Internal combustion engine inner cone type atomization system

A technology of atomization system and internal combustion engine, which is applied in the direction of charging system, mechanical equipment, engine components, etc., which can solve the problems of too thick and uneven circumferential distribution of the mixed gas, and short penetrating distance of umbrella-shaped spray, so as to achieve rapid combustion and Perfect, uniform circumferential distribution, good atomization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

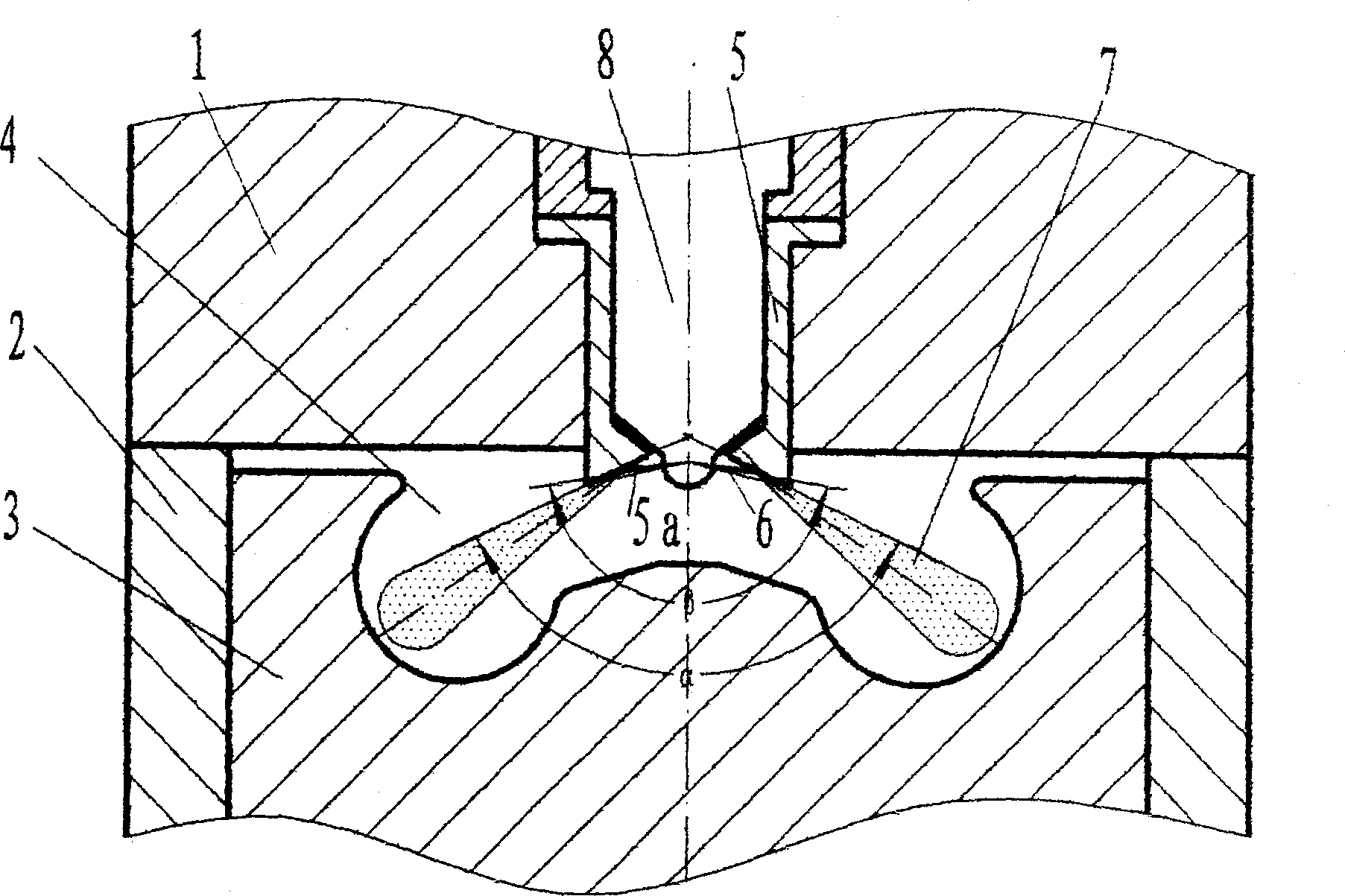

[0010] in figure 1 In the illustrated embodiment, the cylinder head (1), the cylinder liner (2) and the piston (3) form an ω-type combustion chamber (4), and a fuel injector (8) is installed in the middle of the cylinder head (1). The outer side of the mouth (8) is a sleeve (5), and the lower end of the sleeve (5) is provided with an inner cone type guide cone. When the fuel injection nozzle (8) sprays an oil jet (6) toward the inner cone surface (5a) of the guide cone, the primary oil jet (6) expands into a more uniform circumferential direction under the guidance of the inner cone surface The secondary oil beam (7) forms a more homogeneous combustible mixture under the action of the air flow in the combustion chamber (4).

