Four-axle linked digital controlled processing post processing method and its control system

A post-processing and four-axis linkage technology, which is applied in the general control system, control/regulation system, program control, etc., can solve the problem of uneven cutting speed of tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

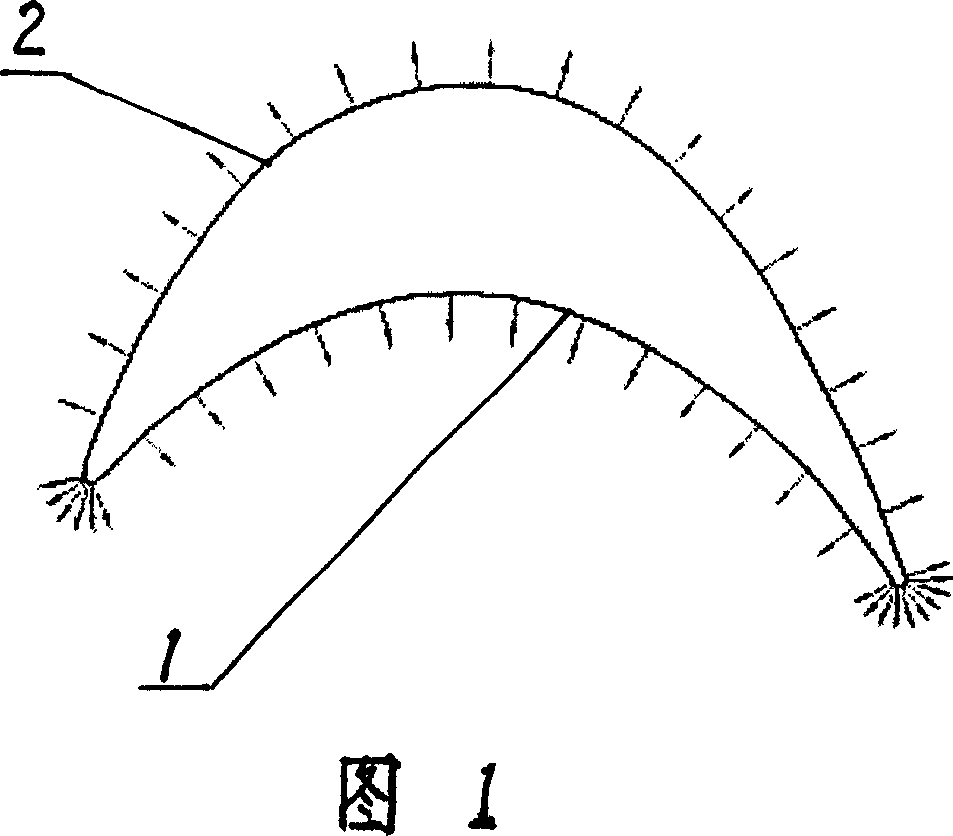

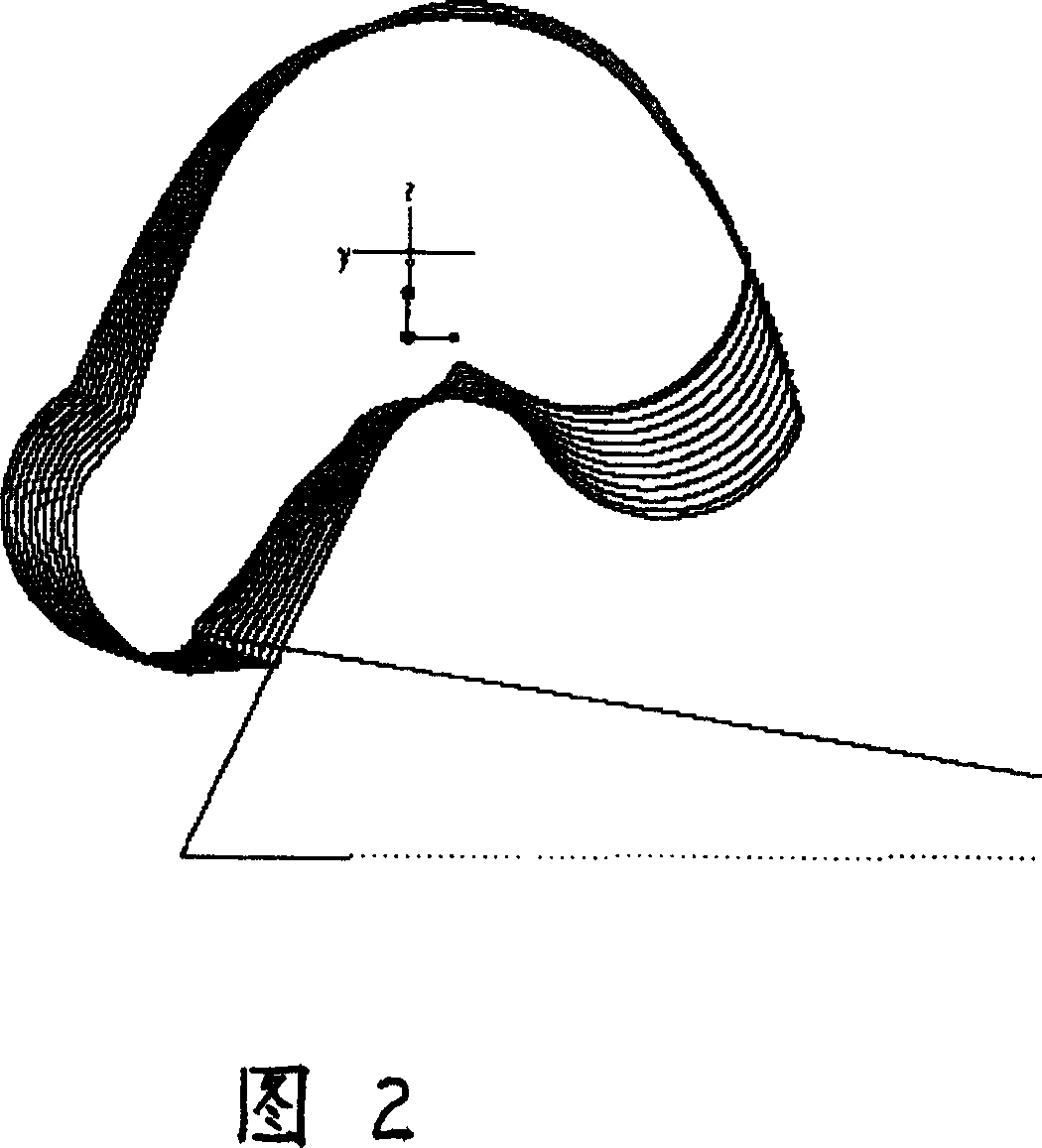

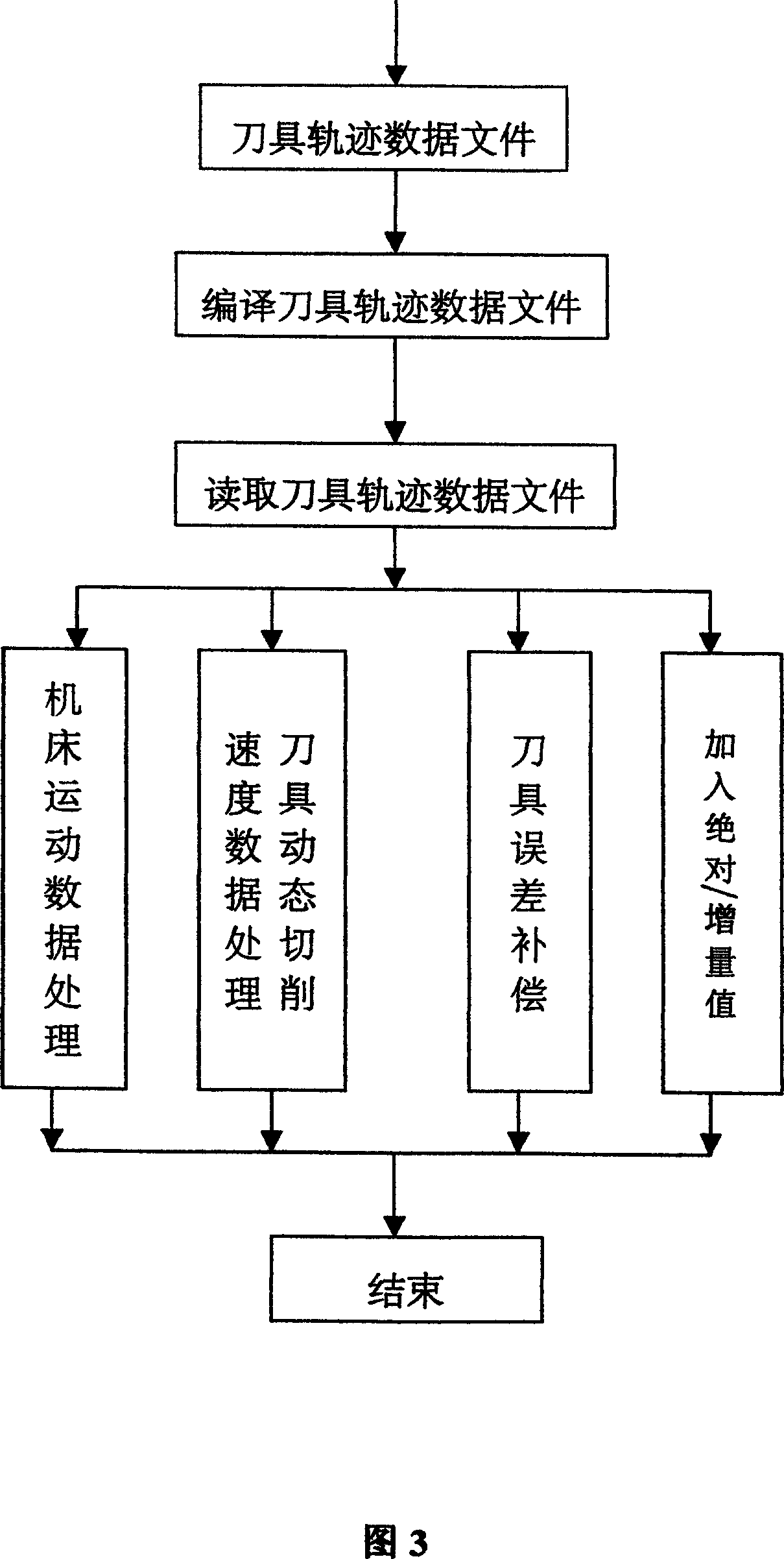

[0045] As shown in FIG. 3 , it is a flow chart of the post-processing method of the present invention. Now take the NC machining of steam turbine blade profile as an example to illustrate the specific implementation process of the present invention: First, engineers and technicians use CAM software, such as Pro / E, to compile corresponding blade processing programs according to the processing technology requirements. The corresponding tool path data file is generated by the CAM software, and its suffix is NCL, that is: the blade surface processing program code, see Figure 4, and then the programmed computer executes the program command, and executes the tool path data file in the following order deal with:

[0046] First compile the tool path data file, such as: compile a line of instructions in the tool path data file into the following tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com