Coagulant for wet spray material and its using method

A wet spray and coagulant technology, applied in the field of coagulants, can solve the problems of coagulation and coagulation effect, inability to thicken and inconspicuous spray materials of polyacrylate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

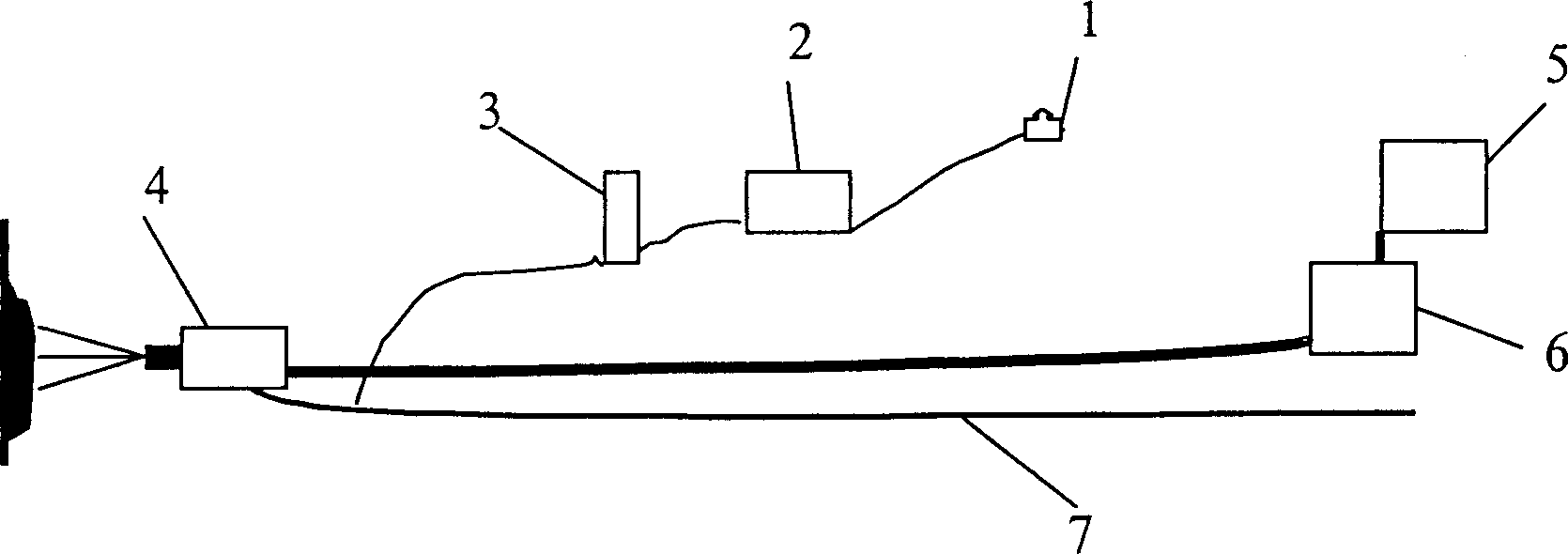

Image

Examples

Embodiment 1

[0028] Example 1: By weight, 5 parts of aluminum dihydrogen phosphate and 2 parts of magnesium chloride were added to 93 parts of water, and stirred to dissolve it into an aqueous solution. As the coagulant of the injection material with sodium polyacrylate as the water reducing agent, its addition is 0.1% of the weight of the injection material. The coagulant has a very good coagulation-accelerating effect, and can make the injection material thicken and lose fluidity within 10 seconds.

[0029] Table 1 shows other performance indicators of the injection material using the coagulant of this example, including the conditions of baking at 110°C for 24 hours and at 1450°C for 3 hours. It can be seen from Table 1 that the coagulation accelerator of the present invention not only has a very good coagulation acceleration effect, but also other performance indicators of the injection material are also excellent.

Embodiment 2

[0030] Example 2: By weight, 10 parts of aluminum dihydrogen phosphate and 5 parts of magnesium chloride were added to 85 parts of water, and stirred to dissolve it into an aqueous solution. As the coagulant of the injection material with sodium polyacrylate as the water reducing agent, its addition is 0.1% of the weight of the injection material. The coagulant has a very good coagulation-accelerating effect, and can make the injection material thicken and lose fluidity within 5 seconds.

[0031] Table 1 shows other performance indicators of the injection material using the coagulant of this example, including the conditions of baking at 110°C for 24 hours and at 1450°C for 3 hours. It can be seen from Table 1 that the coagulation accelerator of the present invention not only has a very good coagulation acceleration effect, but also other performance indicators of the injection material are also excellent.

Embodiment 3

[0032] Example 3: By weight, 30 parts of aluminum dihydrogen phosphate and 4 parts of magnesium chloride were added to 66 parts of water, and stirred to dissolve it into an aqueous solution. As the coagulant of the injection material with sodium polyacrylate as the water reducing agent, its addition amount is 0.1% of the injection material. The coagulant has a very rapid coagulation effect, which can make the spray material thicken and lose fluidity within 3 seconds, and become a hardened solid.

[0033] Table 1 shows other performance indicators of the injection material using the coagulant of this example, including the conditions of baking at 110°C for 24 hours and at 1450°C for 3 hours. It can be seen from Table 1 that the coagulation accelerator of the present invention not only has a very good coagulation acceleration effect, but also other performance indicators of the injection material are also excellent.

[0034] performance

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com