Inner-cooling water microcirculation slowly-releasing regulation and control method and its monitoring system

A circulation system and monitoring system technology, applied in control/regulation systems, non-electric variable control, electric components, etc., can solve problems such as corrosion of copper wires, hydrogen use, and difficulty in ensuring the airtightness of supply water pipelines, etc. , to achieve the effect of inhibiting the corrosion of copper and reducing the corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

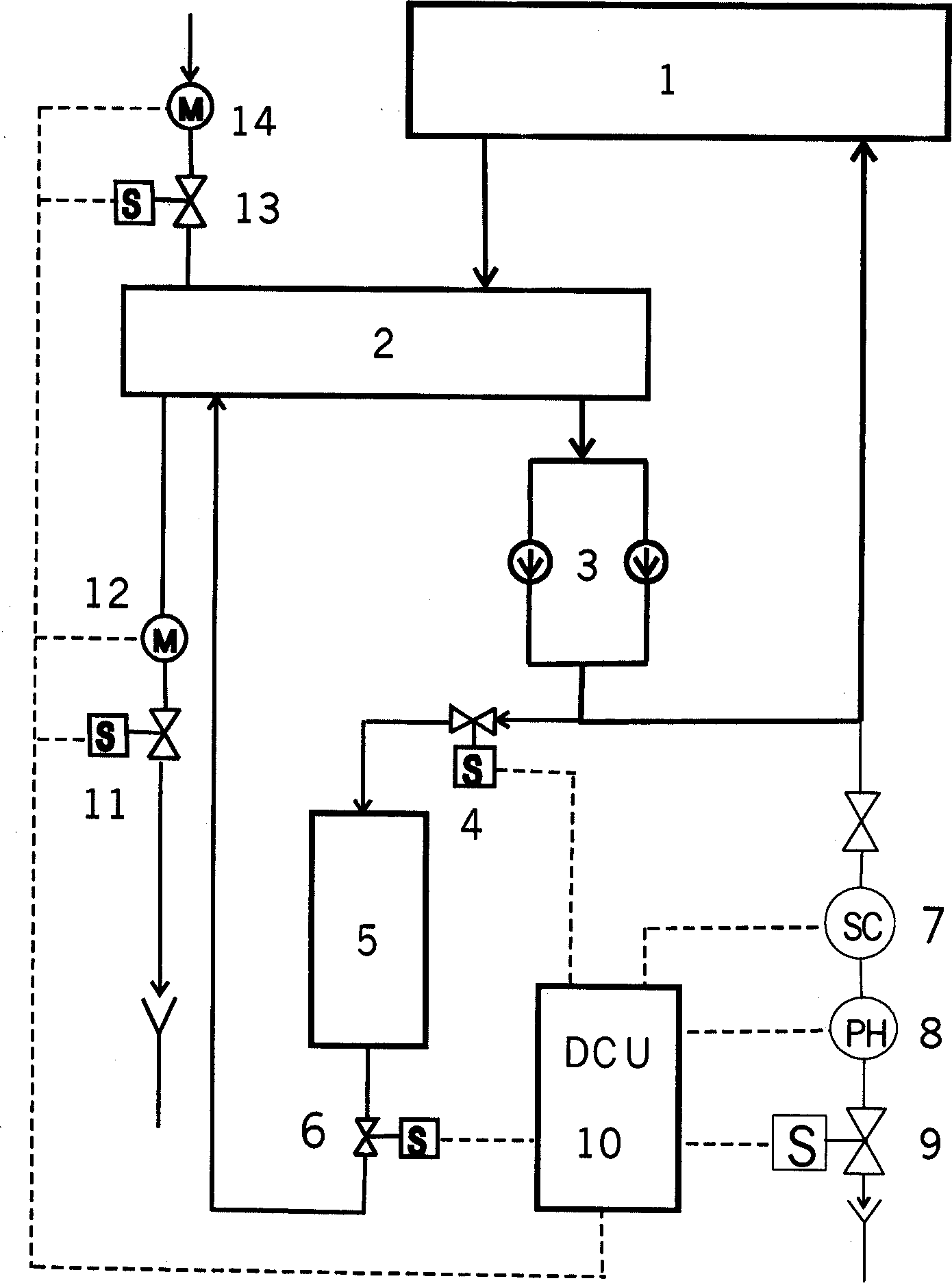

[0010] In the figure: 1. Generator stator winding, 2. Internal cooling water tank, 3. Internal cooling water circulation pump. The measurement and control unit 10 collects the water quality signal of the internal cooling water from the online conductivity meter 7 and the online pH meter 8, and after processing, sends out a control signal to open or close the solenoid valves 4 and 6 to control the commissioning or shutdown of the small mixed bed 5; Or control the opening or closing of solenoid valves 11 and 13 to perform sewage discharge and water replenishment operations; the measurement and control unit 10 collects flow signals from the sewage discharge flowmeter 12 and water replenishment flowmeter 14 and performs water balance adjustment; the measurement and control unit 10 also controls the electromagnetic valve according to the set value. The opening or closing of the valve 9 performs discontinuous water quality detection and control.

[0011] The basic substance for real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com