Method for preparing environment friendly catalyst

An environment-friendly and catalytic technology, which is applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problems of non-reusable, high catalyst cost, and unsatisfactory service life, and achieve simple production, low cost, and easy The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

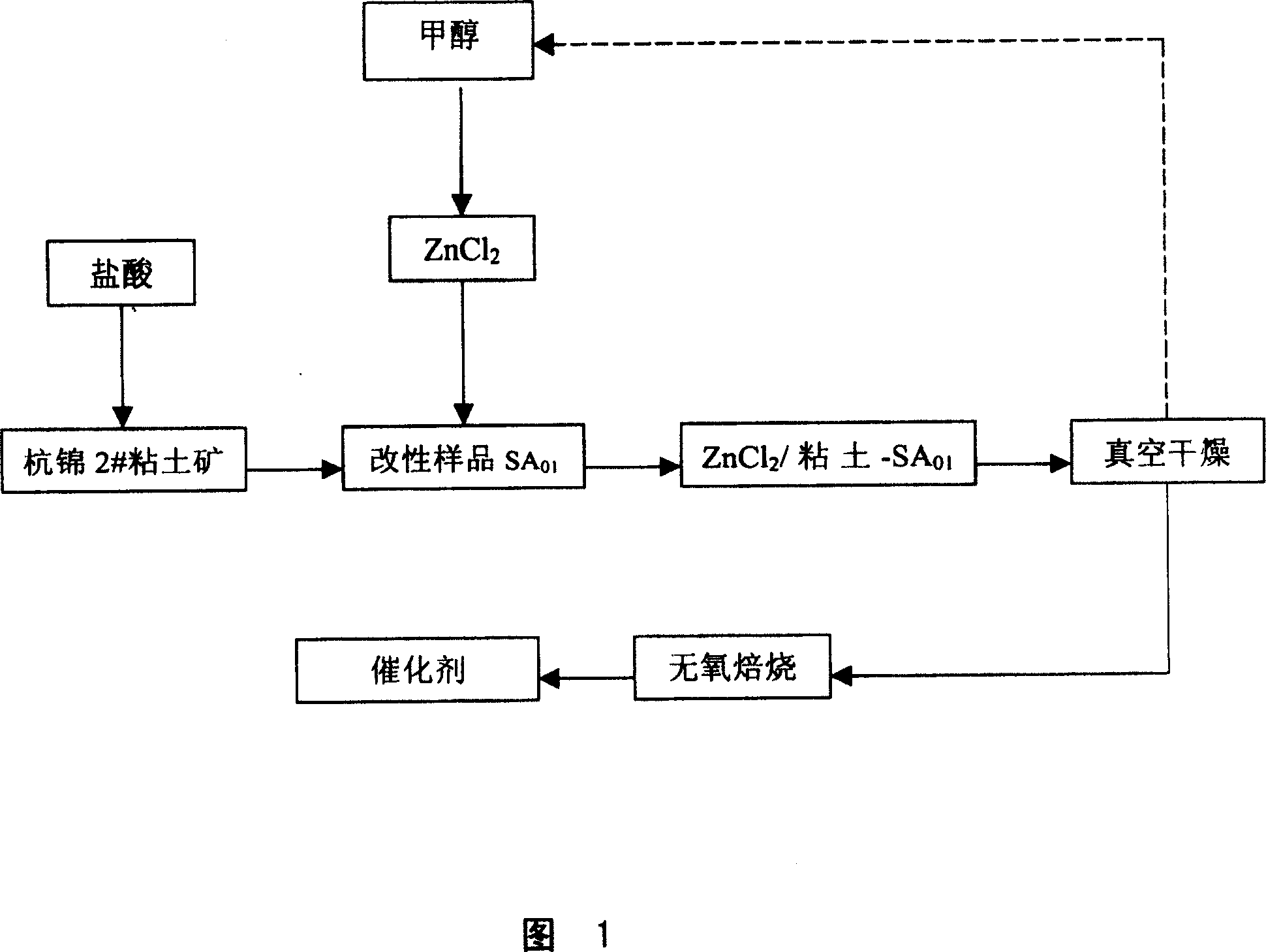

[0007] As shown in Figure 1, take Hang Jin 2 # Add 1000g of clay raw soil ore, add 2500g of hydrochloric acid with a concentration of 10%, boil slightly at 105°C, stir for 1h, wash with water until pH = 6, filter with suction, dry the filter cake at 105°C, roast at 300°C for 2h, cool to room temperature to obtain 1000 g clay-SA 01 . Then 135gZnCl 2 Add 1000ml methanol to get ZnCl 2 methanol solution. Take 1000g Clay-SA 01 As a carrier, with the above ZnCl 2 The methanol solution was mixed and impregnated for 26 hours, and dried in vacuum at 80°C for 4 hours to obtain ZnCl 2 / clay-sa 01 Solid sample, recovered methanol, in N 2 Under gas protection, calcination at 280°C for 4h, N 2 Cool to room temperature in the atmosphere to make 1135g ZnCl 2 / clay-sa 01 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com