Stator bonding nib

A stator, pointed wedge technology, applied in the direction of structural connection, connection with grounding device, manufacture of stator/rotor body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

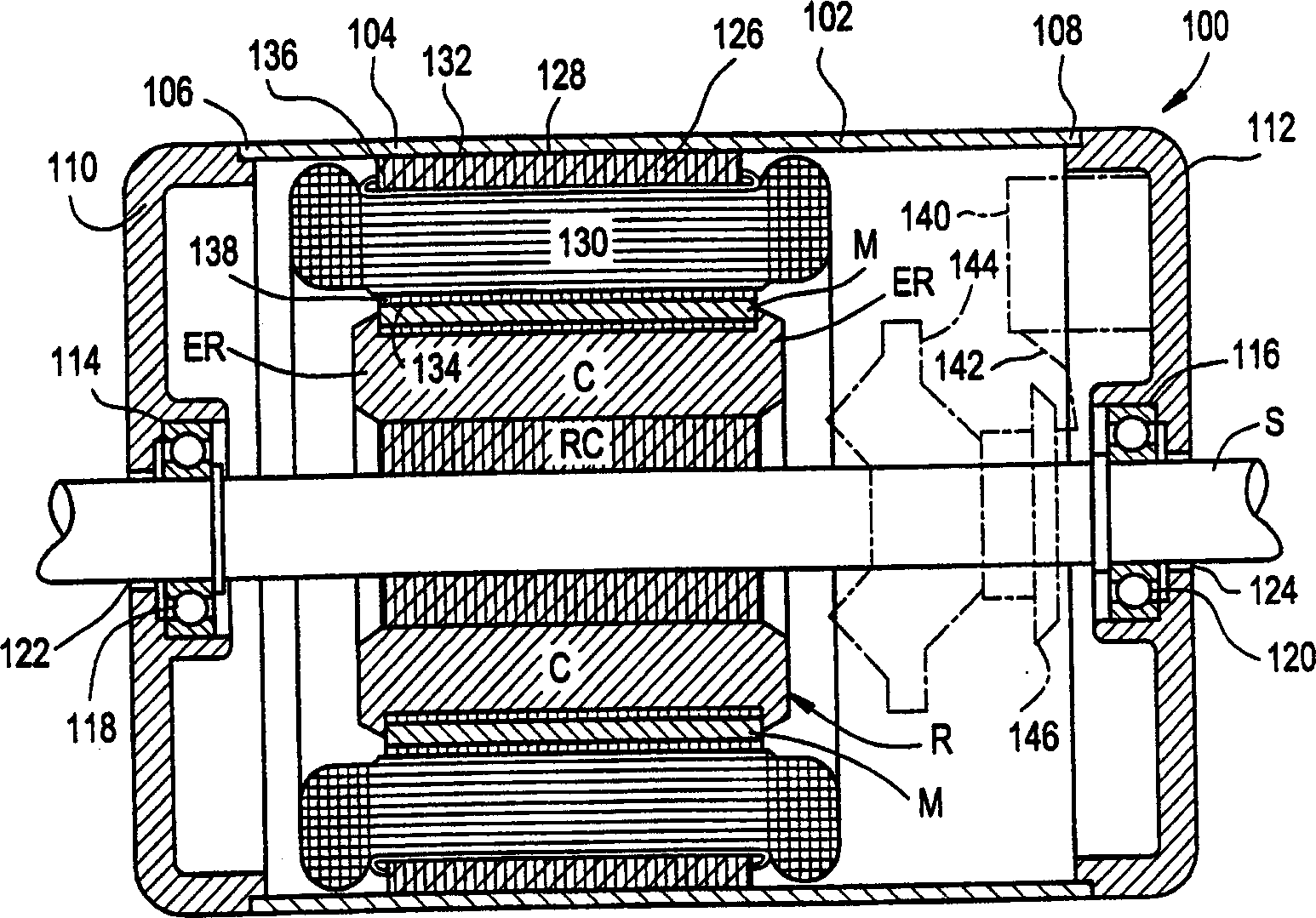

[0014] figure 1 It is a schematic diagram of an exemplary motor including a housing 102 with a housing 104 with second ends 106,108. Although the stator laminations are referred to as electric motor laminations in this article, it should be understood that the present invention is not limited to be implemented with any specific motor. The invention can be used for other motors.

[0015] The housing 104 includes a protective coating, which reduces the possibility of corrosion of the housing 104. In one embodiment, the protective coating is a paint that substantially covers the entire surface of the housing 104. An exemplary coating is a mixture of #CR-648Powercron resin and #CP-583Powercron, available from PPG Industries, P. O. Box 127, Springdale, Pennsylvania 15144. The first end shield 110 is connected to the end 106, and the second end shield 112 is connected to the end 108. The end shields 110, 112 contain the support portions 114, 116 of the bearing assemblies 118, 120. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com