Process for synthesizing alpha, beta type lead dioxide and leadleaden oxide naon crystal

A technology of lead dioxide and nanocrystals, applied in the direction of lead dioxide, lead oxide, lead red, etc., to achieve the effects of less by-products, lower production costs, and solve environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

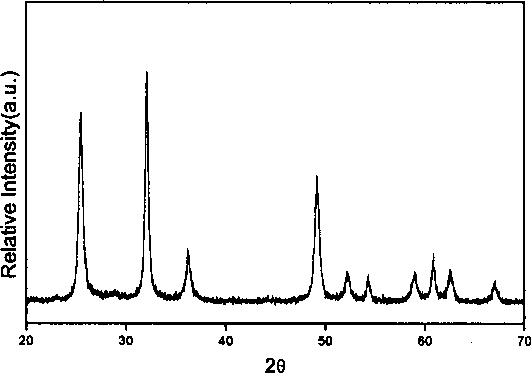

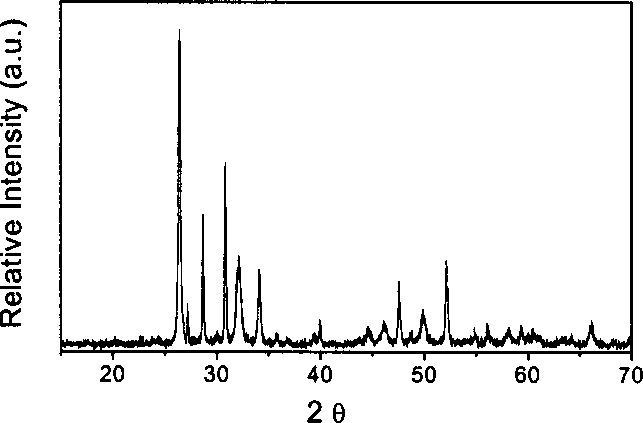

Embodiment 1

[0030] Weigh 5g of analytically pure lead nitrate and dissolve it in 10mL of water, add solid sodium hydroxide to adjust the pH of the solution to 9.0, add 50mL of sodium hypochlorite solution (available chlorine content > 5.5%) after the dissolution is complete, and stir evenly. After reacting at 60°C for 6 hours, the resulting precipitate was filtered, washed, and dried to obtain a brown powder, and the filtrate was treated with 0.01mol·L -1 Potassium chromate solution was tested, and no yellow lead chromate precipitate was observed, indicating that the reaction was carried out completely. Such as figure 1 Shown, product is identified as β-lead dioxide through X-ray powder diffraction; Carry out morphology analysis to β-lead dioxide nanocrystal with transmission electron microscope (TEM), from figure 2 It can be seen that its morphology is rod-shaped, the diameter of the rod is between 10-20nm, the length is 400nm, and the aspect ratio is more than 20. Put the synthesized...

Embodiment 2

[0032] Weigh 3g of analytically pure lead hydroxide in 10mL of water, add 10% sodium hydroxide solution, adjust the pH of the solution to 13.0, add 40mL of sodium hypochlorite solution (available chlorine content > 5.5%) after the dissolution is complete, and stir evenly. After reacting at 30°C for 24 hours, the obtained precipitate was filtered, washed and dried to obtain brown α-lead dioxide powder, and the filtrate was treated with 0.01mol·L -1 Potassium chromate solution was tested, and no yellow lead chromate precipitate was observed, indicating that the reaction was carried out completely. The obtained α-lead dioxide was pyrolyzed at 410° C. for 6 hours according to the method in Example 1 to prepare trilead tetraoxide nanocrystals.

Embodiment 3

[0034] Weigh 5g of analytically pure lead oxide into 10mL of water, add solid sodium hydroxide, adjust the pH of the solution to 10.0, add 50mL of sodium hypochlorite solution (available chlorine content > 5.5%) after the dissolution is complete, and stir evenly. After reacting at 120°C for 2 hours, the obtained precipitate was filtered, washed and dried to obtain brown β-lead dioxide powder, and the filtrate was treated with 0.01mol·L -1 Potassium chromate solution was tested, and no yellow lead chromate precipitate was observed, indicating that the reaction was carried out completely. The obtained β-lead dioxide was pyrolyzed at 430° C. for 4 hours according to the method in Example 1 to prepare trilead tetraoxide nanocrystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com