Adaptive probe device

A technology of probes and microelectronic devices, applied in the field of adaptable probe devices, to achieve reliable testing and enhanced testing functions, improve production efficiency, and reduce size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

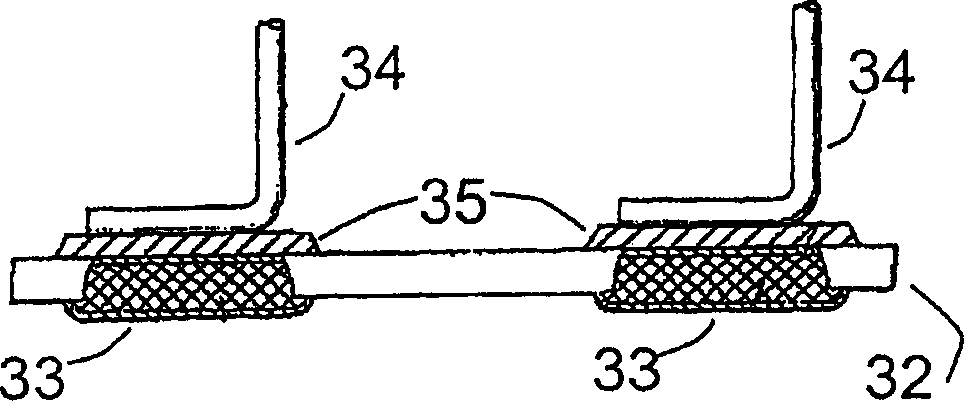

[0052] In accordance with the principles of the present invention, a first preferred embodiment of an adaptable probe is shown in Figure 5 . The disclosed probes allow reliable electrical connections to be made on contact pads of microelectronic devices such as integrated circuits (ICs), flip-bonded chips, passive devices, and chip-scale packages. The probe provides elastic vertical movement of the probe tip 81 in response to a force on the tip. Thus, when the contact pad is urged into contact with the probe tip 81, the mechanical bending of the structure allows the tip to come into contact with the mating contact pad with a force sufficient to cause the probe tip 81 to penetrate the pad on the pad. insulating oxide film. The mechanical flexing of the probes accommodates the height variation of the contact pads in the microelectronic device area, while providing sufficient force on each probe tip to ensure a reliable electrical connection between the tip and the correspondi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com