Apparatus for growing crystal by repeating adding material and method thereof

A technology for growing crystals and feeding tubes, which is applied in the directions of polycrystalline material growth, crystal growth, single crystal growth, etc., and can solve problems such as the application of limited and repeated feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The device and method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

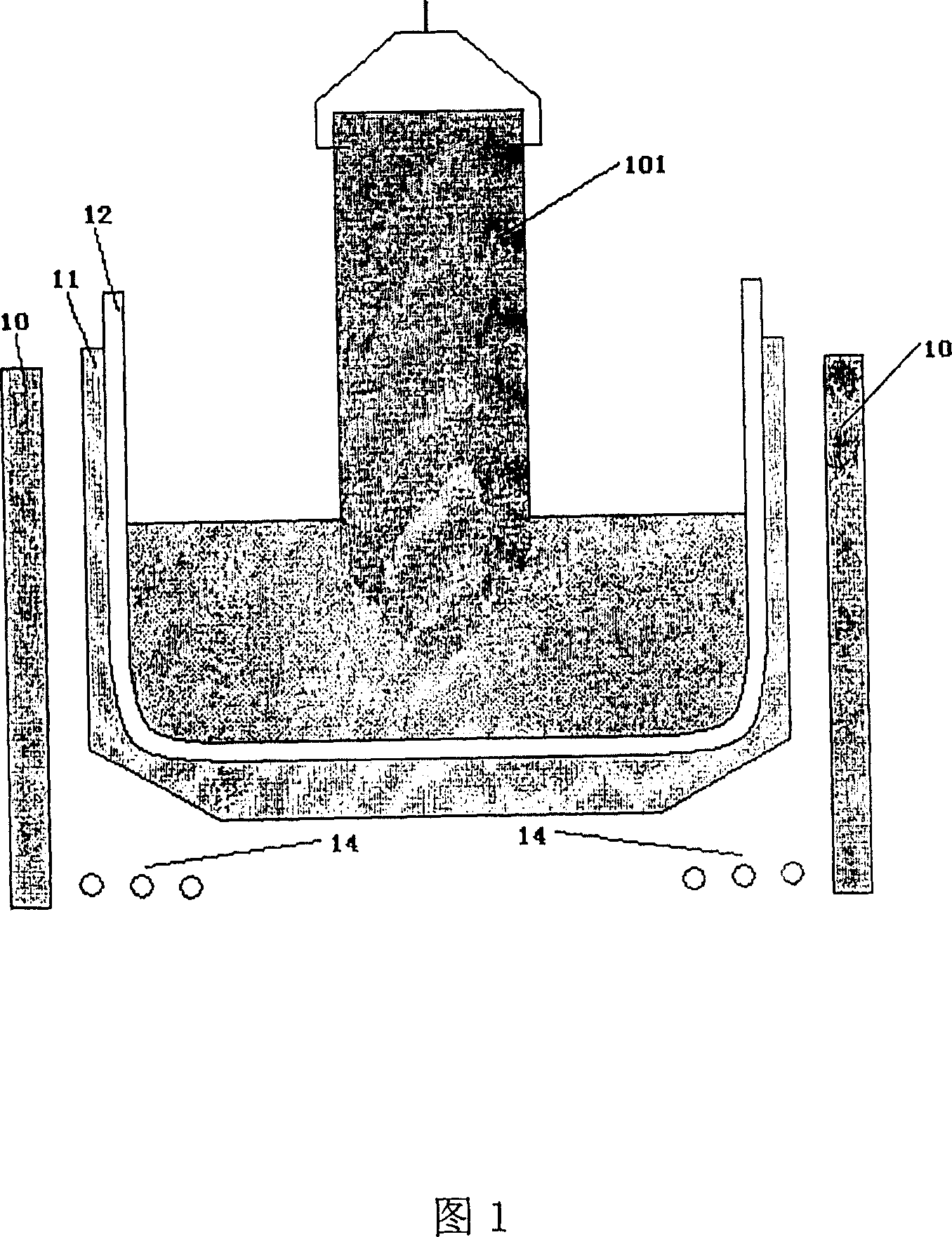

[0033] Fig. 1 shows that in the prior art, the molten material crucible 12 is placed in the graphite crucible 11 in the graphite heater 10. A whole rod-shaped growth material 101 is used to repeatedly feed into the melting material crucible 12 . Part of the growth raw material has been melted in the melting material crucible 12 to form a melt 13 . Below the graphite crucible 11, there are heater connection lines 14 between the graphite heaters 10.

