A kind of metallographic etching solution of copper-gallium alloy and metallographic display method

A copper-gallium alloy and display method technology, which is applied in the field of copper-gallium alloy metallographic corrosion solution, can solve the problems of high cost and difficulty in controlling the corrosion degree, and achieve good material uniformity, shortened corrosion time, and good corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

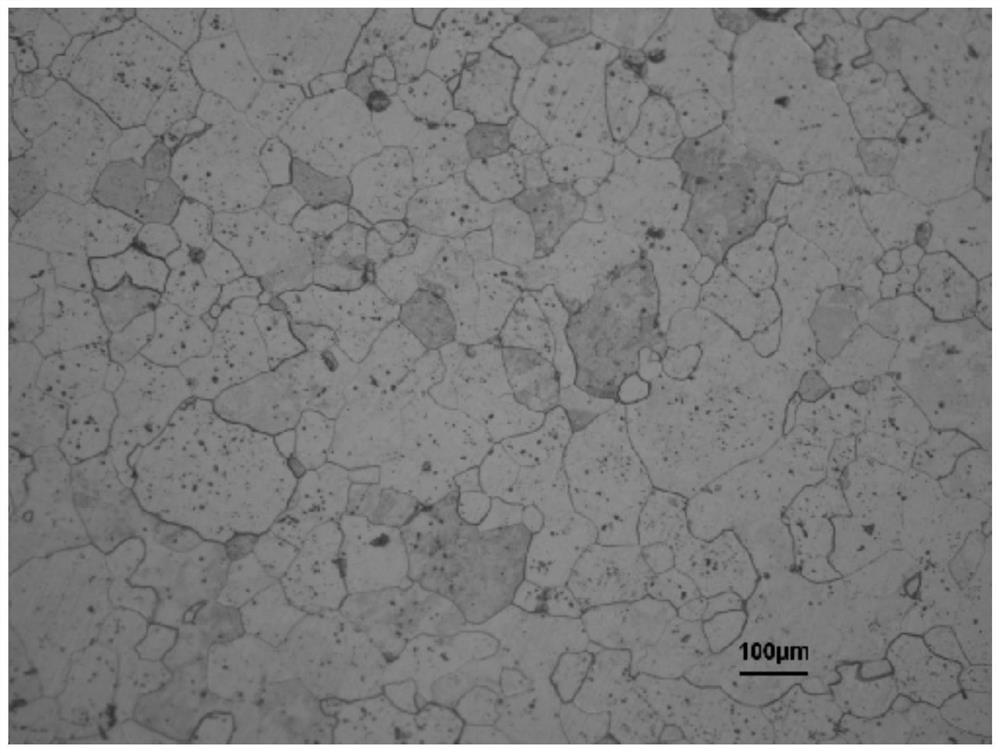

Embodiment 1

[0051] The mass fraction ratio of the copper-gallium alloy in this embodiment is Ga:Cu(Wt%)=20:80

[0052] (a) Cut the copper gallium alloy into a square sample with a size of 12mm*12mm*25mm; this size is easier to hold and thus easier to operate;

[0053] (b) first-stage grinding: select 300 mesh sandpaper to be installed on the grinding machine, use water as a wetting agent for grinding, select a 12mm*12mm surface as a grinding surface, the grinding machine rotational speed is 150r / min, and the grinding time is 15 minutes; The cutting marks on the polished surface can be polished off;

[0054] (c) Second-stage grinding: wash the sample with clean water, replace the sandpaper on the grinding machine with 600 mesh, and the grinding direction of the sample is 90° from the scratches of the first-stage grinding Angle, the grinding machine speed is 150r / min, continue grinding the grinding surface, grinding time is 15 minutes;

[0055] (d) third stage grinding: the difference bet...

