Fuel cell system

A fuel cell and fuel technology, applied in the direction of fuel cells, solid electrolyte fuel cells, circuits, etc., can solve the problem of overcooling of fuel cell stacks, achieve the effect of reducing carbon deposition and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

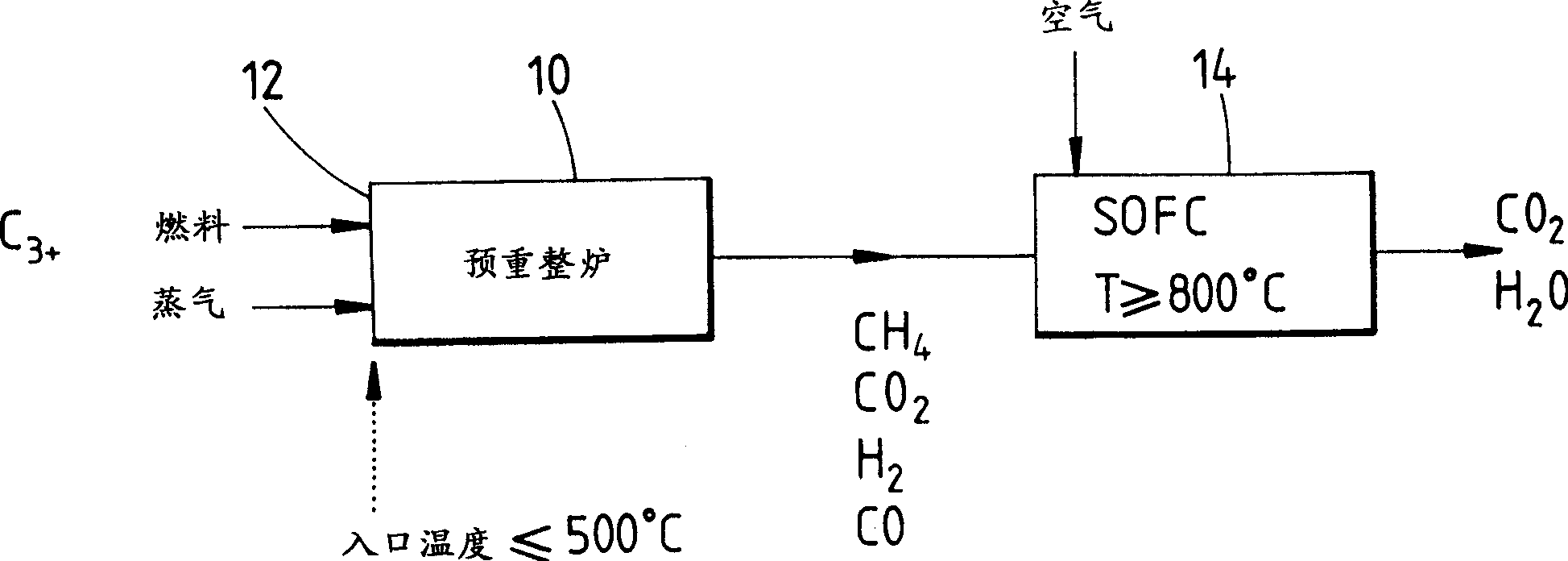

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] Propane was steam pre-reformed using a commercially available catalyst at two different maximum temperatures, 378°C and 328°C, at various S / C ratios using a steam pre-reforming process that produces a high content of methane. The catalyst was a nickel-based pre-reforming catalyst C11-PR supplied by United Catalysts Corporation. The measured conversions given in Table 3 show that they are at least close to those predicted by the thermodynamic calculations given above. Steam reforming is performed adiabatically in a microreactor system and the gas composition is analyzed online. Note that the experimental setup was not ideal and it is believed to indicate incomplete conversion. A total conversion of at least 97.5% is generally desired, and to ensure this, a suitable residence time on the catalyst is used. All percentages are % by volume, given on a dry basis.

[0043] temperature

example 2-4

[0045] A methane-enriched fuel oil product was further tested for internal reforming of LPG obtained from Victorian, Australia ("Victorian LPG") on SOFC anodes in a typical steam pre-reformer. The composition of Victorian LPG varies from 100% propane to a mixture of propane, butane and / or ethane. The LPG composition used in this work is 93% propane and 7% ethane.

[0046] The test was conducted in a typical fuel processor with 0.6 L of the aforementioned commercial pre-reforming catalyst C11-PR. Select operating conditions so that the methane content of the reformed gas is higher than that traditionally produced by propane and ethane pre-reforming, and remain on the catalyst for a sufficient time to achieve 100% propane and ethane transform. The experimental results are given below, together with the operating conditions. It should be noted that the results are given by the dry weight method.

example 2

[0048] Temperature: 353-380°C, steam / carbon = 1.5

[0049] CH 4 : 48.3

[0050] h 2 : 30.6

[0051] CO 2 : 21.1

[0052] CO: 0.0

[0053] C 3 h 8 : 0.0

[0054] C 2 h 6 : 0.0

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com