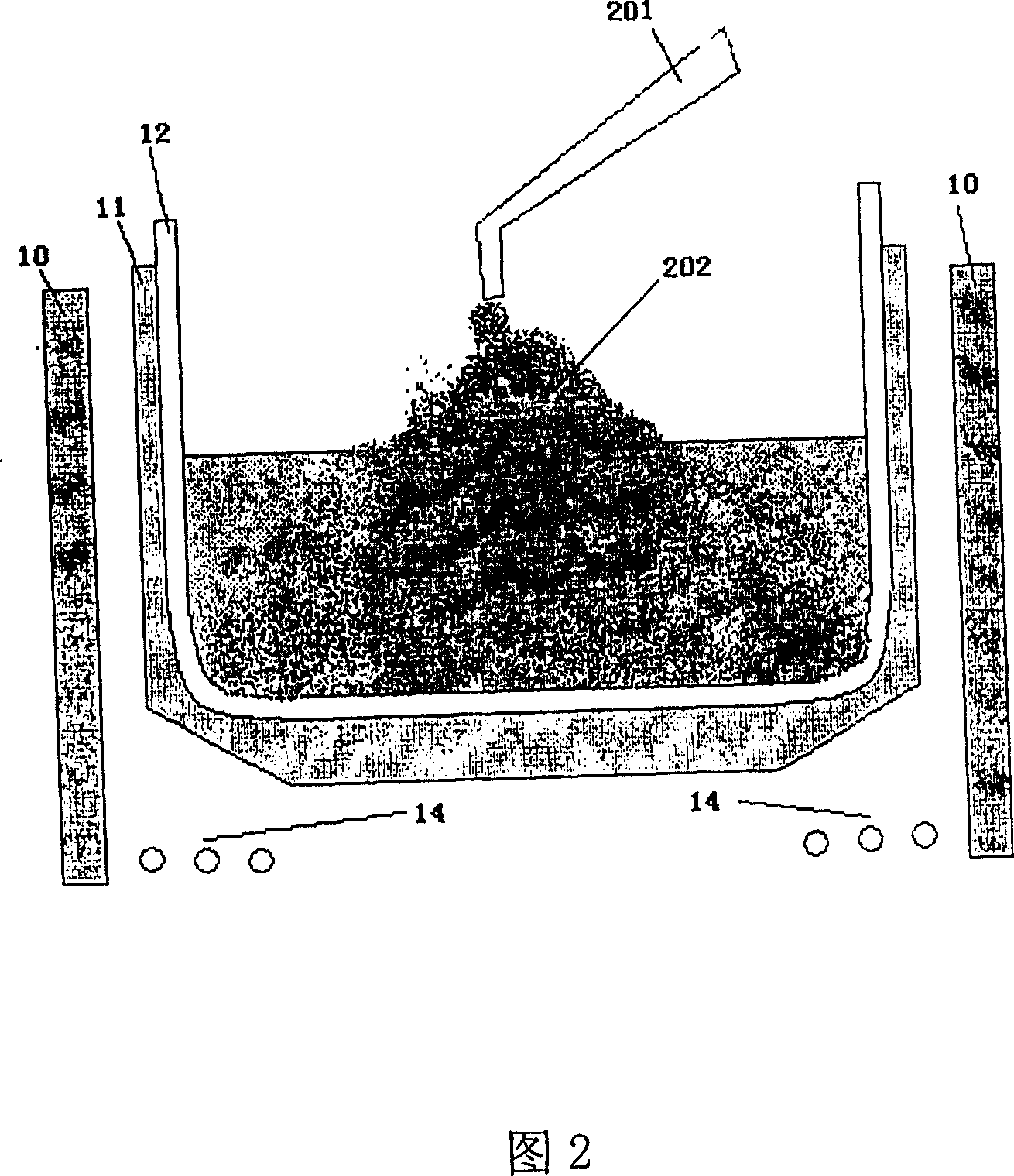

[0034] FIG. 2 shows that in the prior art, a feeder 201 is used to repeatedly feed granular or small block growth raw materials 202 into the melting crucible 12 . Wherein the granular growth material 202 is a particle with a diameter of several millimeters.

[0035] FIG. 3 shows that all the growth raw materials in the melting material crucible 12 are melted into a melt, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com