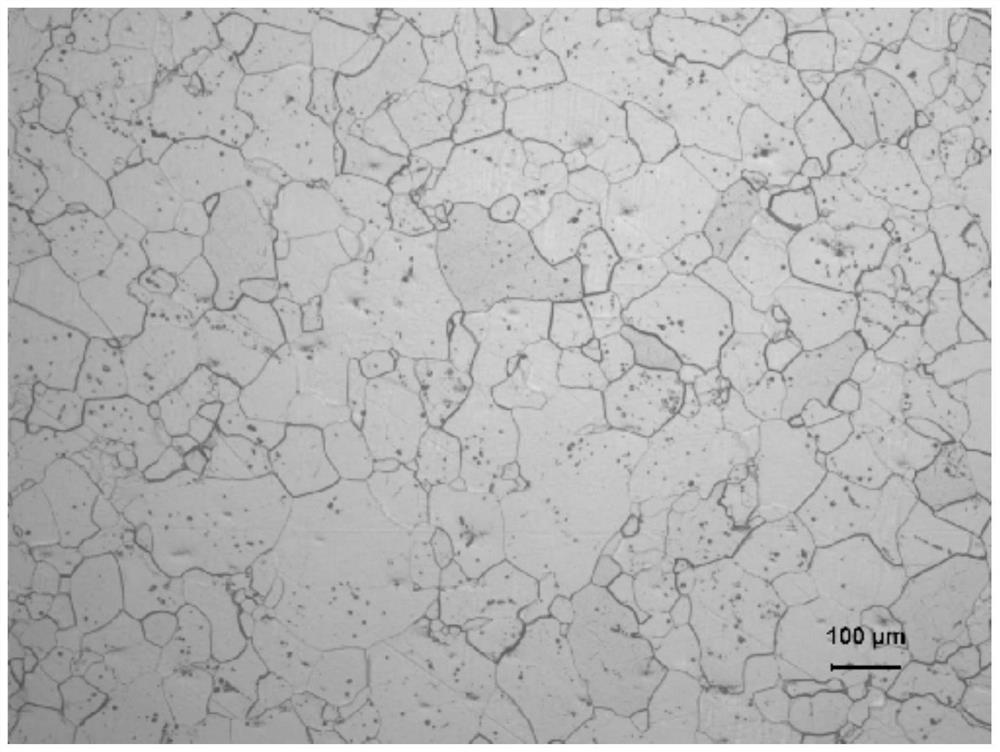

Embodiment 2

[0062] The mass fraction ratio of the copper-gallium alloy in this embodiment is Ga:Cu(Wt%)=45:55

[0063] (a) Cut the copper gallium alloy into a square sample with a size of 5mm*5mm*15mm; this size is easier to hold and thus easier to operate;

[0064] (b) grinding in the first stage: select 60 mesh sandpaper to be installed on the grinding machine, use water as a wetting agent to grind, select a 5mm*5mm surface as the grinding surface, the grinding machine rotating speed is 100r / min, and the grinding time is 5 minutes; The cutting marks on the polished surface can be polished off;

[0065] (c) Second-stage grinding: wash the sample with clean water, replace the sandpaper on the grinding machine with 500 mesh, and the grinding direction of the sample is 60° from the scratches of the first-stage grinding Angle, the grinding machine speed is 100r / min, continue grinding the grinding surface, grinding time is 5 minutes;

[0066] (d) third stage grinding: the difference between...

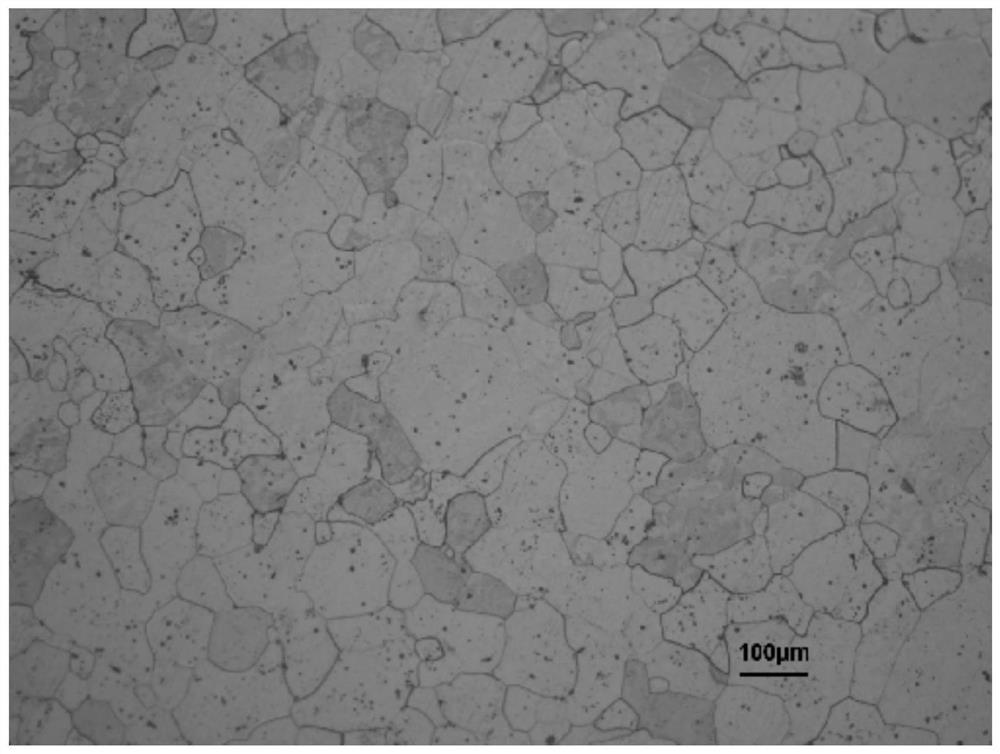

Embodiment 3

[0073] The mass fraction ratio of the copper-gallium alloy in this embodiment is Ga:Cu(Wt%)=10:90

[0074] (a) Cut the copper-gallium alloy into a square sample with a size of 20mm*20mm*45mm; this size is easier to hold and thus easier to operate;

[0075] (b) first stage grinding: select 400 mesh sandpaper to be installed on the grinding machine, use water as a wetting agent to grind, select a 20mm*20mm surface as a grinding surface, the grinding machine rotating speed is 200r / min, and the grinding time is 20 minutes; The cutting marks on the polished surface can be polished off;

[0076] (c) Second-stage grinding: wash the sample with clean water, replace the sandpaper on the grinding machine with 900 mesh, and the grinding direction of the sample is 120° from the scratches of the first-stage grinding Angle, the grinding machine speed is 200r / min, continue grinding the grinding surface, grinding time is 20 minutes;

[0077] (d) third stage grinding: the difference between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com