Relaxation type blasting method and protection cover structure for blasting

A technology of tension and shielding, which is applied in the direction of blasting, discharge machinery, earthwork drilling and mining, etc., can solve the problems of increasing blasting noise, train derailment, alarming, etc., reduce blasting noise and blasting vibration, and shorten the cutting operation time The cycle and the effect of small accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below with reference to the drawings.

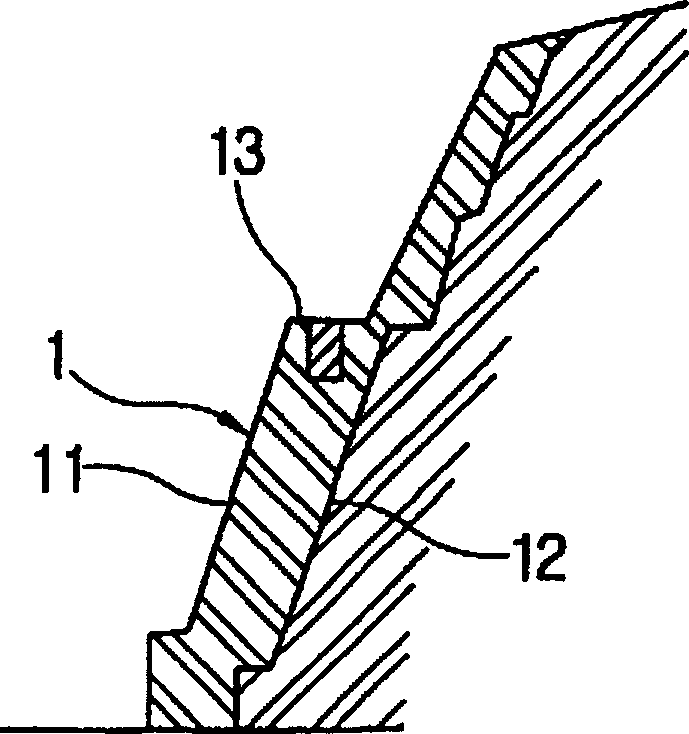

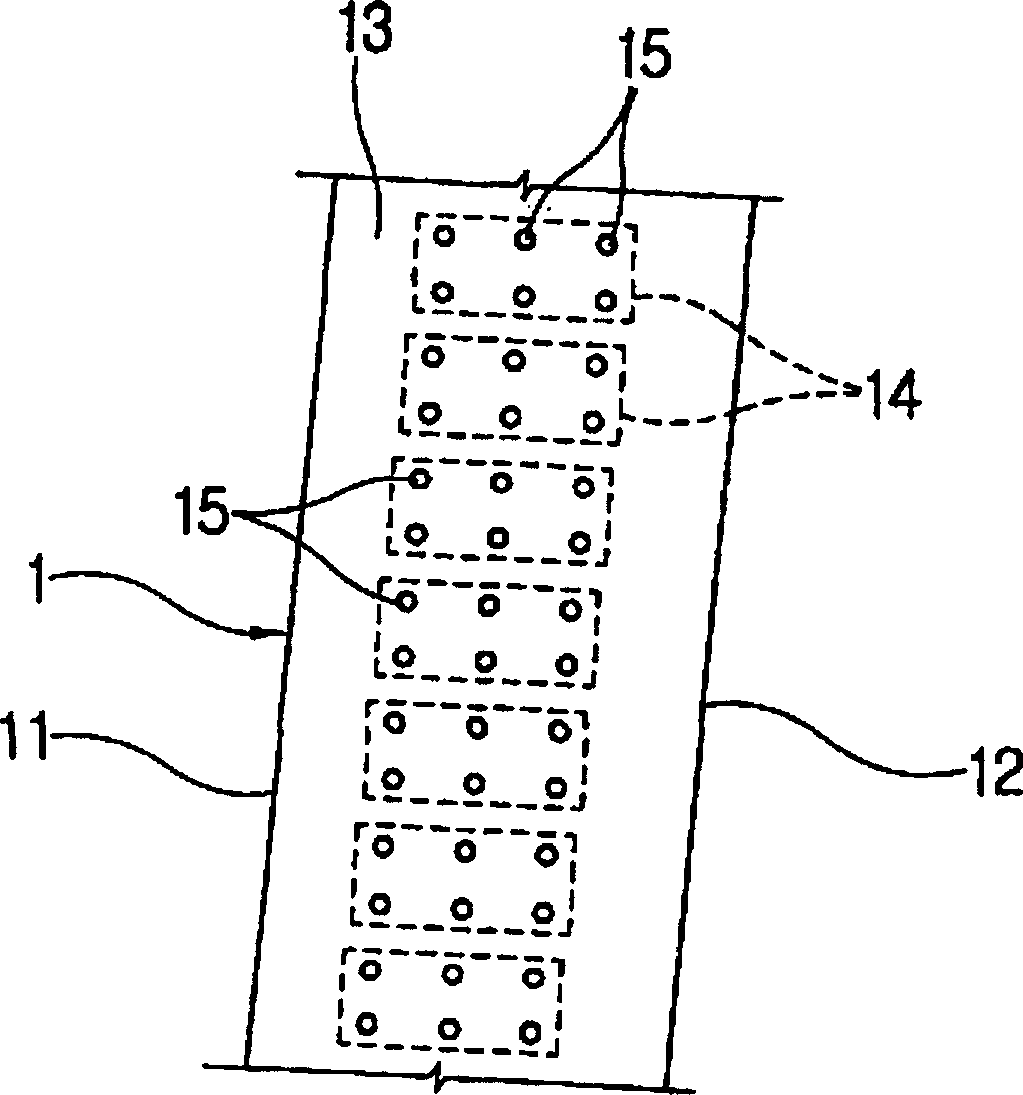

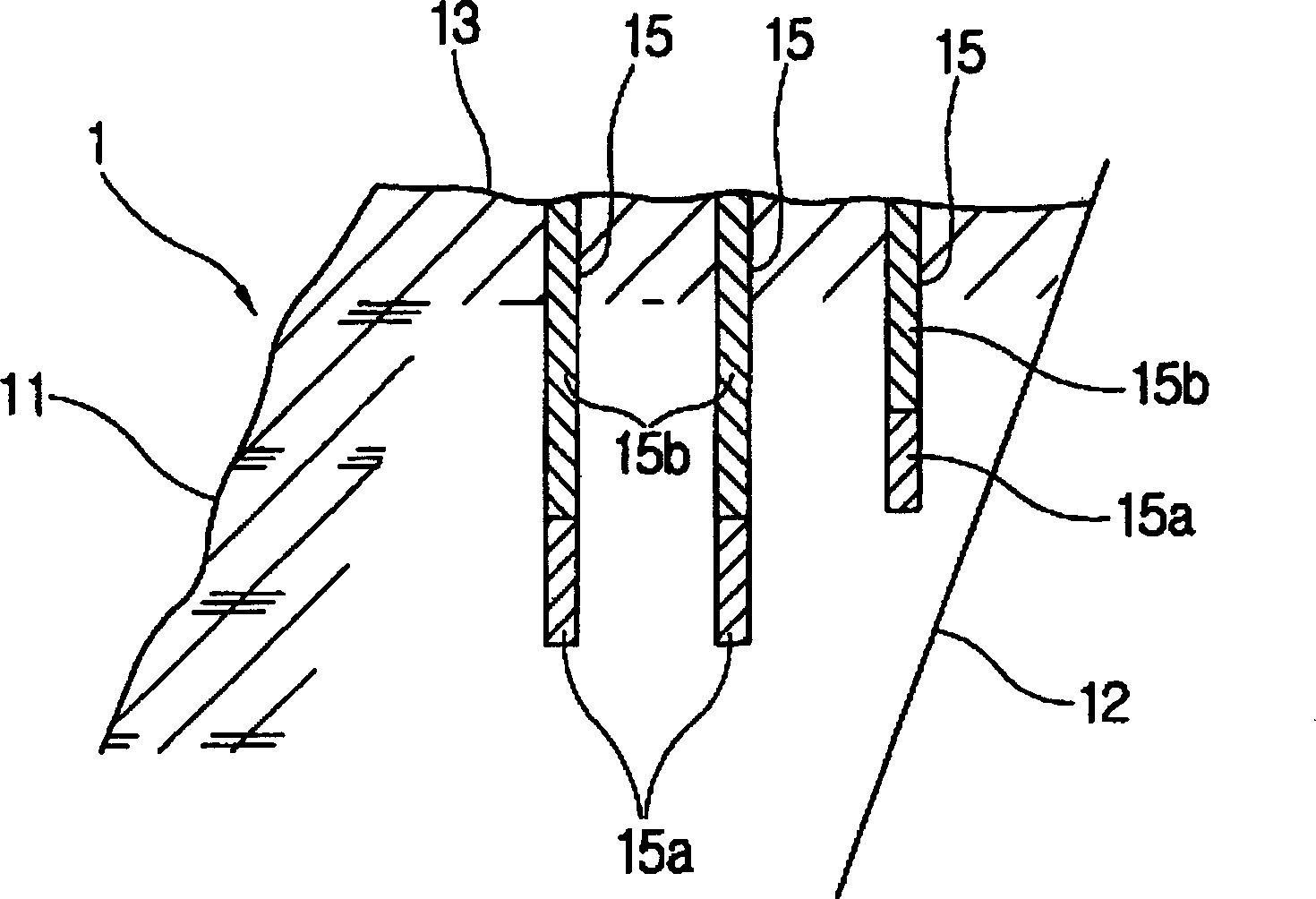

[0025] exist Figure 1-8 Among them, symbol 1 represents the rock formation formed on one side or both sides of the road during the opening or widening construction of mountain roads or coastal roads, and symbol 2 in the figure represents the blasting shield of the present invention.

[0026] First, the structure of the blast shield 2 used in the relaxation blasting method of the present invention will be described.

[0027] The above-mentioned blasting shield 2 is made of an iron plate member 21 with a thickness (above 3 mm) that can fully withstand the blasting force of the explosives loaded into the blasting hole, and is fixed on the bottom peripheral edge of the above-mentioned iron plate member 21 to prevent blasting noise and stones from flying. Elastic member 22, on the above-mentioned iron plate member 21 upper peripheral edge and its inner side transversely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com