Continuous torsion-less drawing process of producing steel wire with spiral rib

A spiral rib steel wire, operation production technology, applied in the field of steel wire production technology, can solve the problem of uneven mechanical properties of steel wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

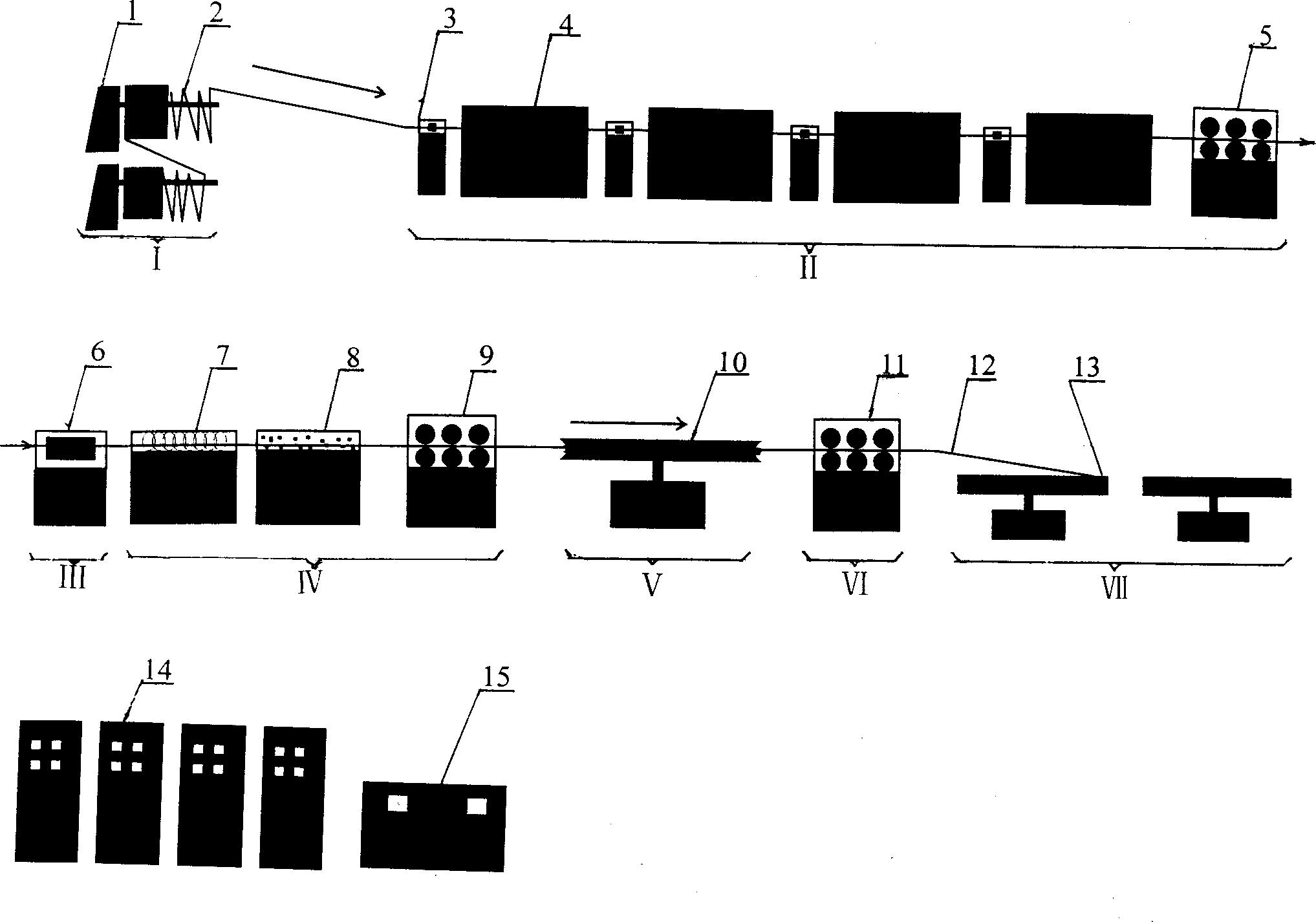

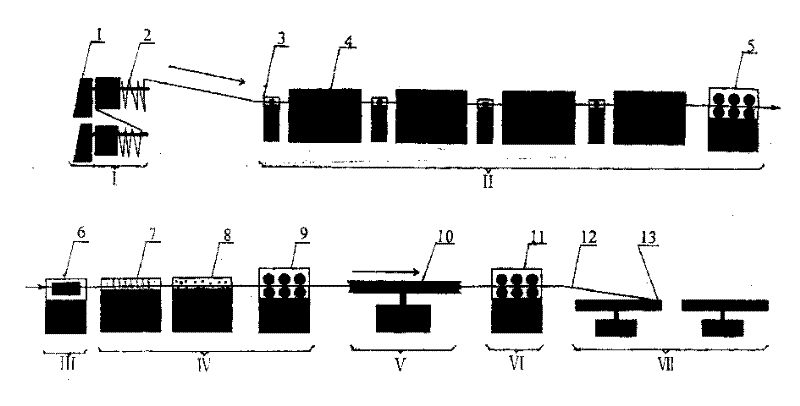

[0018] Send the surface-treated wire rod 2 into the pay-off process I, which is equipped with two support type pay-off racks 1, and the tail of the wire rod 2 produced by online motion on one of the pay-off racks is the same as that on the other pay-off rack. The production wire rod 2 is docked; the butted wire rod 2 enters the multi-pass cold drawing plastic deformation process II, and the wire drawing equipment 4 in this process performs multi-pass cold drawing plastic deformation on the wire rod 2, and the stress adjustment device 3 Track and adjust the stress changes between different molds or caused by small changes in mold size. In order to avoid affecting the toughness of the wire due to plastic deformation and heating, this process is also equipped with water cooling facilities for wire drawing die sleeves; the water-cooled wire passes through the straightener 5 Entering the rotational plastic deformation process III, the rotor core of the rotational deformer 6 is embed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com