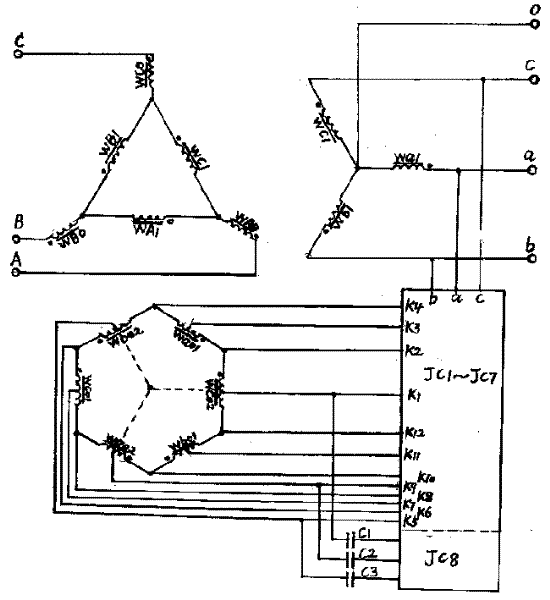

Embodiment 1

[0012] In this example, the design voltage ratio of the distribution transformer is 10 / 0.4KV, and the voltage is adjusted to ±6×2.5%UH. The iron core is arranged on the upper part, and the cross-sectional ratio of the two iron cores can be taken as 2:1. WAo, WBo, and WCo high-voltage windings are respectively installed in the three core columns of the adjusting core, and correspondingly installed with Wao1 and Wao2, Wbo1 and Wbo2, Wco1 and Wco2 low-voltage windings, and K3 and K9, K11 and K5 are respectively drawn out in the middle of the low-voltage windings. , K7 and K1 regulation terminals. Three pairs of high and low voltage windings, WA1 and Wa1, WB1 and Wb1, WC1 and Wc1, are respectively installed on the three cores of the main body. The wiring method of the high-voltage combined winding is: the first end (end of the same name) of the winding of WA1, WB1 and WC1 is connected to the end of the previous winding (the end of the same name) to form a delta connection, and it...

Embodiment 2

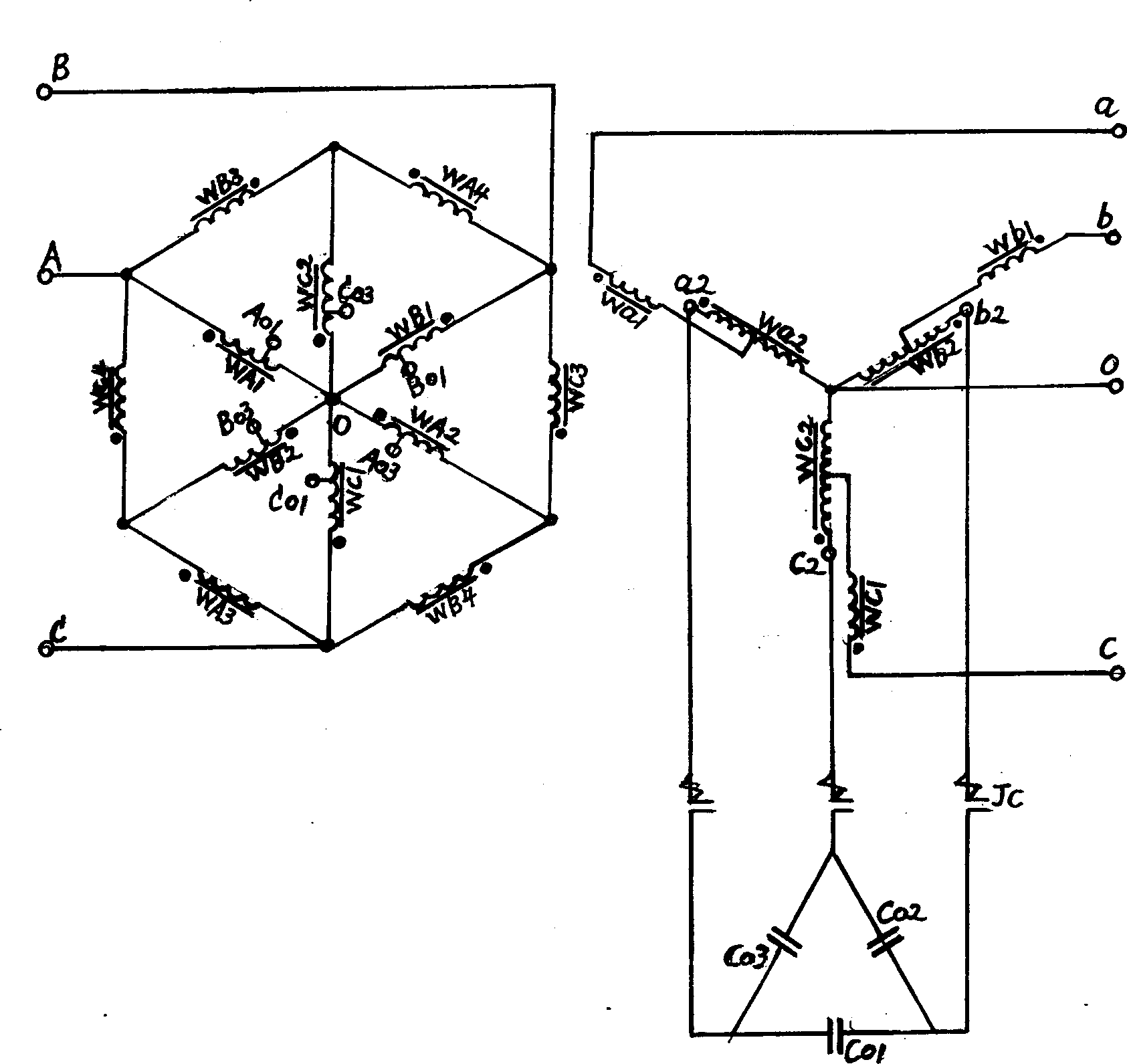

[0014] Embodiment 2 In this example, the transformer voltage ratio is designed to be 10 / 0.4KV, and the voltage adjustment range is +7×2.5% to -4×2.5% UH. The iron core and winding are designed as follows: the main iron core and the adjustment iron core placed on the upper part adopt a conjugate "Tian"-shaped combined structure, the upper and lower core columns are equal to the core cross-sections of the upper and lower cross yokes, and the middle cross yoke is larger than the iron core of the core column. The ratio of the cross-sectional area is 1:3, and the window height of the upper and lower iron cores is 1:1.5; the cross-sectional ratio of the high-voltage winding of the main core and the high-voltage winding of the regulating core is √3:1, and the ratio of turns of the corresponding low-voltage winding is also √3∶1; the low-voltage winding of the adjusting iron core increases the number of turns by √3 times in the form of self-coupling; WA2 and WA4, WB2 and WB4, WC2 and WC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com