Bag dust collector for coal burning boiler and furnace

A bag-type dust collector and coal-fired boiler technology, applied in the field of air pollution control and bag-type dust collector, can solve the problems of high manufacturing and installation costs, many consumable materials, and filter bag burning, and achieve low manufacturing and installation costs. The effect of high reaction sensitivity and low consumption of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

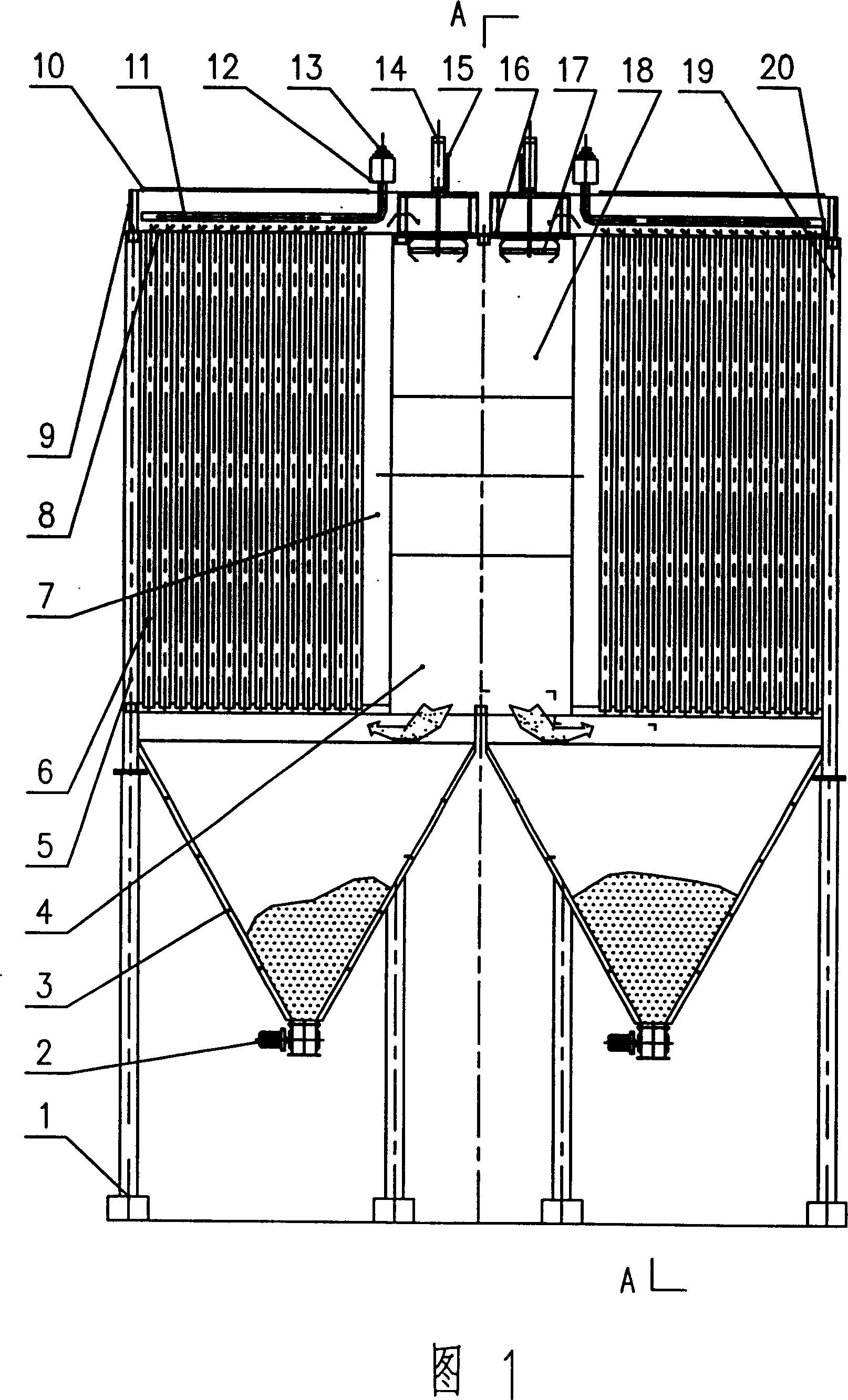

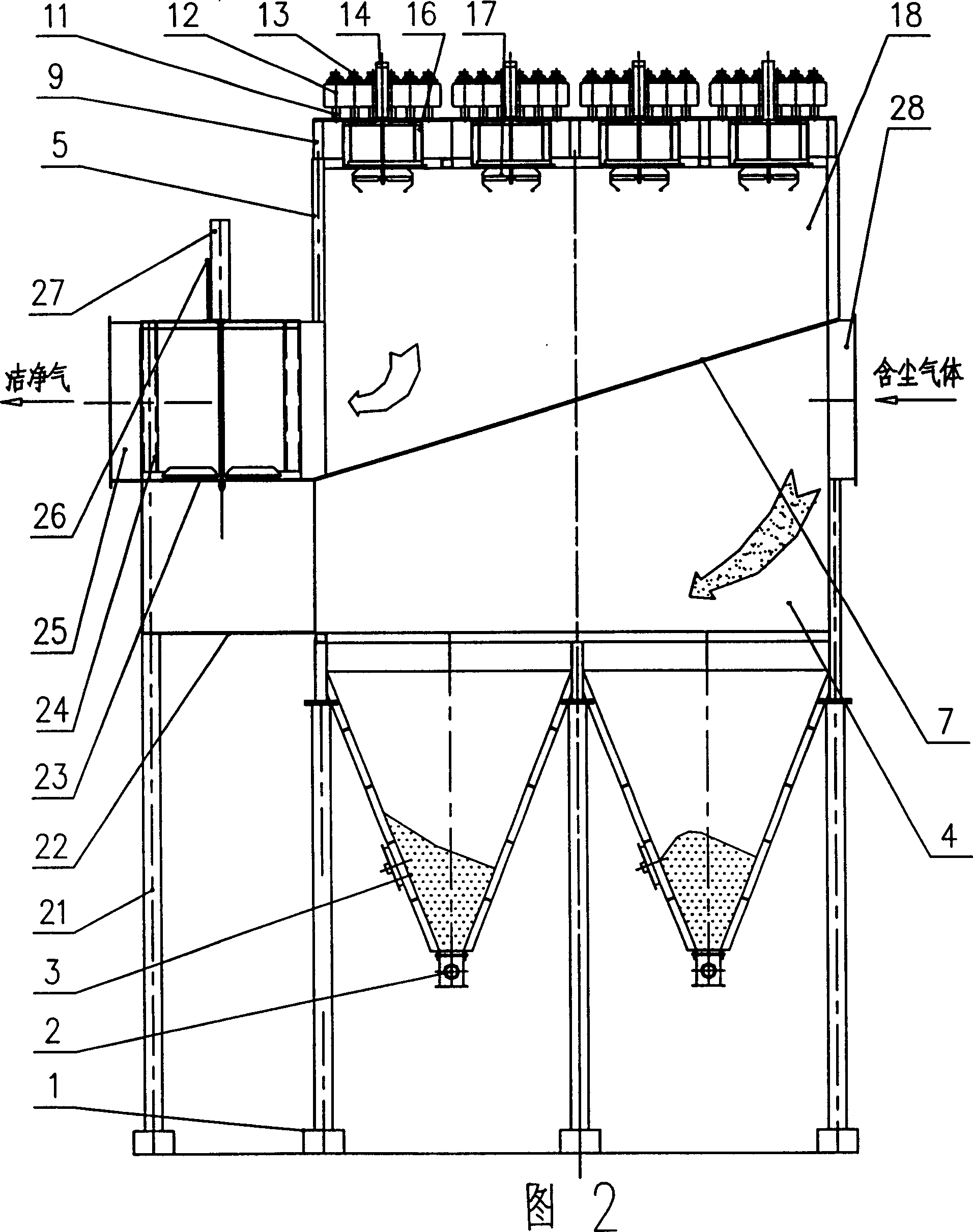

