Oven-baked french fries having extended hold time

A French-style, french fries technology, applied in food coating, food forming, application, etc., can solve problems such as poor taste and texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069]When the covered par-fries are prepared for food retail use, the par-fries are cooked in an oven, preferably for a time of about 0.5 to about 10 minutes at a temperature of about 325°F ( 162°C) to about 600°F (316°C). For par-fries that are substantially single-covered, such finish baking is performed in a forced-air convection oven or a hot-air impingement oven at an oven temperature of about 350°F (176.7°C) to about 500°F (260°C). ) is preferably from about 0.5 to about 5.0 minutes, preferably from about 1.0 to 4.0 minutes, more preferably from about 1.5 to about 3.0 minutes. Alternatively, French fries can also be finished in the user's home oven. Since most home users don't have their own deep fryer, they want to be able to make good quality French Baked French Fries. Covered par-fries can be prepared in a conventional home oven to prepare French-style French fries of the present invention with a baking time of 15 minutes or less, preferably less than or equal to a...

Embodiment 1

[0102] Raw Russet potato strips were sorted, washed and peeled. Cut the fries into shoestring shapes and blanch them in hot water at 165°F (79.3°C) for 3.5 minutes. Spray a solution of salt, dextrose, and sodium acid pyrophosphate over potato strips. The chips are then pre-dried at 165°F (73.8°C) for a period of time to reduce the moisture content of the chips by 10%.

[0103] After pre-drying, the french fries were dipped in the mulch tank to apply the mulch to the french fries. The properties of the starch and solid compositions in the covering are listed in Tables 1 and 2 below, respectively.

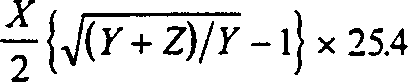

[0104] The starch-based covering was 41.5% solids and the remainder water. The pick-up rate of the cover paste is 18%, resulting in a theoretically calculated shell thickness of 0.65 mm.

[0105] French fries are then deep-fried at 375°F (190.6°C) to about 60% humidity. The par-fries were frozen in a forced-air freezer at -15°F (-26.1°C) for 20 minutes. After freezing, the prod...

Embodiment 2

[0114] Commercially available par-fries at 64% humidity were immersed in an aqueous solution of a starch-based coating. The composition of the covering solids is listed in Table 3.

[0115] 20% of the mulch is solids and the rest is water. Drain the moisture from the covered chips. (Cover) The pick-up rate is about 10%, and the resulting cover layer is about 0.15mm thick. The drained chips were fried in oil at 320°F (160.0°C) to a final bulk moisture of 47%, and the product was frozen in a forced-air freezer at -15°F (-26.1°C) for 20 minutes. Par-fries were cooked at 395°F (190.5°C) for 2 minutes and 16 seconds in a high velocity air impingement oven. After refining, salt and oil are applied to French fries. Hold for a total of 14 minutes using the hold mode described in the analysis section here. French fries have a fat mass of 15% and moisture of 37.1%, with a maintained texture value of 237.

[0116] table 3

[0117] Ingredient %...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com