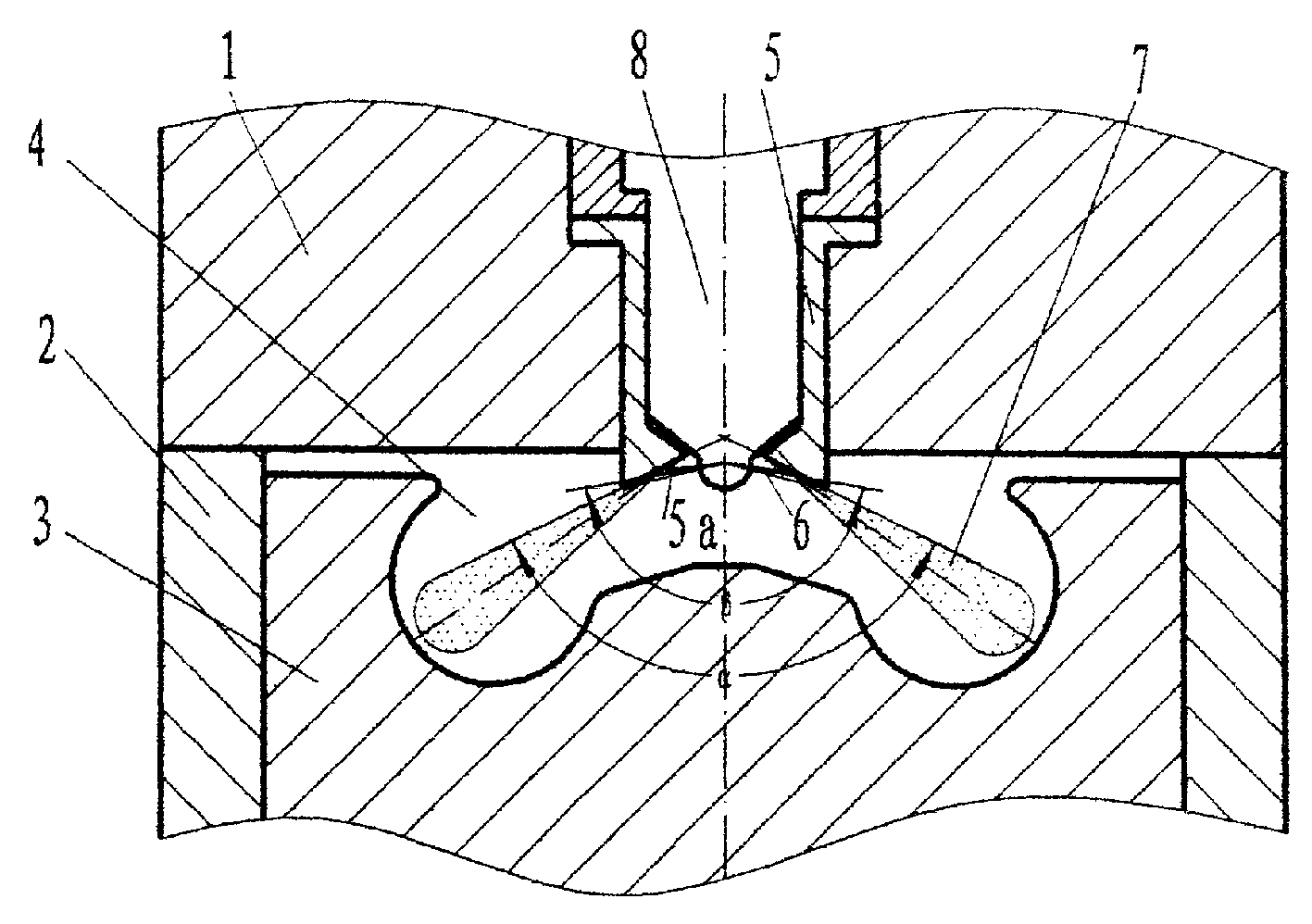

[0011] in figure 2 It shows that the inner cone guide cone is directly integrated with the cylinder head (1) and is located on the lower plane of the cylinder head (1) around the fuel injection nozzle (8).

[0012] In the above two embodiments, the same is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com