Speed multiplying reducing writing control method for CD read writer

A control method and technology of a burner, which are applied in optical recording/reproducing/erasing methods, recording/reproducing with optical methods, optical recording heads, etc. failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

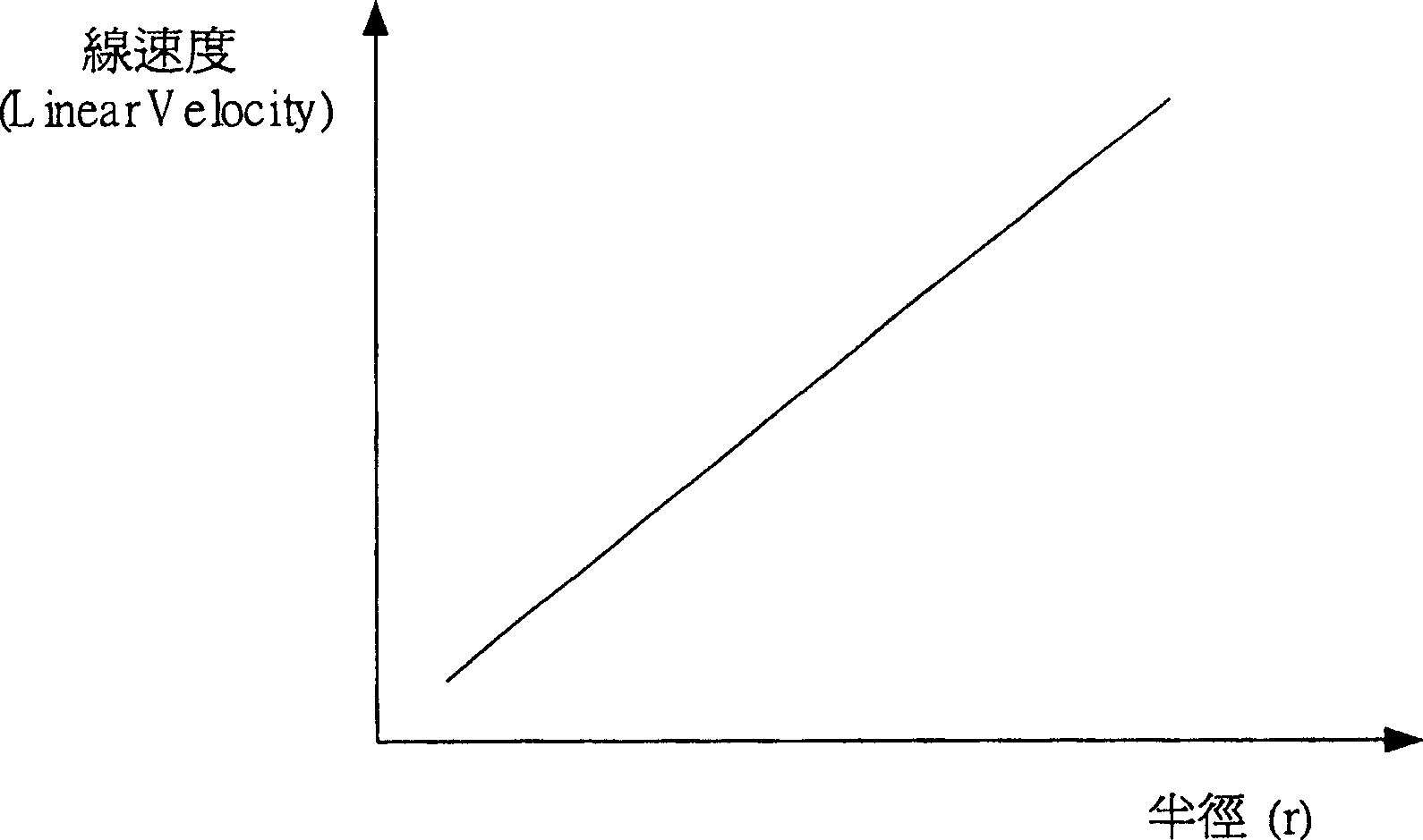

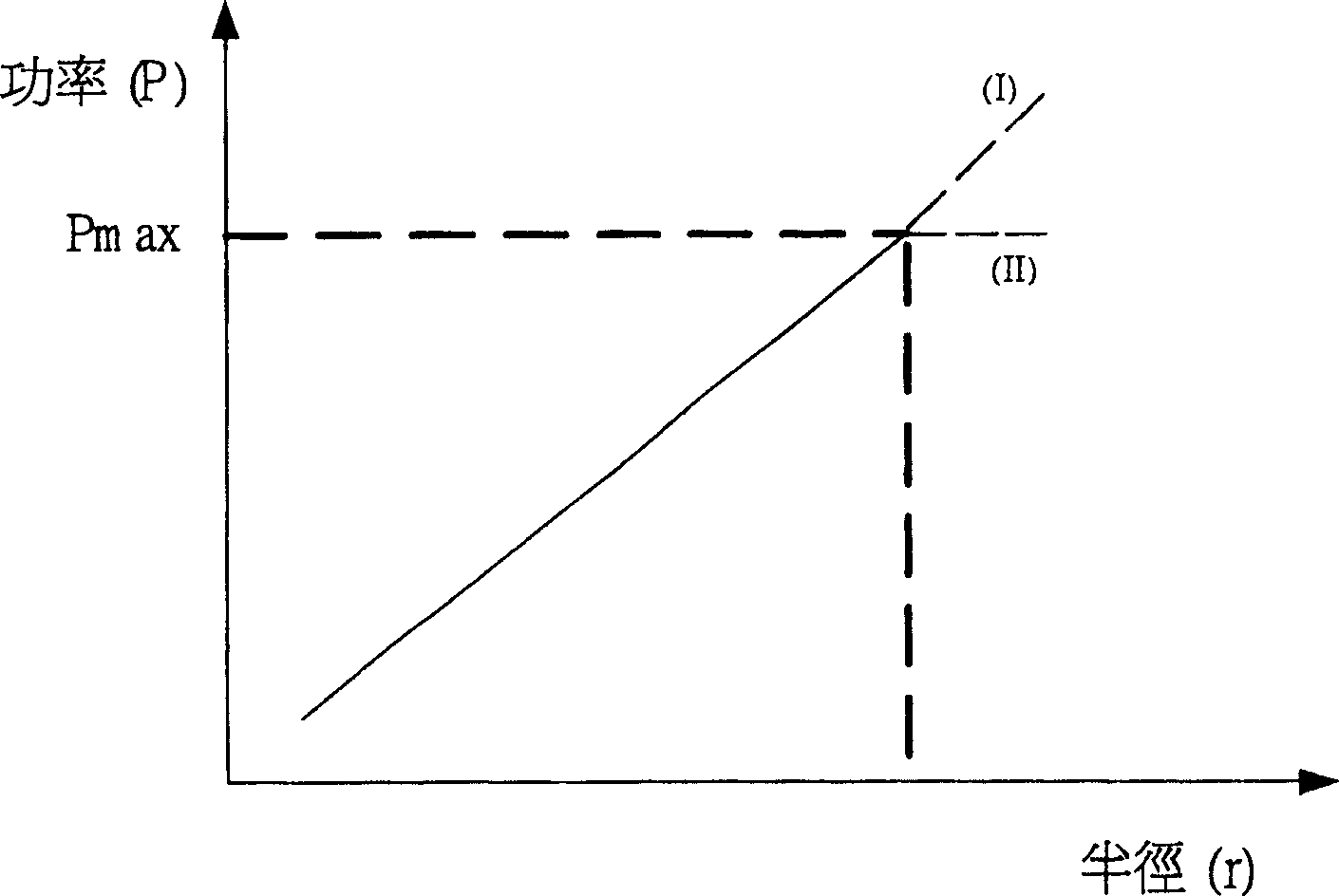

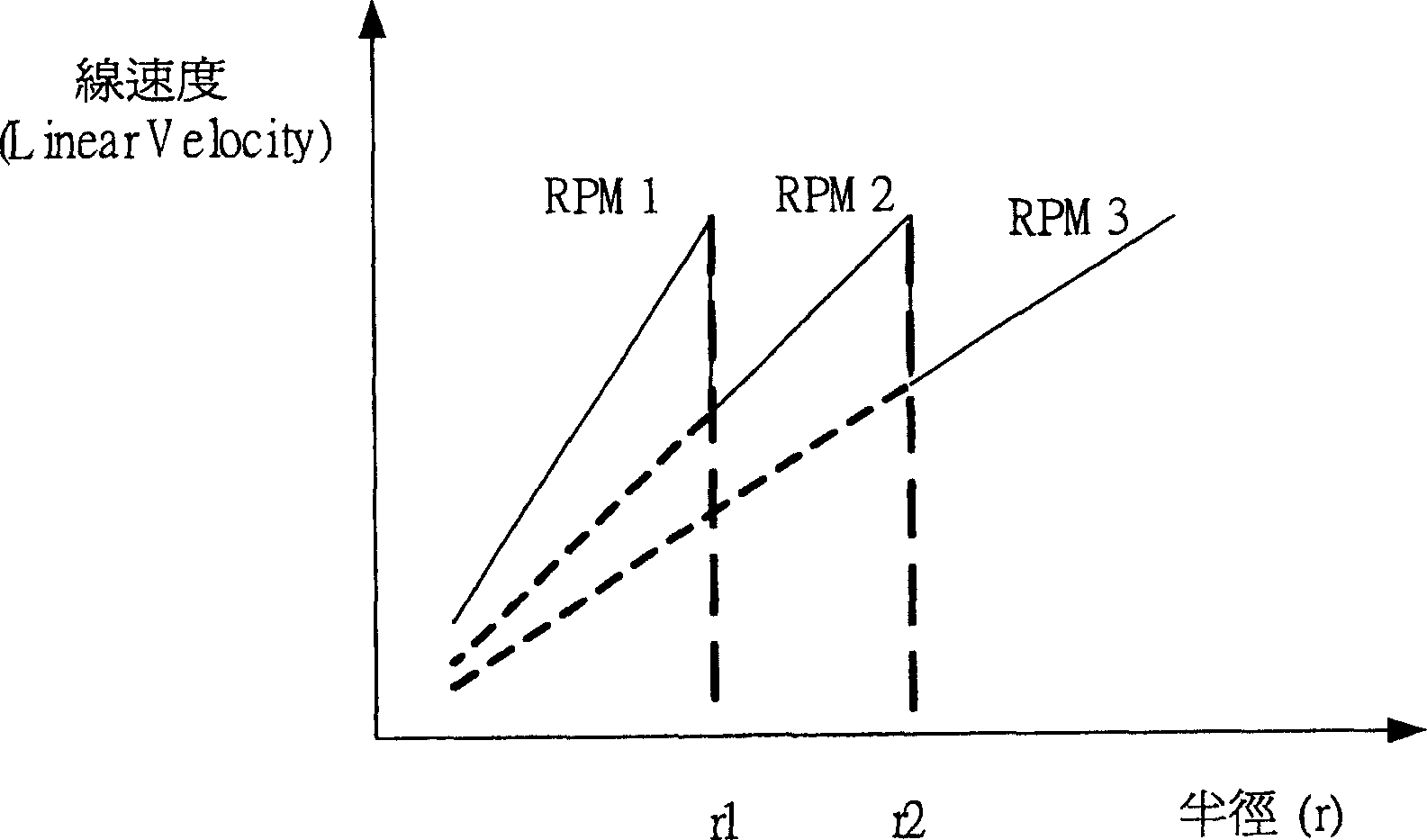

[0017] Please refer to FIG. 2(A), which shows the relationship between the linear velocity of the recordable optical disc drive and the radius of the optical disc according to the first embodiment of the present invention. FIG. 2(B) shows the relationship between the output power of the laser diode and the radius of the optical disc in the recordable optical disc drive according to the first embodiment of the present invention. First, set the optical disc drive to rotate at a first constant angular speed (RPM1). At this time, the output power of the laser diode will vary with the burning position on the optical disc, that is, the closer to the outer line of the optical disc The greater the speed, the greater the output power of the laser diode. Assume that when the spot formed by the laser beam is r1 away from the center of the optical disc, when the output power of the laser diode reaches a maximum value Pmax, the burning operation is suspended.

[0018] Next, the rotational ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com