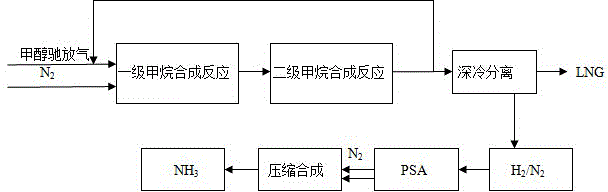

Process for synthesizing LNG (Liquefied Natural Gas) and coproducing liquid ammonia by using methanol purge gas

A methanol degassing and methanol synthesis technology, applied in the preparation/separation of ammonia, petroleum industry, gas fuel, etc., can solve the problems of poor economic benefits and inability to use gas, achieve pure raw materials, reduce compression work loss, and reduce methane The effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The methanol purge gas composition (vol%) in this example is: H276.79, CH42.97, CO3.39, CO24.04, N210.58, CH 3 OH2.1, H 2 O0.13. Methanol release gas volume is 30983Nm 3 / h, temperature 40°C, pressure 5.50MPa.

[0028] The above-mentioned methanol purge gas is directly preheated to 280°C and enters the primary methane synthesis reactor for reaction. The outlet temperature of the primary methane synthesis reactor is 640°C; a part of the outlet gas of the secondary methane synthesis reactor is recycled to the primary methane At the inlet of the synthesis reactor, the molar ratio of the recycle gas to the methanol purge gas entering the primary methane synthesis reactor in this embodiment is 0.3. The outlet composition (vol%) of the secondary methane synthesis reactor is: H242.9, CH48.6, CO5ppm, CO210ppm, N214.3, CH 3 OH7,H 2 O27.2.

[0029] Separation of methane: The purge gas after secondary methane synthesis enters the cryogenic separation device for cryogenic sep...

Embodiment 2

[0033] The methanol purge gas composition (vol%) in this example is: H275.04, CH42.97, CO4.92, CO24.04, N210.80, CH 3 OH2.1, H 2 O0.13. Methanol release gas volume is 30983Nm 3 / h, temperature 40°C, pressure 5.50MPa.

[0034]The above-mentioned methanol purge gas is directly preheated to 280°C and enters the primary methane synthesis reactor for reaction. The outlet temperature of the primary methane synthesis reactor is 650°C; a part of the outlet gas of the secondary methane synthesis reactor is recycled to the primary methane At the entrance of the synthesis reactor, the molar ratio of the recycle gas to the methanol purge gas entering the primary methane synthesis reactor in this embodiment is 0.25. The outlet composition (vol%) of the secondary methane synthesis reactor is: H240.9, CH49.2, CO8ppm, CO210ppm, N215.3, CH 3 OH7.2, H 2 O27.4.

[0035] Separation of methane: The purge gas after secondary methane synthesis enters the cryogenic separation device for cryogen...

Embodiment 3

[0039] The methanol purge gas composition (vol%) in this example is: H276.38, CH42.97, CO5.0, CO24.04, N29.58, CH 3 OH1.9, H 2 O0.13. Methanol release gas volume is 30983Nm 3 / h, temperature 40°C, pressure 5.50MPa.

[0040] The above-mentioned methanol purge gas is directly preheated to 280°C and enters the primary methane synthesis reactor for reaction. The outlet temperature of the primary methane synthesis reactor is 650°C; a part of the outlet gas of the secondary methane synthesis reactor is recycled to the primary methane At the entrance of the synthesis reactor, the molar ratio of the recycle gas to the methanol purge gas entering the primary methane synthesis reactor in this embodiment is 0.4. The outlet composition (vol%) of the secondary methane synthesis reactor is: H240.2, CH49.2, CO6ppm, CO210ppm, N213.3, CH 3 OH6.9, H 2 O30.4.

[0041] Separation of methane: The purge gas after secondary methane synthesis enters the cryogenic separation device for cryogenic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com