Non-synchronous motor parameter identification method

An asynchronous motor and parameter technology, which is used in the control of generators, motor control, motor generator control, etc., can solve the problems of large program calculation, complex identification process, and low identification parameter accuracy, so as to improve accuracy and stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

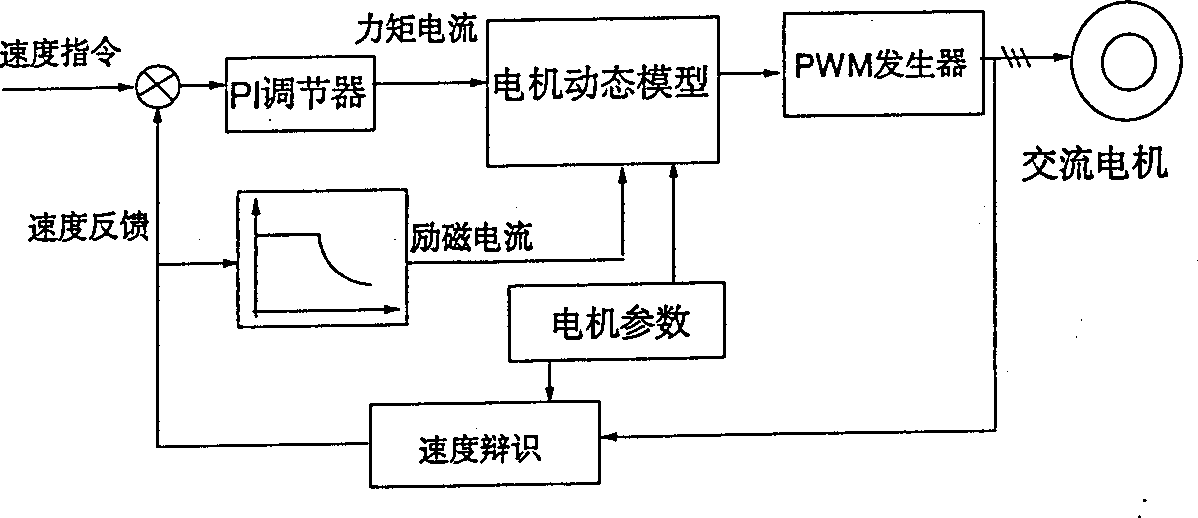

[0034] The method of the present invention is a high-precision off-line identification method that is practical in engineering. The method utilizes the traditional electromechanical test principle, and at the same time considers in detail the conduction voltage drop, switch delay, dead time and The influence of the skin effect, through correct compensation to achieve high accuracy of identification parameters.

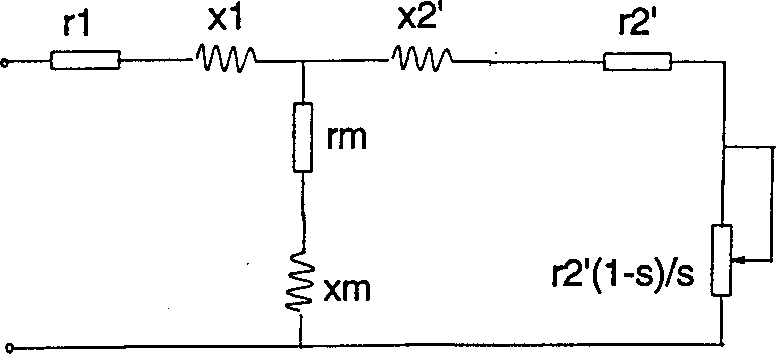

[0035] The method is based on the figure 2 In the steady-state equivalent circuit of the motor shown, the identified parameters are all parameters in the steady-state equivalent circuit.

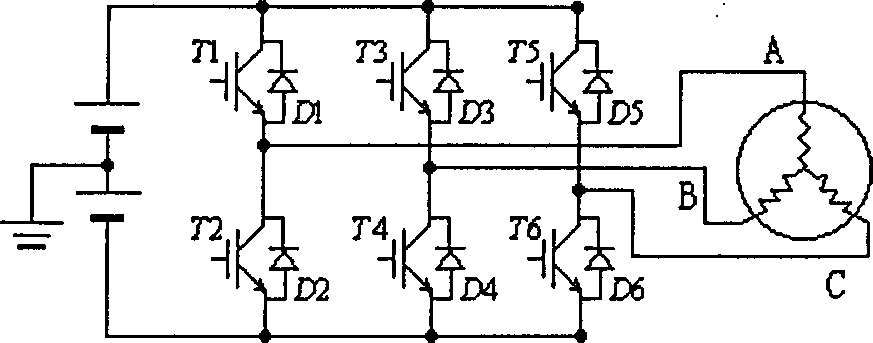

[0036] Such as image 3 As shown, this method is an off-line parameter identification method used in a voltage-type AC-DC-AC frequency conversion speed regulation system. This method includes three processes: stator resistance identification test, short-circuit test and no-load test , the implementation methods of these three steps will be introduced in detail below.

[0037] 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com