Method for covalence bonding chitosan and base material surface

A substrate surface and covalent bond technology, which is applied in the field of covalently bonded chitosan on the substrate surface, can solve problems such as difficult popularization and application, poor coating stability and durability, and limited interception, and achieve operability Strong, inexpensive, and easy-to-prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

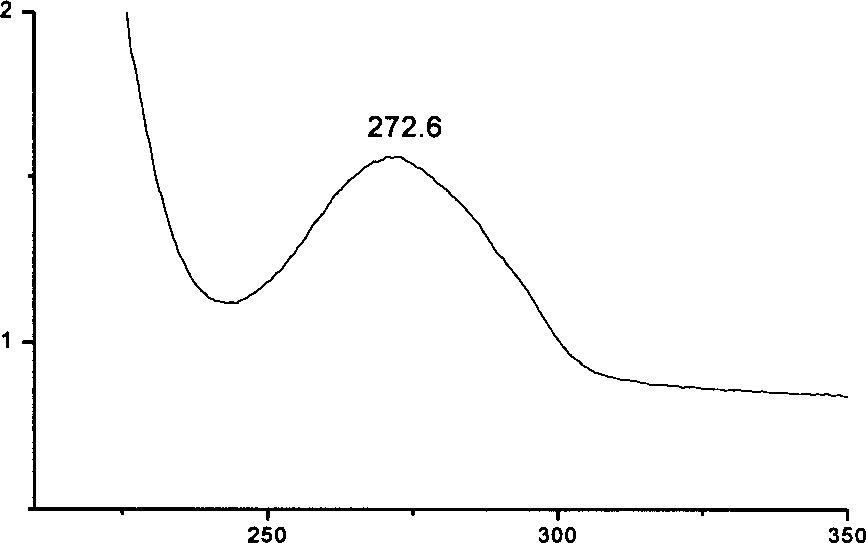

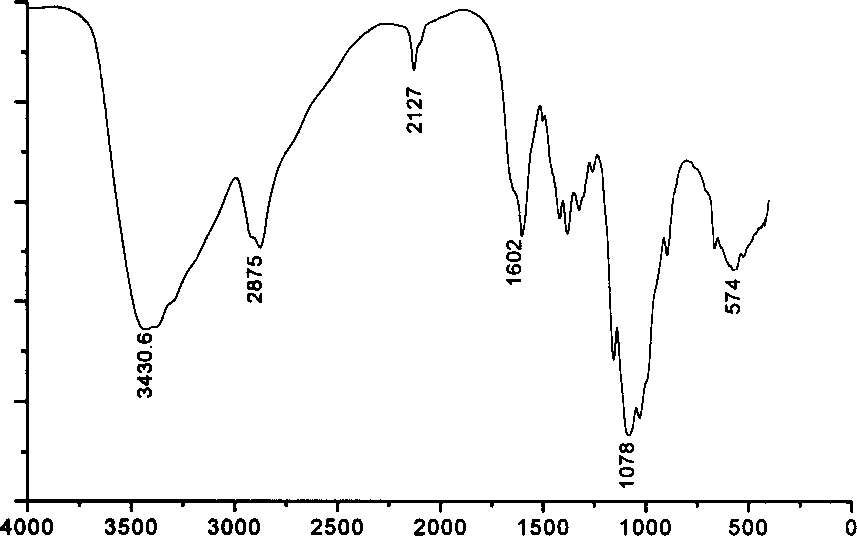

[0014] Preparation of azido chitosan (Az-CS) solution: add 1g chitosan powder, 0.48g DCC and 0.05~0.5g 4-azidobenzoic acid to 100mL solvent, then stir at room temperature for 8h, filter, Fully wash with methanol, filter, and vacuum dry to obtain Az-CS. Then it was dissolved in a mixed solvent of 1% dilute acetic acid and ethylene glycol monomethyl ether (80 / 20 V / V) to form a 0.1% Az-CS solution.

[0015] 1. The method of covalently bonding chitosan on the surface of polylactic acid film: fix chitosan on the surface of polylactic acid (PLA) film, cast 0.1% Az-CS solution on the surface of PLA film, in a brown dryer Let it dry, and the film is 10cm away from an 8W ultraviolet lamp, irradiate for 10min, then wash the film with 5% acetic acid, 0.05NaOH solution and water in sequence, and finally vacuum dry.

[0016] 2. The method of covalently bonding chitosan on the surface of polyurethane: fix chitosan on the surface of polyurethane (PU) (the fixation method is the same as 1), and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com