Coal-fired water heating furnace

A water heater, coal-burning technology, applied in water heaters, lighting and heating equipment, fluid heaters, etc., can solve the problems of heat loss, affecting the combustion effect, and easy discharge of smoke and dust into the atmosphere.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

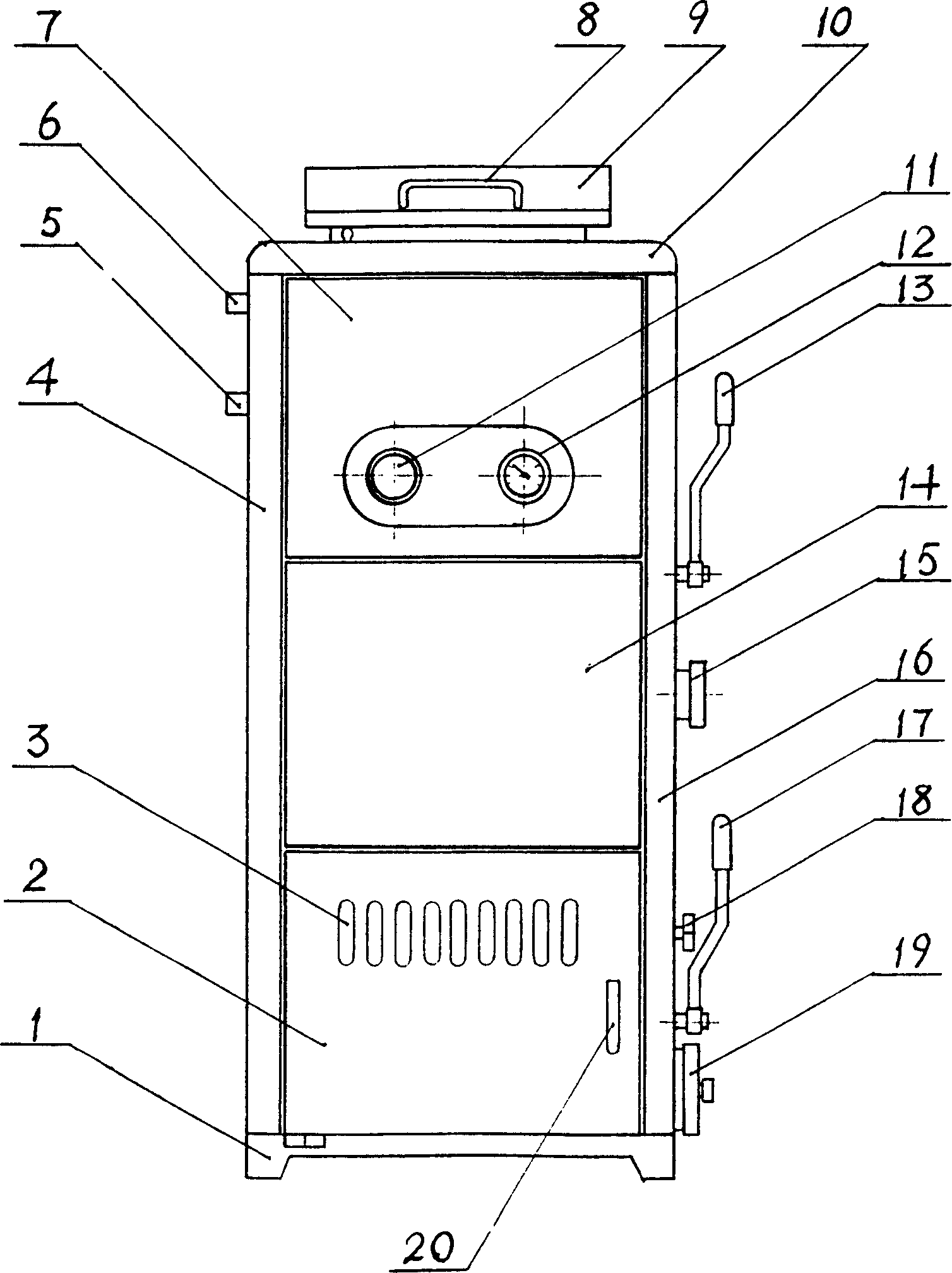

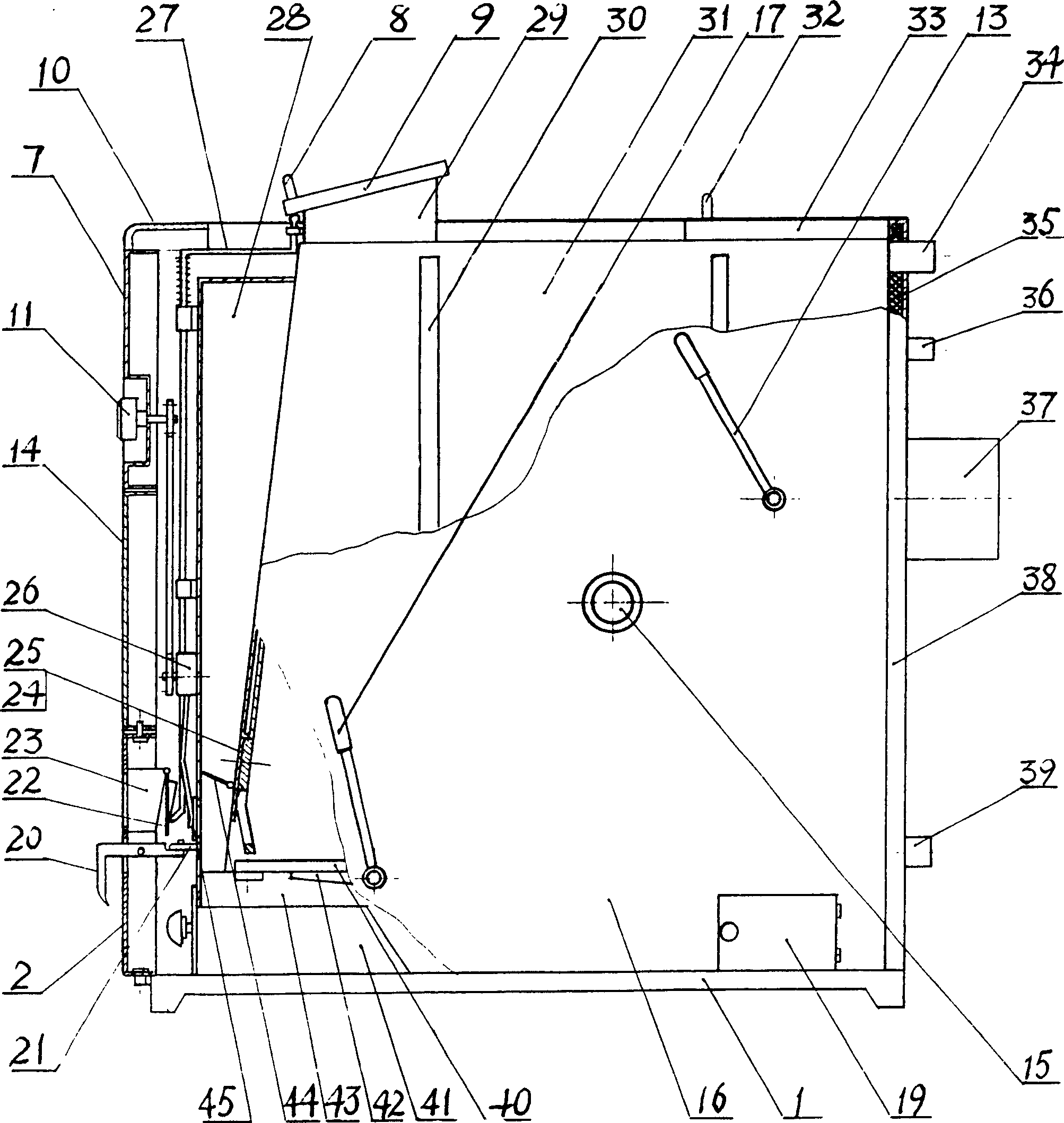

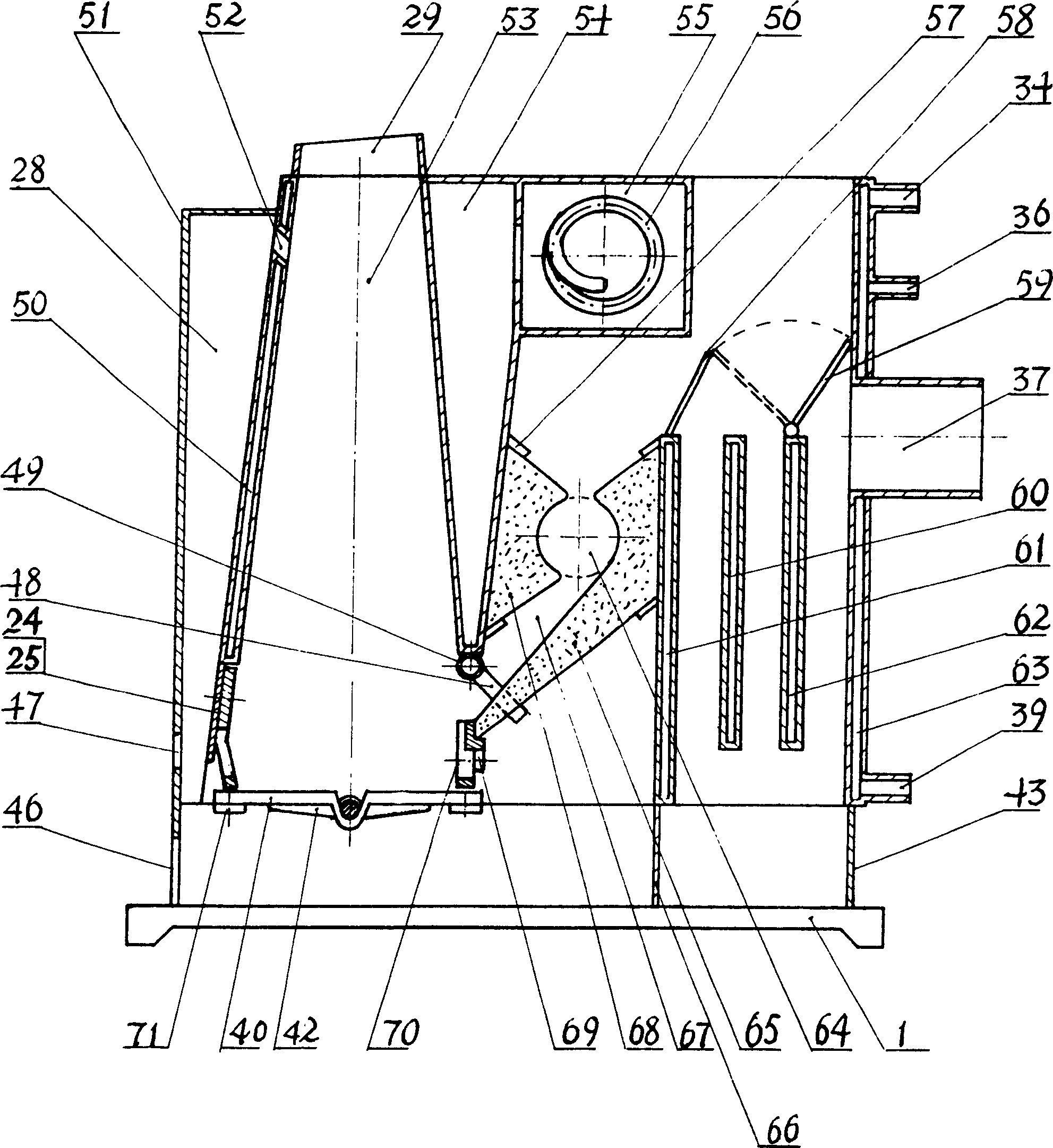

[0022] Such as figure 1 , figure 2 , image 3 Shown:

[0023]Above the rectangular bottom plate with 4 legs on the base 1, a circle of coaming plate 43 is welded around, which is divided into the ash chamber of the front part and the smoke chamber of the rear by a dividing plate 66, and there is a space in front of the ash chamber. Put into the rectangular opening 46 of the ash hopper 41, on one side of the dust chamber is a dust cleaning door 19 for removing dust, and on the top of the surrounding plate 43, the rear and two sides of the bottom of the combined heat exchange device 31 are welded. The combined heat exchange device 31 includes a front interlayer water jacket 50 and a rear interlayer water jacket 54 constituting the furnace 53 from front to back, a water exchange jacket 55 arranged laterally above the secondary combustion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com