Method and device for maching longitudinal edges of metal workpieces

A technology for longitudinal edges, metal workpieces, applied in the direction of workpieces, metal processing equipment, manufacturing tools, etc., to achieve the effect of increasing the feed rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

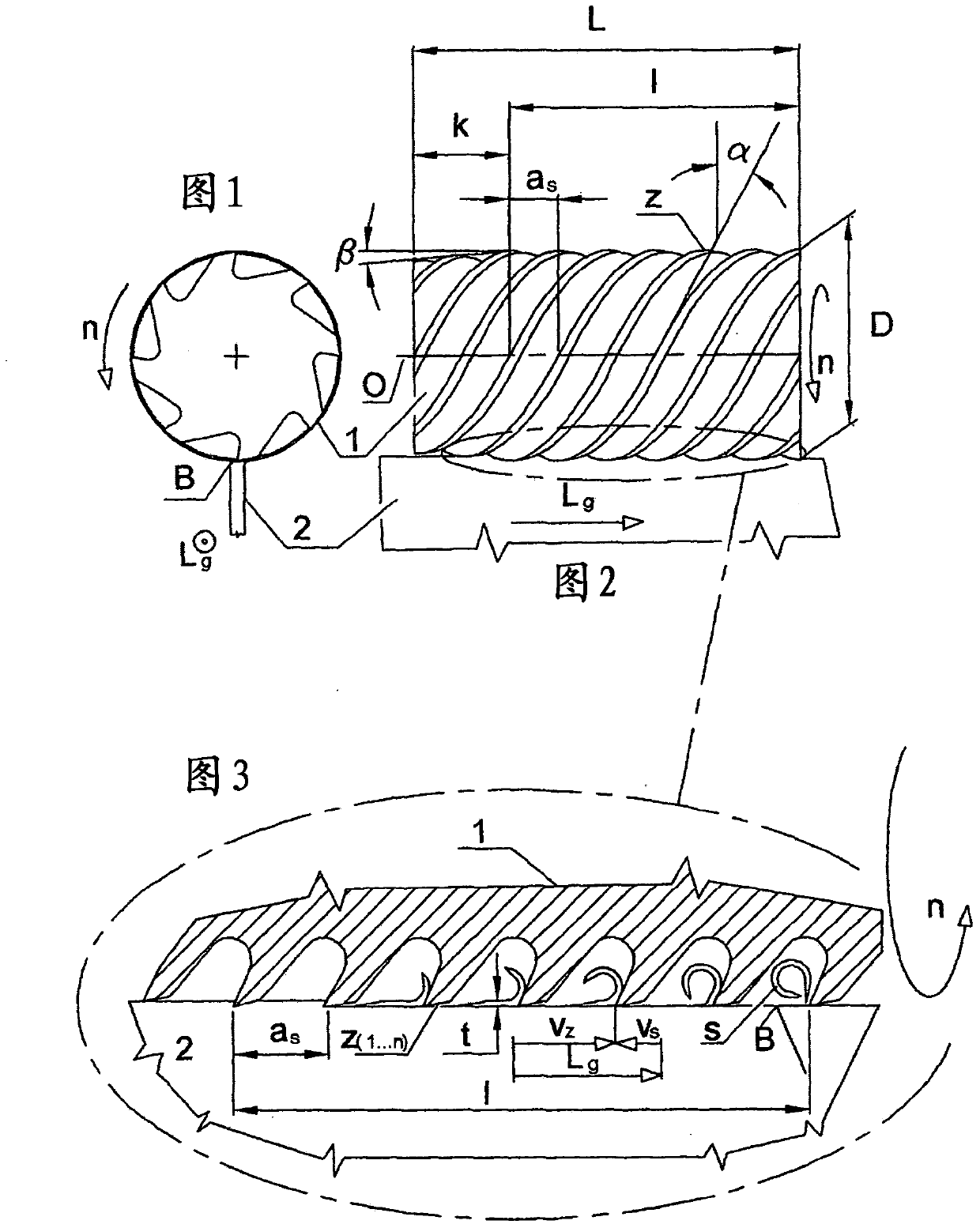

[0019] exist figure 1 A circumferential milling cutter 1 according to the invention and a workpiece 2 are schematically shown in front view.