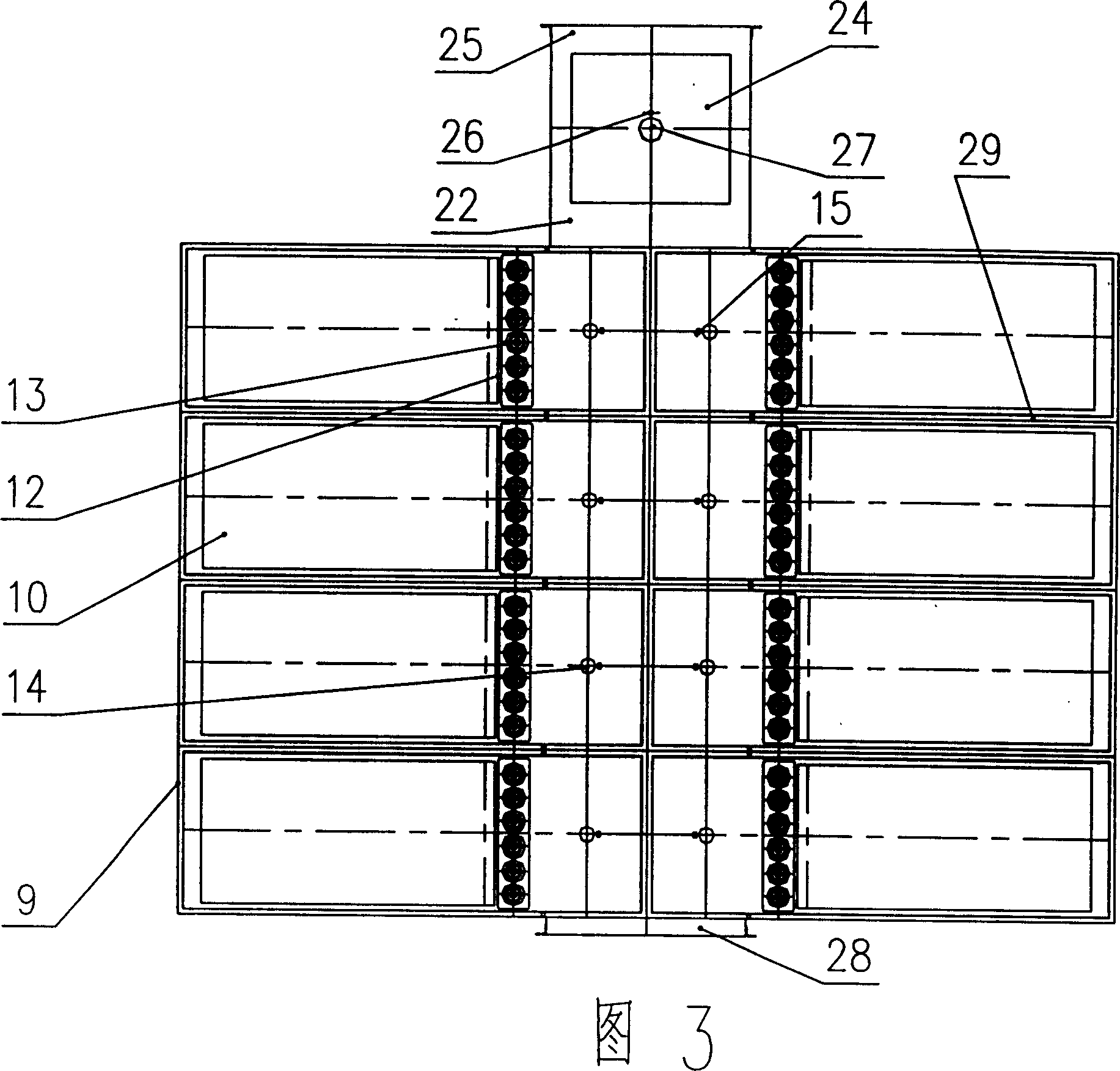

[0024] The bag filter used for the circulating fluidized bed coal-fired boiler with a power of 24.5Mw (35T / h), the overall dimensions are: length × width × height = 9300mm × 9300mm × 13700mm, the maximum flue gas treatment volume is 105000m 3 / h(69530 Nm 3 / h), the equipment structure is shown in Figure 1-Figure 4, including bracket 1, unloader 2, ash hopper 3, air inlet channel 4, left middle box 5, filter bag and filter cage 6, middle partition 7. Flower plate 8, upper box body 9, cover plate 10, blowing pipe 11, air bag 12, pulse valve 13, offline valve cylinder 14, offline valve travel switch 15, offline valve body 16, offline valve plate 17, Air outlet channel 18, right middle box 19, blowing pipe support 20, air outlet 25, air inlet 28, bag chamber partition 29, air control valve 30 for off-line valve, pneumatic circuit for opening and closing the control valve, air control The control circuit of the valve also includes extension box pillar 21, extension box 22, bypass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com