Process for directly synthesizing ultra-long single-wall continuous nano carbon tube

A technology of single-walled carbon nanotubes and process methods, applied in the direction of single-walled carbon nanotubes, carbon nanotubes, and oriented carbon nanotubes, can solve the problems of benzene toxicity, environmental pollution, and high carbon content in benzene, and achieve directional Good performance, simple operation, continuous growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

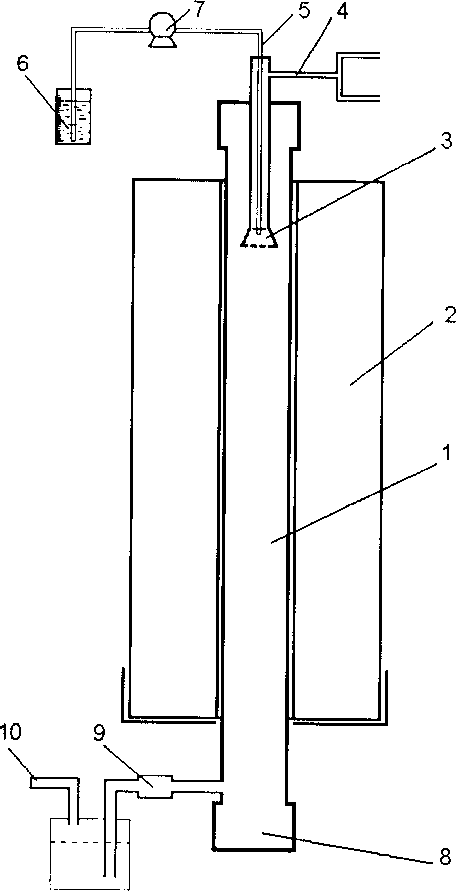

[0012] The equipment main body of the vertical floating catalytic cracking method is a vertical ceramic reaction tube 1 (outer diameter 68mm, inner diameter 58mm, length 1600mm), and this tube is vertically placed in the electric resistance furnace 2 (rated temperature is 1200 ℃, rated power 6KW). The upper part of the reaction vessel is an evaporator 3, including an air inlet 4 and a reaction solution (a mixed solution of n-hexane, ferrocene, and thiophene) inlet 5. The reaction solution 6 is introduced into the evaporator 3 through the liquid micro-flow pump 7 (the evaporation temperature is 150-200° C.) and introduced into the reaction vessel 1 together with the carrier gas (hydrogen) in the form of steam. A product collection bottle 8 , a filter 9 and an exhaust gas outlet 10 are installed below the reaction vessel 1 . The specific operation steps are as follows:

[0013] (1) First pass argon gas at 100ml / min and start to raise the furnace temperature. When it reaches abo...

Embodiment 1

[0021] (1) First flow argon gas at 100ml / min and start to heat up. When it reaches about 1000°C, start to flow hydrogen gas and stop argon gas.

[0022] (2) The temperature is raised to the predetermined reaction temperature (1100° C.), and the reaction solution is introduced to start the preparation of the product. In the reaction solution, n-hexane (C 6 h 14 ) as carbon source, ferrocene (Fe(C 5 h 5 ) 2 , 0.010g / ml) as catalyst, thiophene (G 4 h 4 S, 0.6wt.%) as an additive.

[0023] (3) The reaction solution introduction flow rate is 0.5ml / min, and the hydrogen flow rate is 200ml / min.

[0024] (4) Stop heating after keeping warm for about 60 minutes. Cool with argon (100ml / min) and stop the hydrogen, and collect the product after the temperature drops to room temperature.

[0025] (5) Scanning electron microscopy and transmission electron microscopy were used to detect the microscopic morphology of the product. The product is a 20 cm long filament, which is compos...

Embodiment 2

[0028] (1) First flow argon gas at 100ml / min and start to heat up. When it reaches about 1000°C, start to flow hydrogen gas and stop argon gas.

[0029] (2) The temperature is raised to the predetermined reaction temperature (1150° C.), and the reaction solution is introduced to start the preparation of the product. The reaction solution adopts n-hexane (C 6 h 14 ) as carbon source, ferrocene (Fe(C 5 h 5 ) 2 , 0.020g / ml) as catalyst, thiophene (C 4 h 4 S, 0.4wt.%) as an additive.

[0030] (3) The reaction solution introduction flow rate is 0.5ml / min, and the hydrogen flow rate is 250ml / min.

[0031] (4) Stop heating after keeping warm for about 60 minutes. Cool with argon (100ml / min) and stop the hydrogen, and collect the product after the temperature drops to room temperature.

[0032] (5) Scanning electron microscopy and transmission electron microscopy were used to detect the microscopic morphology of the product. The product is a 20cm long filament, which is comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com