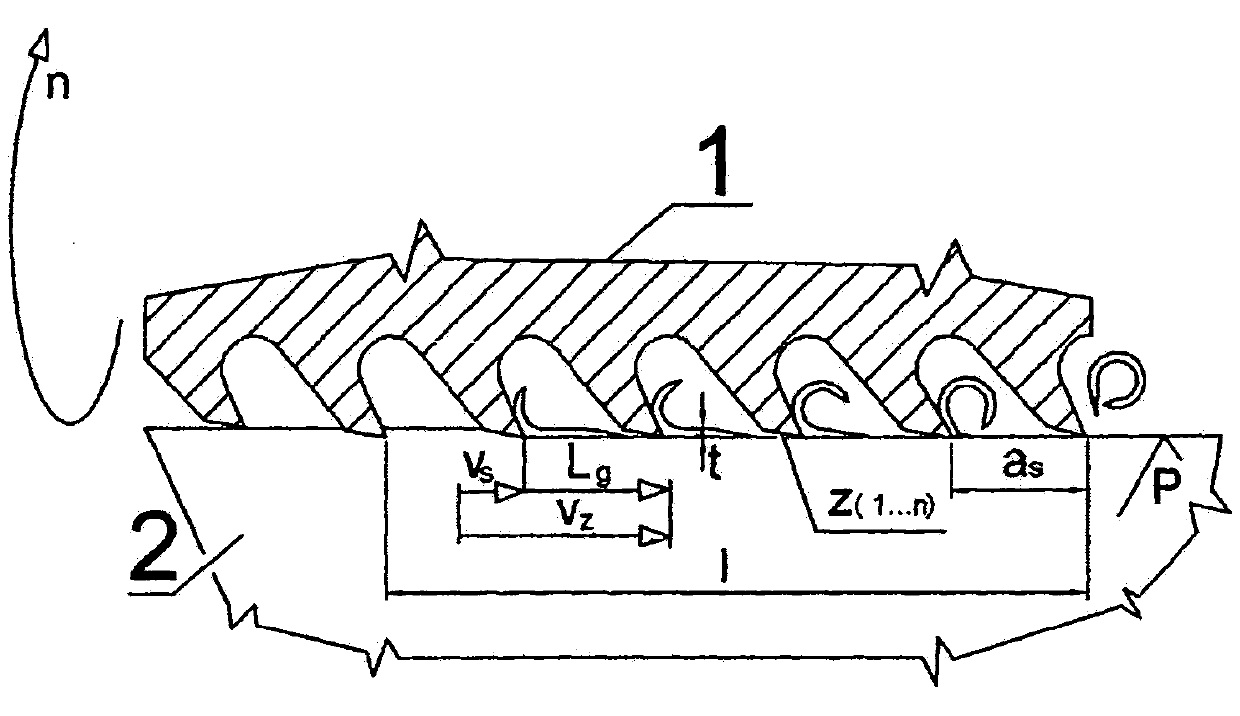

[0020] figure 2 shown in a schematic top view at figure 1 A circumferential milling cutter 1 and a workpiece 2 according to the invention are shown in FIG. The axis of rotation O of the cylindrical peripheral milling cutter 1 is arranged parallel to the machining surface B in such a way that all helically formed cutting edges z interact with the machining surface B over a length l at the same time. The cutting edges are each multi-linear in such a way that they have a helix angle α such that a uniform tooth distance a exists between the individual cutting edges z. s . Circumferential milling cutter 1 in direction of feed L g In the region of one side of the length k, the angle β is conical in order to ensure a smooth action of the cutting edge from the non-cutting state.

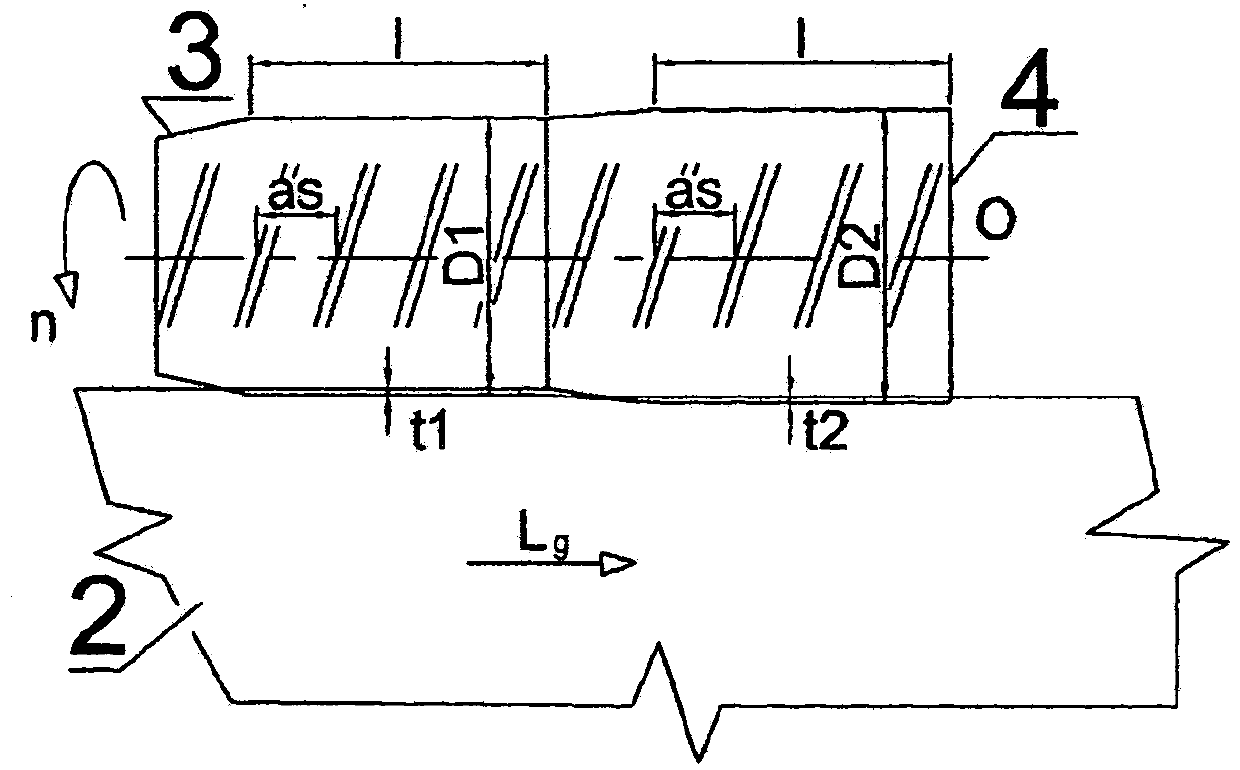

[0021] The circumferential milling cutters each comprise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com