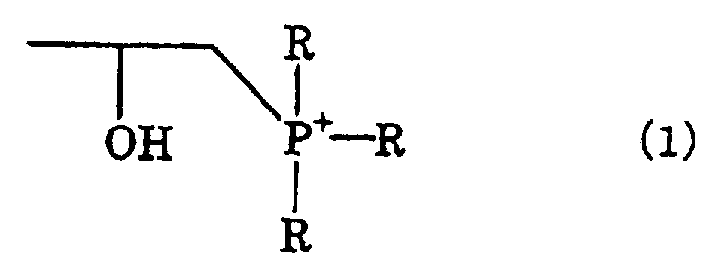

Cation electrophoretic coating composition comprising phosphonio group

A cationic electrophoresis and composition technology, applied in electrophoretic coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor compatibility, high water solubility, and failure to display sufficient anti-corrosion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0127] Preparation Example 1 Preparation of phosphonium group-containing compound (based on monofunctional epoxy compound)

[0128] The reactor was charged with 325.0 g of NH-300P (epoxy equivalent 325, nonylphenyl glycidyl ether; product of Sanyo Chemical Ind., Ltd.), and heated to 100°C. Then an aqueous solution prepared from 208.2 g of tris(3-hydroxypropyl)phosphine (Hishichaulin P-500, a product of Nippon Chemical Industrial Co., Ltd.), 60.0 g of acetic acid and 144.0 g of deionized water was gradually added, and the resulting mixture was kept at 75°C.

[0129] After it was confirmed that the acid value was stabilized at not more than 5, 251.5 g of deionized water was added, followed by cooling. Then the product (non-volatile matter (hereinafter often referred to as NV) = 60%, number average molecular weight 590, phosphonium group content 1.7 meq / g, conversion rate of epoxy group to phosphonium group = 100% ). The conversion from epoxy groups to phosphonium groups was d...

preparation Embodiment 2

[0130]Preparation Example 2 Preparation of Compounds Containing Phosphonium Groups (Based on Novolac Epoxy Compounds)

[0131] Into the reaction vessel were added 2426.4 g of YDCN-703 (epoxy equivalent 202.2, cresol novolac epoxy resin, 12 cores, product of Tohto Chemical Co.) and 1257.0 g of ethylene glycol monobutyl ether. The resulting mixture was heated at 130°C under a nitrogen atmosphere to dissolve uniformly.

[0132] Then, after cooling to 100°C, an aqueous solution prepared from 1619.1 g of Hishicaulin P-500, 432.0 g of acetic acid, and 1728 g of deionized water was gradually added, and then, cooled and kept at 75°C. The reaction was continued until the acid value was not greater than 5.

[0133] After it was confirmed that the acid value was stabilized at not more than 5, 1492.5 g of deionized water was added, followed by cooling. (NV=50%, number average molecular weight 4500, phosphonium group content 1.6 meq / g, conversion rate of epoxy group into phosphonium grou...

preparation Embodiment 3

[0134] Preparation Example 3 Preparation of a compound containing a phosphonium group (based on a novolac epoxy resin (containing an unsaturated group))

[0135] 2426.4 g of YDCN-703 (epoxy equivalent weight 202.2, cresol novolac epoxy resin, 12 cores, product of Tohto Chemical Company) and 1682.4 g of enzyme-catalyzed linseed oil fatty acid were added to the reactor, and the resulting mixture was heated to 120 °C. After uniform dissolution, 7.28 g of ethyltripropylphosphonium iodide was added. After confirming that the acid value was not more than 1, 2426.4 g of ethylene glycol monobutyl ether was added.

[0136] Then, an aqueous solution prepared from 1349.3 g of Hishicaulin P-500, 360.0 g of acetic acid and 3384.4 g of deionized water was added gradually, maintaining the resulting mixture at 75°C.

[0137] After it was confirmed that the acid value was stabilized at not more than 5, the resulting reaction mixture was cooled, and the product was discharged. (NV=50%, numbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com