A cutting construction method for high-strength rock formation mountain tunnels

A construction method and high-strength technology, which can be used in tunnels, earthwork drilling, mining equipment, etc., and can solve problems such as unsuitable mountain tunnel hole cutting technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be clearly and completely described below.

[0041] In order to solve the above problems, the present invention provides a cutting construction method for high-strength rock formation mountain tunnels.

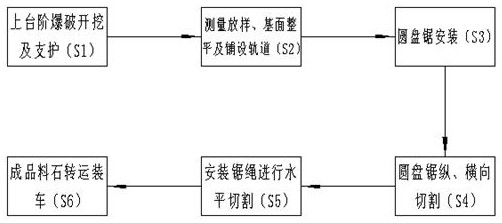

[0042] In order to achieve the technical purpose, the technical solution of the present invention is: a high-strength rock formation mountain tunnel cutting construction method, characterized in that it includes the following steps:

[0043] S1: Set low-velocity explosives on the rock mass to blast the rock mass, and dig out the waste residue generated by the blasting after blasting, and set up anchor bolts to hang the net and spray concrete for initial support, and at the same time strengthen monitoring and measurement work to ensure Surrounding rock stability and construction safety;

[0044] S2: after the blasting in step S1, the lower step rock mass is leveled, and a track is laid on it;

[0045] S3: After the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com