Light grouted wall and its construction method

A technology for grouting walls and lightweight walls, which is applied to walls, building components, buildings, etc., can solve the problems of high housing cost, uneven wall surface, high wall density, etc., achieve short construction period, no environmental pollution, increase The effect of using the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

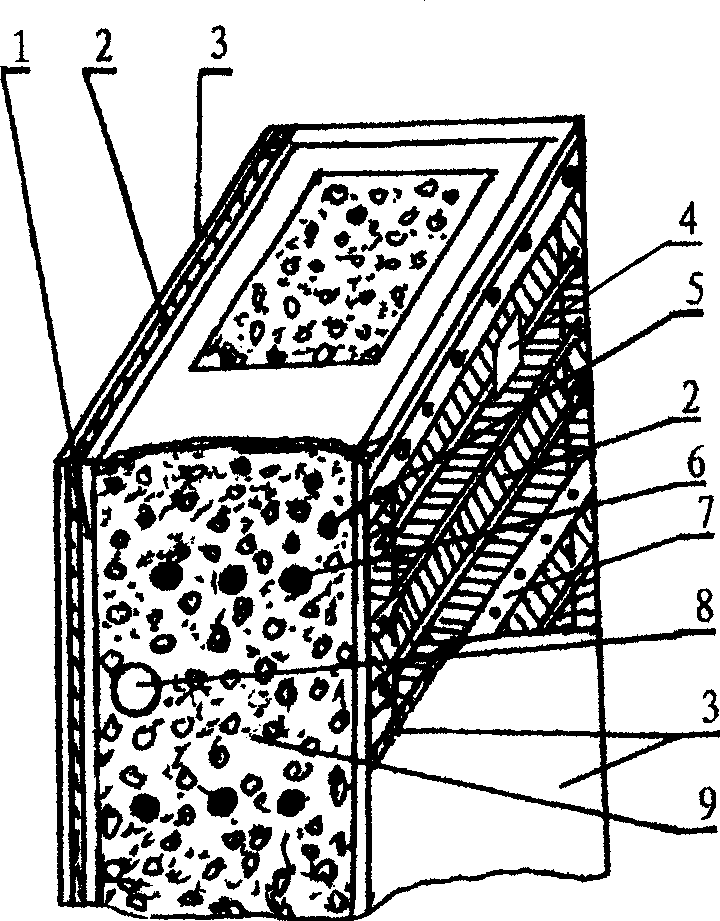

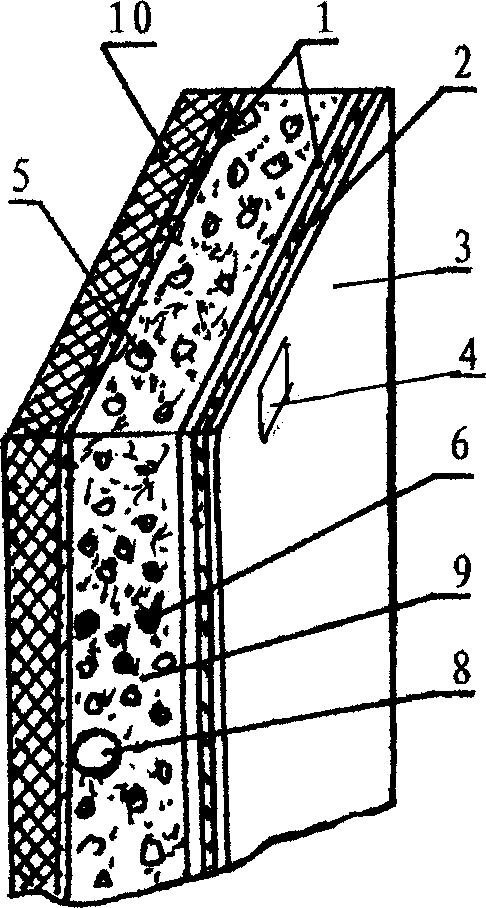

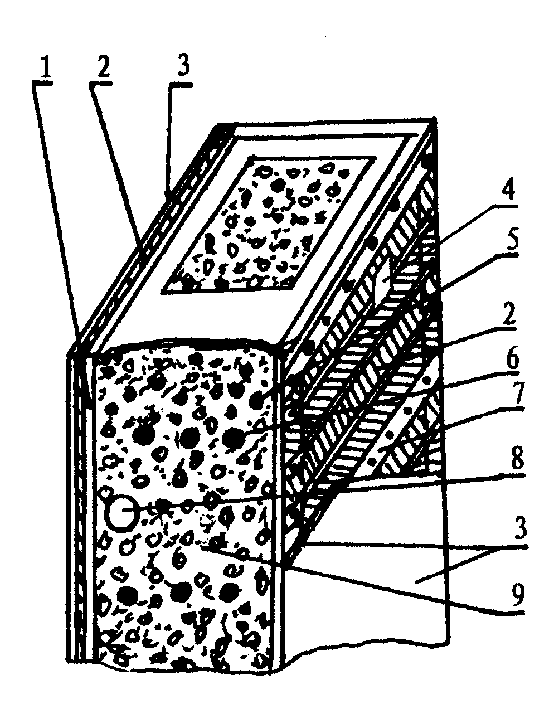

[0025] figure 1 Shown is a schematic diagram of the metal mesh lightweight grouted wall structure. It adopts a wall panel skeleton 1 and a metal mesh 2 with a mesh bar 7 punched out of a thin metal plate (such as a galvanized iron plate) (such as the I type, CF type, and U type in the inventor's application number 01279443.0 patent). (its structure is as the inventor's application number is the mesh with ribs shown in 01279443.0 and the herringbone type metal net shown in 02209527.6 patent application), earlier skeleton 1 is inserted by horizontal and vertical. If it is an inner wall (partition wall), it is generally required that the wall is thinner, and it is sufficient to fix the metal mesh 2 on the frame 1 with self-tapping screws around the frame 1; One side fixes the hard energy-saving plate 10, and the other side fixes the metal mesh 2 (such as figure 2 shown), or fix the metal mesh 2 or the hard energy-saving board 10 on both sides; first fix the metal mesh 2 or the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com