Process for shaping foamed latex product

A technology of natural latex and molding technology, which is applied in the field of molding technology of natural latex foam products, and achieves the effect of simple and easy molding technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of molding process of natural latex foam product provided by the invention, it comprises the steps:

[0024] 1) heating the coating (1) to soften it;

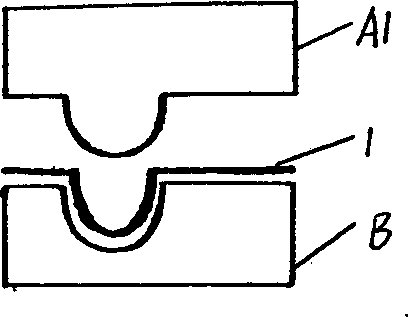

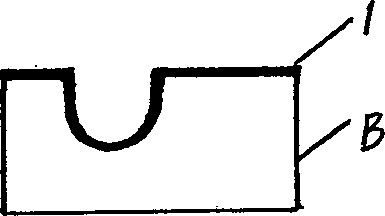

[0025] 2) The softened coating (1) is pre-shaped by the upper convex mold (A1) and the lower concave mold (B), and the molded coating (1) fits in the lower concave mold (B) without Move again, such as figure 1 , figure 2 Shown, in this process, control the temperature of mold up and down, to guarantee not to cause the coking of the soft natural latex foam foam (2) poured in the mould;

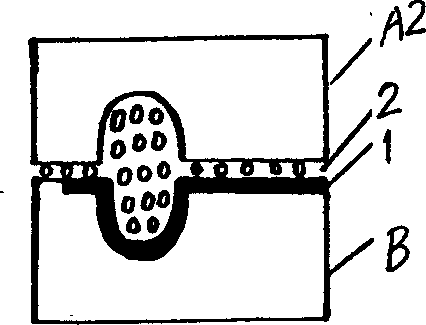

[0026] 3) Change the upper concave mold (A2) so that it is combined with the lower concave mold (B), and then pour soft natural latex foam (2) into the space between the upper concave mold (A2) and the lower concave mold (B). In the cavity, it can be extruded. like image 3 , Figure 4 shown.

[0027] The heating temperature of the coating (1) in the above-mentioned step 1) is not to make the coating coking, but it is advis...

Embodiment 2

[0029] The molding process of the present invention is identical with embodiment 1. The difference is that if the complexity of the product is high, it needs to be combined and extruded as a whole, such as Figure 5 As shown, finished products such as Figure 6 shown.

Embodiment 3

[0031] The present invention provides another molding technique of natural latex foamed product, it is characterized in that comprising the steps:

[0032] 1) Apply soft natural latex foam (2) on the covering (1), such as Figure 7 shown;

[0033] 2) Heating the soft natural latex foam (2), making it extruded in the cavity of the upper convex mold (A1) and the lower concave mold (B), and controlling the heating temperature to ensure the soft natural latex foam The foam (2) is dried until it is extruded by the mold without breaking and is not overheated so that it cannot be pressurized, such as Figure 8 shown.

[0034] The heating temperature of the natural latex foam (2) in the above step 2) is the best processing time when the latex foam is dried to 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com