Storage media and producing method thereof

A storage medium and manufacturing method technology, which is applied in the manufacture of optical record carriers, information storage, and recorded information storage, etc., can solve the problems of heat accumulation, diffusion, and data fineness affecting the recording quality of storage media, etc., so as to ensure the recording quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The storage medium and its manufacturing method according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference symbols.

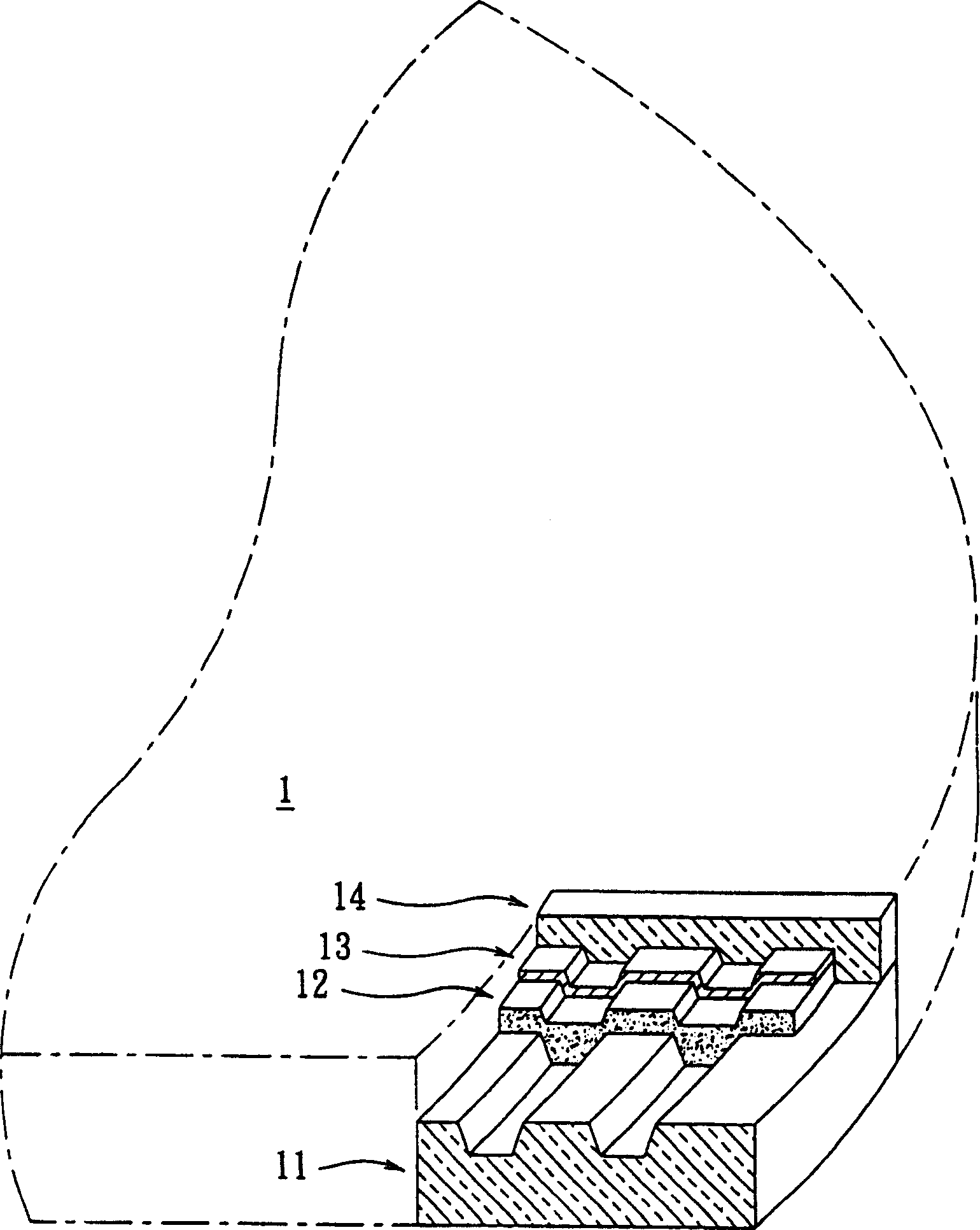

[0032] Please refer to image 3 As shown, the storage medium 4 according to the preferred embodiment of the present invention includes a substrate 41 , a recording layer 42 , a heat conducting film layer 43 , a reflective layer 44 , and a protective layer 45 .

[0033] In the present embodiment, the substrate 41 is a transparent substrate, which can be the substrate of CD-R or CD-RW (thickness is 1.2mm), DVD-R or DVD-RW substrate (thickness is 0.6mm). ); In addition, the substrate 41 can also be a substrate of DVD-RAM, Blu-ray storage medium or holographic data storage medium. Generally speaking, those skilled in the art form the substrate 41 by injection molding.

[0034] The recording layer 42 is formed on the substrate 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com