Bonded optical disks and method and appts for producing same

A technology of optical discs and equipment, applied in the field of optical discs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

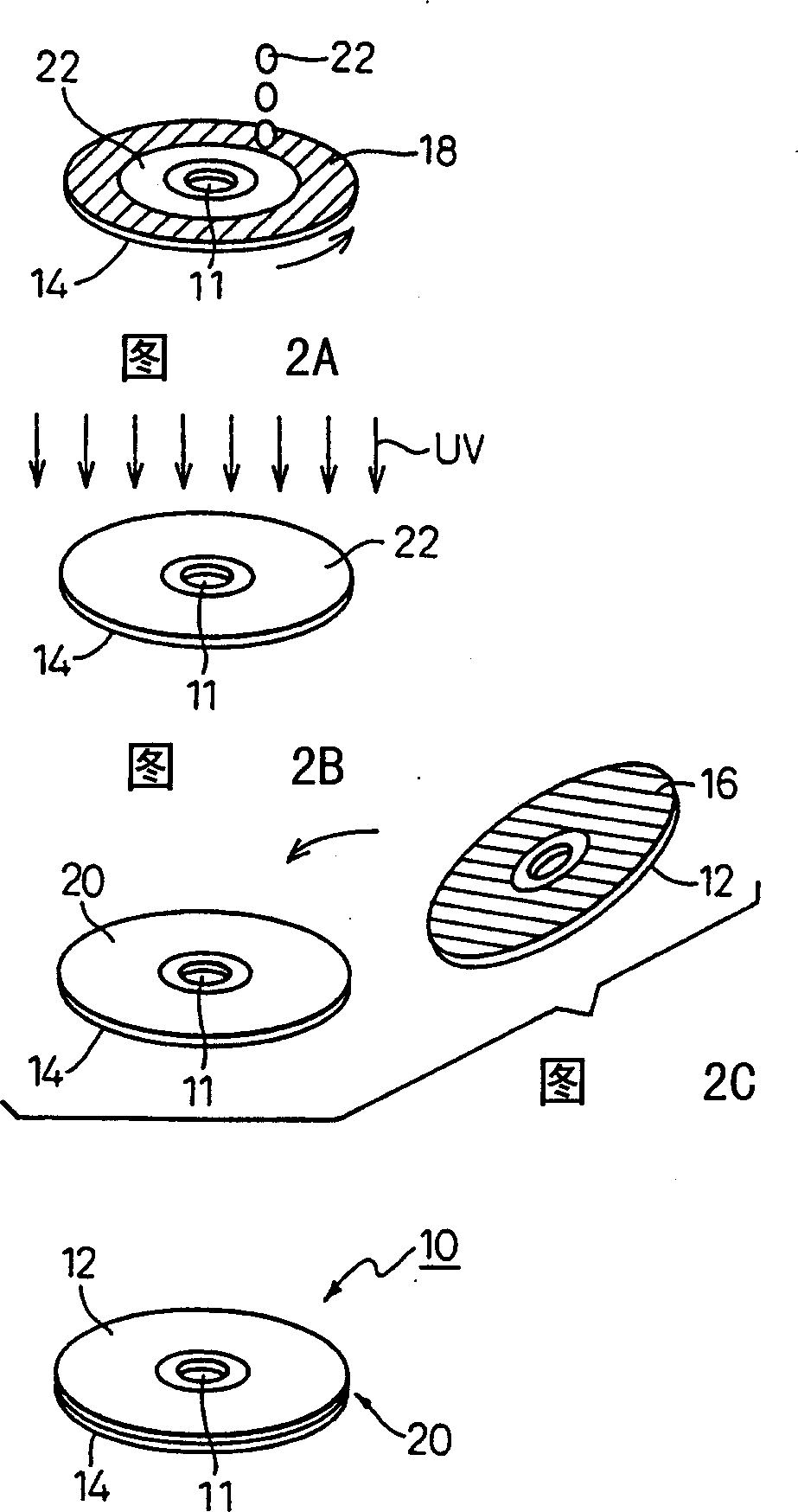

[0124] Prepare a mixed solution consisting of 90 parts of isooctyl acrylate, 10 parts of acrylic acid, and 0.04 parts of a photoinitiator manufactured by CIBA-GEIGY under the trade name "Irgacure 651" as a photoinitiator, and then place it in a nitrogen atmosphere.

[0125] The mixed solution is then irradiated with ultraviolet radiation having a wavelength of 200 to 400 nm from an ultraviolet source to effect photopolymerization. When the reaction proceeded to a viscosity of about 500 cps (measured with a Brookfield viscometer), the UV irradiation was stopped to prepare a pressure-sensitive adhesive precursor.

[0126] 0.08 parts of hexanediol diacrylate and 0.1 part of "Irgacure 651" were added to the pressure-sensitive adhesive precursor to prepare a pressure-sensitive adhesive precursor slurry.

[0127] Thereafter, the pressure-sensitive adhesive paste was uniformly spin-coated on a transparent circular substrate made of polycarbonate to form a 28 µm-thick coating.

[01...

example 2

[0131] 50 parts of 2-ethylhexyl carbitol acrylate, 50 parts of oligomer (manufactured by Shin-Nakamura Chemical Co., Ltd., trade name "NK-Oligo U-340AX"), and 1 part of photosensitive An initiator (manufactured by Merck (Japan) under the trade name "Darocur 1173") was mixed together to prepare a pressure-sensitive adhesive precursor. The viscosity of the pressure-sensitive adhesive precursor was measured by the same method as in Example 1, and as shown in Table 1, was found to be 820 cps.

[0132] Spin-coat the pressure-sensitive adhesive precursor evenly on two circular substrates made of polycarbonate in the same manner as Example 1, to a thickness of 28 μm, and then make the pressure-sensitive adhesive The precursor is fully cured. As a result, it was found that a 28 µm thick pressure-sensitive adhesive layer was uniformly formed on the circular substrate. The storage modulus and gel fraction of the pressure-sensitive adhesive layer were measured in the same manner as in ...

example 3

[0135] 80 parts of n-butyl acrylate and 0.04 parts of "Darocur 1173" as a photoinitiator were mixed, and the mixture was placed in a nitrogen atmosphere and then irradiated with ultraviolet radiation to prepare a pressure-sensitive adhesive paste.

[0136] Then 10 parts of urethane acrylate "UV3000B" (manufactured by Nippon synthetic Chemical Industry Co., Ltd.), 10 parts of hydroxypropyl acrylate, and 1 part of "Darocur 1173" were added to this pressure-sensitive adhesive paste , to prepare a pressure-sensitive adhesive precursor, which had a viscosity of 480 cps when measured by the above method. The pressure-sensitive adhesive precursor was uniformly spin-coated on two circular substrates in the same manner as in Example 1 to a thickness of 28 µm, and the coating was completely cured by ultraviolet irradiation in a nitrogen atmosphere. In this case, it was found that a 28 μm thick pressure-sensitive adhesive layer could be uniformly formed on the circular substrate. The st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com